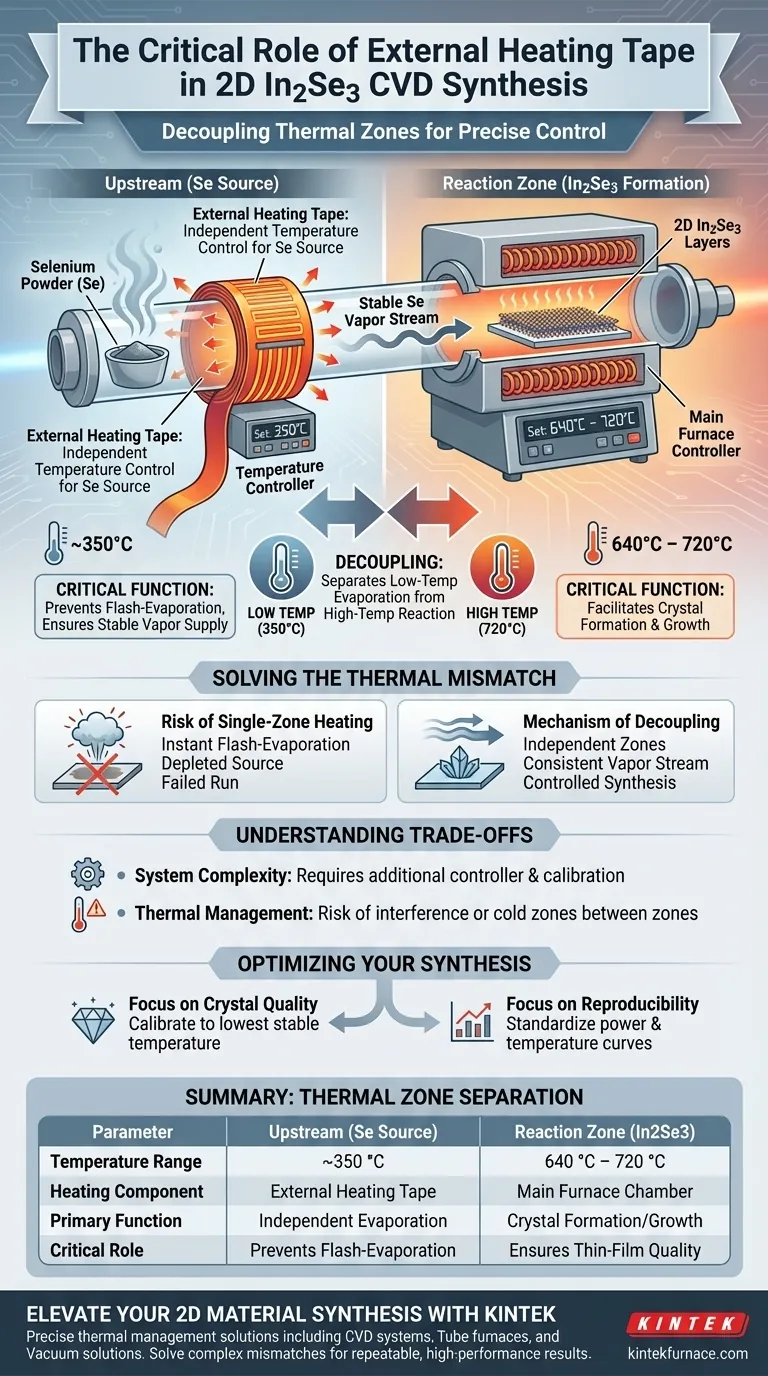

The critical regulatory function of the External Heating Tape is to provide independent temperature control for the upstream Selenium source. This component allows for the precise regulation of the Selenium evaporation rate, keeping it separate from the significantly higher thermal requirements of the main reaction zone.

The synthesis of 2D In2Se3 requires managing two conflicting temperature requirements simultaneously. The External Heating Tape resolves this by "decoupling" the low-temperature evaporation of Selenium from the high-temperature chemical reaction, ensuring a stable and continuous precursor supply.

Solving the Thermal Mismatch

The Disparity in Temperatures

The fundamental challenge in this Chemical Vapor Deposition (CVD) process is the vast difference in required temperatures.

Selenium powder, the upstream precursor, has a relatively low evaporation point of approximately 350 °C.

In contrast, the actual formation of 2D In2Se3 layers occurs in the reaction zone at temperatures ranging from 640 °C to 720 °C.

The Risk of Single-Zone Heating

Without an external regulatory mechanism, placing Selenium directly into a furnace set for the reaction temperature would be catastrophic to the process.

The Selenium would flash-evaporate almost instantly due to the excessive heat.

This would deplete the source material long before the target substrate reached the necessary conditions for crystal growth.

The Mechanism of Decoupling

Independent Thermal Zones

The External Heating Tape creates a distinct, controllable thermal zone separate from the main furnace.

This design decouples the precursor evaporation rate from the reaction zone temperature.

You are no longer forced to compromise the reaction temperature to save the precursor, nor burn off the precursor to achieve the reaction temperature.

Ensuring Stable Vapor Supply

By maintaining the tape at the specific evaporation point of Selenium, the system generates a consistent vapor stream.

This vapor travels downstream to the reaction zone, which is independently maintained at the higher crystallization temperature.

This ensures that the Selenium supply remains stable throughout the entire duration of the synthesis.

Understanding the Trade-offs

System Complexity

While essential for quality, introducing an External Heating Tape adds a layer of complexity to the CVD setup.

It requires an additional temperature controller and precise calibration to ensure the tape does not overheat locally.

Thermal Management Challenges

There is a risk of thermal interference between the external tape and the edge of the main furnace.

If the distance between these zones is not managed, radiant heat from the main furnace can inadvertently raise the source temperature.

Conversely, a gap that is too large can create a "cold zone" where vapor condenses before reaching the reaction site.

Optimizing Your Synthesis Setup

To effectively utilize the External Heating Tape in your CVD process, consider your specific experimental goals:

- If your primary focus is crystal quality: Calibrate the heating tape to the lowest possible temperature that sustains flow, preventing vapor saturation and uncontrolled nucleation.

- If your primary focus is process reproducibility: Record the exact power output and temperature curve of the heating tape to standardize the Selenium flux across different runs.

By mechanically separating the heating of the source from the heating of the reaction, you transform a chaotic evaporation process into a controlled, tunable variable.

Summary Table:

| Parameter | Upstream (Se Source) | Reaction Zone (In2Se3) |

|---|---|---|

| Temperature Range | ~350 °C | 640 °C – 720 °C |

| Heating Component | External Heating Tape | Main Furnace Chamber |

| Primary Function | Independent Evaporation | Crystal Formation/Growth |

| Critical Role | Prevents Flash-Evaporation | Ensures Thin-Film Quality |

Elevate Your 2D Material Synthesis with KINTEK

Precise thermal management is the difference between a failed run and high-quality 2D crystals. KINTEK provides industry-leading, customizable CVD systems, Tube furnaces, and Vacuum solutions designed to solve complex thermal mismatches like those found in In2Se3 synthesis.

Backed by expert R&D and precision manufacturing, our equipment empowers researchers to decouple critical variables for repeatable, high-performance results.

Ready to optimize your lab's high-temperature capabilities? Contact our technical experts today to discuss your unique synthesis needs.

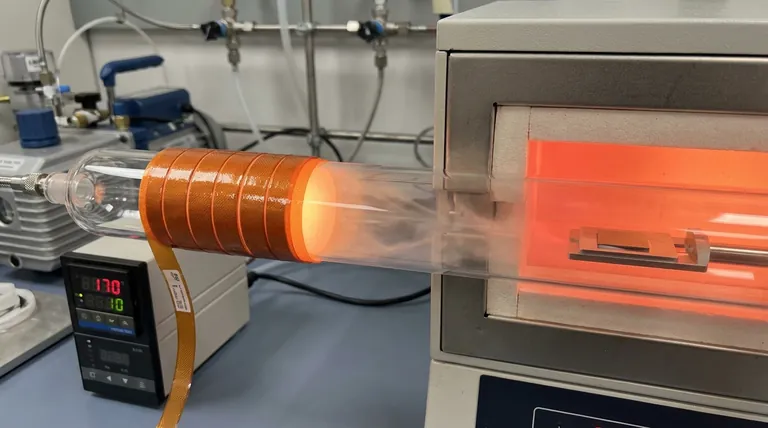

Visual Guide

References

- Dasun P. W. Guruge, Dmitri Golberg. Thermal Phase‐Modulation of Thickness‐Dependent CVD‐Grown 2D In<sub>2</sub>Se<sub>3</sub>. DOI: 10.1002/adfm.202514767

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the CVD process begin? Master Precise Film Deposition from the Start

- Why is a high-purity quartz tube selected for CVD MoP crystals? Unlock Maximum Purity in Semiconductor Growth

- What are the overall advantages of CVD technology across industries? Unlock High-Performance Material Engineering

- How does gaseous catalyst-assisted CVD benefit graphene production? Achieve Pristine Graphene for Advanced Electronics

- What is the function of an APCVD system in single-crystal bilayer graphene synthesis? Unlock Precision Growth

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What is Chemical Vapor Deposition (CVD) used for? Unlock High-Performance Thin Films for Your Applications

- What are the main advantages of CVD? Achieve Superior Film Deposition for Your Applications