At its core, the primary safety concerns associated with Chemical Vapor Deposition (CVD) stem directly from the materials it uses. The process relies on precursor chemicals that are often highly flammable, toxic, and corrosive, creating significant risks for personnel, equipment, and the environment that demand stringent control.

The fundamental challenge of CVD safety is not just handling dangerous chemicals, but managing a complex system where high vacuum, high temperatures, and reactive gases interact. True safety comes from an integrated approach, treating the entire process—from gas source to exhaust—as a single hazardous environment.

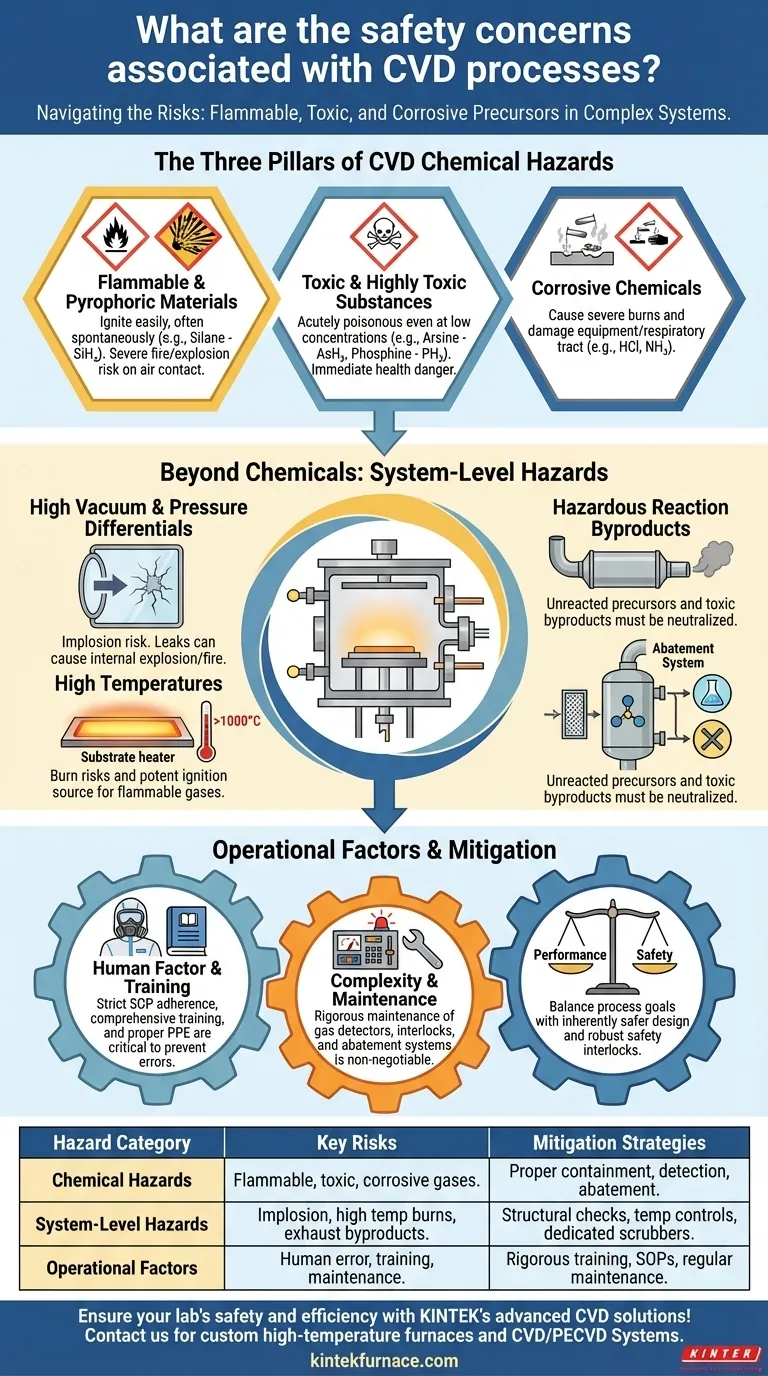

The Three Pillars of CVD Chemical Hazards

The most immediate dangers in any CVD process are the precursor gases and their byproducts. These can be broadly categorized into three distinct types of hazards.

Flammable and Pyrophoric Materials

Many CVD precursors are flammable, meaning they can ignite in the presence of an ignition source and an oxidizer like air.

A more extreme and common subclass is pyrophoric gases, such as silane (SiH₄). These materials spontaneously ignite upon contact with air, creating a severe fire and explosion risk if a leak occurs.

Toxic and Highly Toxic Substances

The precursors and reaction byproducts in CVD can be acutely toxic, posing an immediate danger to life and health upon exposure.

Gases like arsine (AsH₃) and phosphine (PH₃), used in the semiconductor industry for doping films, are extremely poisonous even at very low concentrations. Proper containment and exhaust management are therefore critical.

Corrosive Chemicals

Corrosive substances, such as hydrogen chloride (HCl) or ammonia (NH₃), are frequently used as precursors or for in-situ chamber cleaning.

These chemicals can cause severe burns upon contact with skin and are highly damaging to the respiratory tract if inhaled. They also attack incompatible materials, which can compromise the integrity of gas lines and equipment over time, leading to leaks.

Beyond Chemicals: System-Level Hazards

A comprehensive view of CVD safety extends beyond the chemical properties to the operational conditions of the equipment itself. The process environment creates its own distinct set of risks.

High Vacuum and Pressure Differentials

CVD systems operate under high vacuum, creating a massive pressure difference between the chamber interior and the outside atmosphere. A structural failure could lead to a dangerous implosion.

More critically, a small leak allows atmosphere to enter the chamber. If pyrophoric or flammable gases are present, this can lead to an explosion or fire inside the process chamber.

High Temperatures

The deposition process is often thermally driven, requiring substrate temperatures of several hundred or even over a thousand degrees Celsius.

This introduces obvious burn risks and serves as a potent ignition source, compounding the danger posed by flammable gases in the event of a system breach.

Hazardous Reaction Byproducts

Not all precursor material is consumed in the reaction. The exhaust stream contains a mixture of unreacted precursors and new, often hazardous, chemical byproducts.

This effluent must be routed to a dedicated abatement system (or scrubber) that neutralizes the hazardous materials before they are safely vented to the atmosphere. Failure of the abatement system is a major safety and environmental incident.

Understanding the Trade-offs and Pitfalls

Effective safety management requires acknowledging the inherent conflicts between process goals and absolute safety. The most common failures occur when these trade-offs are not respected.

The Need for Reactive Precursors

Often, the most chemically reactive and thus most hazardous precursors produce the highest quality films at the desired speed. There is a direct trade-off between using a more stable, safer precursor and achieving optimal process results.

The Complexity of Safety Systems

Gas detection systems, hardware interlocks, and exhaust abatement systems add significant cost and complexity. Treating these as optional or failing to perform rigorous, regular maintenance is a critical error that negates their protective function.

The Human Factor: Training and Complacency

Even the most advanced safety system can be defeated by human error. Inadequate training on standard operating procedures, emergency protocols, and the proper use of Personal Protective Equipment (PPE) remains a primary cause of incidents. Complacency in a familiar process is a constant threat.

Making the Right Choice for Your Goal

Your safety strategy should be tailored to your specific role and responsibilities within the CVD environment.

- If your primary focus is process design: Prioritize inherently safer design by selecting the least hazardous precursors that meet your film requirements and ensuring all safety interlocks are robust.

- If your primary focus is facility management: Implement a rigorous preventative maintenance schedule for all abatement systems, gas detectors, and life-safety equipment.

- If your primary focus is operator safety: Enforce strict adherence to standard operating procedures and mandate comprehensive, recurring training on both normal operation and emergency response.

By treating safety as a non-negotiable, integral component of the entire CVD process, you can effectively mitigate these inherent risks and operate with confidence.

Summary Table:

| Hazard Category | Key Risks | Mitigation Strategies |

|---|---|---|

| Chemical Hazards | Flammable/pyrophoric gases (e.g., silane), toxic substances (e.g., arsine), corrosive chemicals (e.g., HCl) | Use proper containment, gas detection, and exhaust abatement systems |

| System-Level Hazards | High vacuum implosion risks, high temperatures causing burns/ignition, hazardous byproducts in exhaust | Implement structural integrity checks, temperature controls, and dedicated scrubbers |

| Operational Factors | Human error, inadequate training, complacency, and system complexity | Enforce rigorous training, SOP adherence, and regular maintenance schedules |

Ensure your lab's safety and efficiency with KINTEK's advanced CVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces, including CVD/PECVD Systems, tailored for diverse laboratories. Our deep customization capabilities precisely meet your unique experimental needs, helping you mitigate risks from flammable, toxic, and corrosive chemicals while optimizing performance. Don't compromise on safety—contact us today to discuss how our expertise can protect your team and enhance your processes!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition