At its core, Chemical Vapor Deposition (CVD) is a manufacturing process that builds a high-purity, solid material layer on a surface, atom by atom. It achieves this by introducing specific gases, known as precursors, into a reaction chamber where they are energized, typically by heat. These gases react and decompose, depositing a thin, solid film onto a target object, or substrate, with exceptional precision.

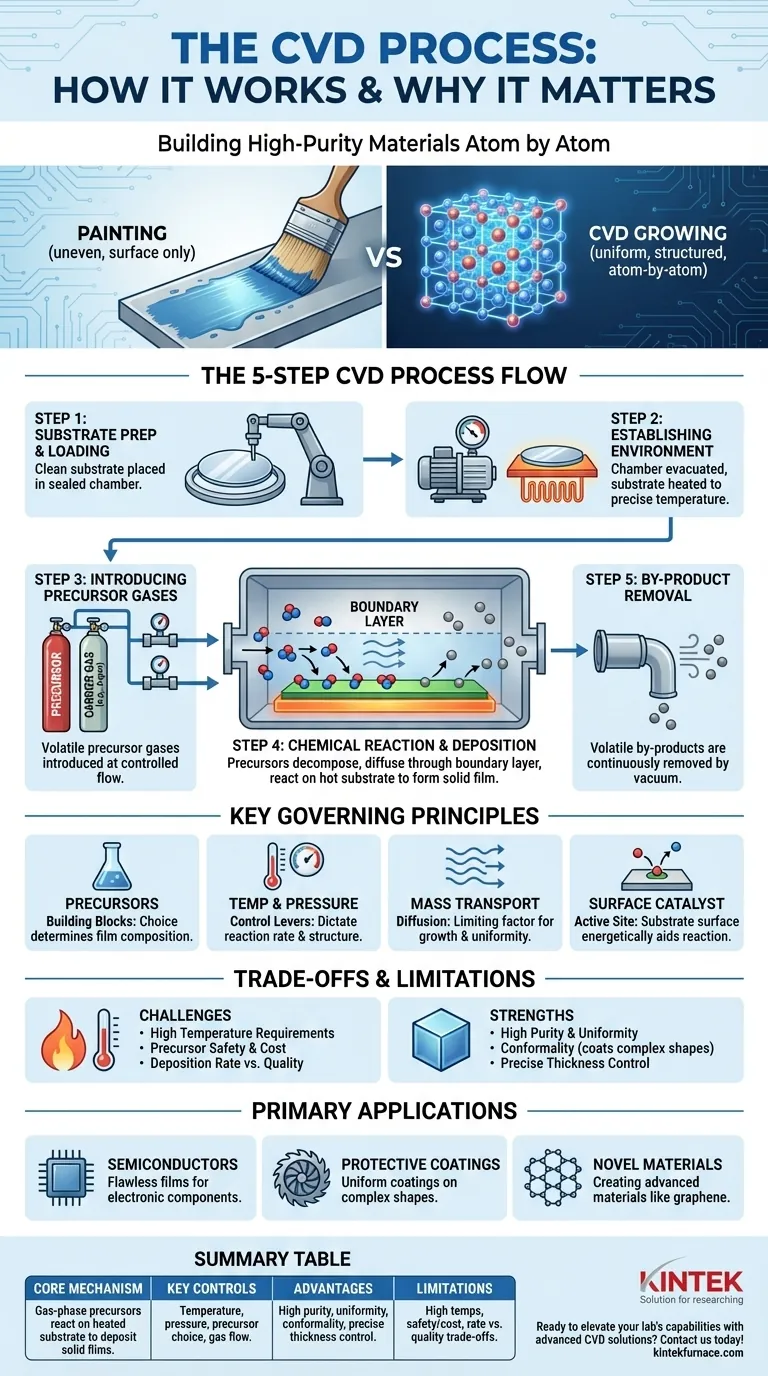

The fundamental challenge in advanced manufacturing is creating perfectly uniform, atomically precise thin films. CVD solves this not by "painting" a material on, but by "growing" it from a gaseous phase, offering unparalleled control over the film's thickness, composition, and structure.

The Foundational Steps of the CVD Process

The CVD process can be understood as a sequence of carefully controlled events, each critical to the quality of the final film.

Step 1: Substrate Preparation and Loading

Before any deposition can occur, the substrate must be meticulously cleaned. Any contaminants, even microscopic dust particles, can prevent the film from adhering properly and create defects.

The cleaned substrate is then placed inside the reaction chamber, which is sealed to create a controlled environment.

Step 2: Establishing the Environment

The chamber is typically pumped down to a vacuum to remove all atmospheric gases. This ensures that only the intended precursor gases will participate in the reaction.

The substrate is then heated to a precise, elevated temperature. This temperature provides the necessary thermal energy to drive the chemical reactions that will form the film.

Step 3: Introducing Precursor Gases

Volatile precursor gases are introduced into the chamber at a controlled flow rate. These gases contain the chemical elements that will make up the final solid film.

Often, these precursors are diluted with an inert carrier gas, like argon or hydrogen, which helps to transport them uniformly over the substrate surface.

Step 4: The Chemical Reaction and Deposition

As the hot precursor gases flow near the heated substrate, the thermal energy causes them to decompose and react. This creates highly reactive atoms or molecules.

These species then diffuse across a thin, stagnant layer of gas known as the boundary layer and adsorb (stick) onto the hot substrate surface. It is here, on the surface itself, that the final chemical reaction occurs, forming a stable, solid film.

Step 5: By-product Removal

The chemical reactions that form the solid film also generate unwanted gaseous by-products.

These volatile by-products are not incorporated into the film. Instead, they are continuously removed from the chamber by the vacuum and exhaust system, keeping the reaction environment pure.

Key Principles That Govern CVD

The power of CVD comes from the precise control it offers over fundamental physical and chemical principles.

The Role of Precursors

Precursors are the essential building blocks. The choice of precursor chemistry directly determines the composition of the deposited film. For example, to create a silicon nitride film, you might use silane (SiH₄) and ammonia (NH₃) as precursors.

The Importance of Temperature and Pressure

Temperature and pressure are the primary control levers. Temperature provides the energy for precursor decomposition, and its level dictates the reaction rate and the film's crystal structure. Pressure influences gas density and flow characteristics within the chamber.

Mass Transport and the Boundary Layer

Gases do not instantly reach the substrate. They must first diffuse through the boundary layer. The rate of this diffusion can be the limiting factor for the entire process, influencing the film's growth rate and uniformity across the substrate.

Surface-Catalyzed Reaction

The hot substrate is not just a passive landing strip. Its surface often acts as a catalyst, providing an energetically favorable site for the chemical reaction to occur. This is why the film grows on the hot substrate rather than forming as "soot" in the gas phase.

Understanding the Trade-offs and Limitations

While powerful, CVD is not without its challenges. Understanding its limitations is key to using it effectively.

High Temperature Requirements

Many traditional CVD processes require extremely high temperatures (often >600°C). This makes them unsuitable for substrates that can be damaged by heat, such as plastics or electronic devices with previously fabricated components.

Precursor Safety and Cost

The gases used as precursors can be highly toxic, flammable, or corrosive. This necessitates complex and expensive safety protocols, handling equipment, and abatement systems.

Deposition Rate vs. Quality

There is often a direct trade-off between the speed of deposition and the quality of the film. Attempting to grow a film too quickly can lead to poor uniformity and structural defects.

Conformality and Shadowing

CVD is renowned for its ability to coat complex, three-dimensional shapes uniformly (a property called conformality). However, in non-ideal conditions, gas flow limitations can create "shadowing" effects, leading to thinner coatings in deep trenches or crevices.

Making the Right Choice for Your Goal

By understanding its core mechanics, you can see how CVD is tailored for specific outcomes.

- If your primary focus is ultimate purity and uniformity (e.g., semiconductors): The precise control over gas purity, temperature, and pressure in CVD is what enables the fabrication of flawless films essential for electronic components.

- If your primary focus is coating complex shapes (e.g., turbine blades): CVD's ability to deposit a film from a gaseous phase allows it to create uniform, protective coatings even inside intricate channels and on non-flat surfaces.

- If your primary focus is creating novel materials (e.g., graphene R&D): The versatility of CVD allows you to mix different precursors and fine-tune process parameters to grow a vast range of advanced materials with unique properties.

Understanding these principles transforms your view of CVD from a simple coating technique into a fundamental tool for building the future of advanced materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Chemical Vapor Deposition (CVD) |

| Core Mechanism | Gas-phase precursors react on a heated substrate to deposit solid films |

| Main Steps | 1. Substrate prep 2. Environment setup 3. Gas introduction 4. Reaction/deposition 5. By-product removal |

| Key Controls | Temperature, pressure, precursor choice, gas flow |

| Primary Applications | Semiconductors, protective coatings, graphene, and advanced materials |

| Advantages | High purity, uniformity, conformality, precise thickness control |

| Limitations | High temperatures, precursor safety/cost, deposition rate vs. quality trade-offs |

Ready to elevate your lab's capabilities with advanced CVD solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace systems like CVD/PECVD, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our strong deep customization ensures precise alignment with your unique experimental needs for superior thin-film deposition. Contact us today to discuss how we can support your research and production goals!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision