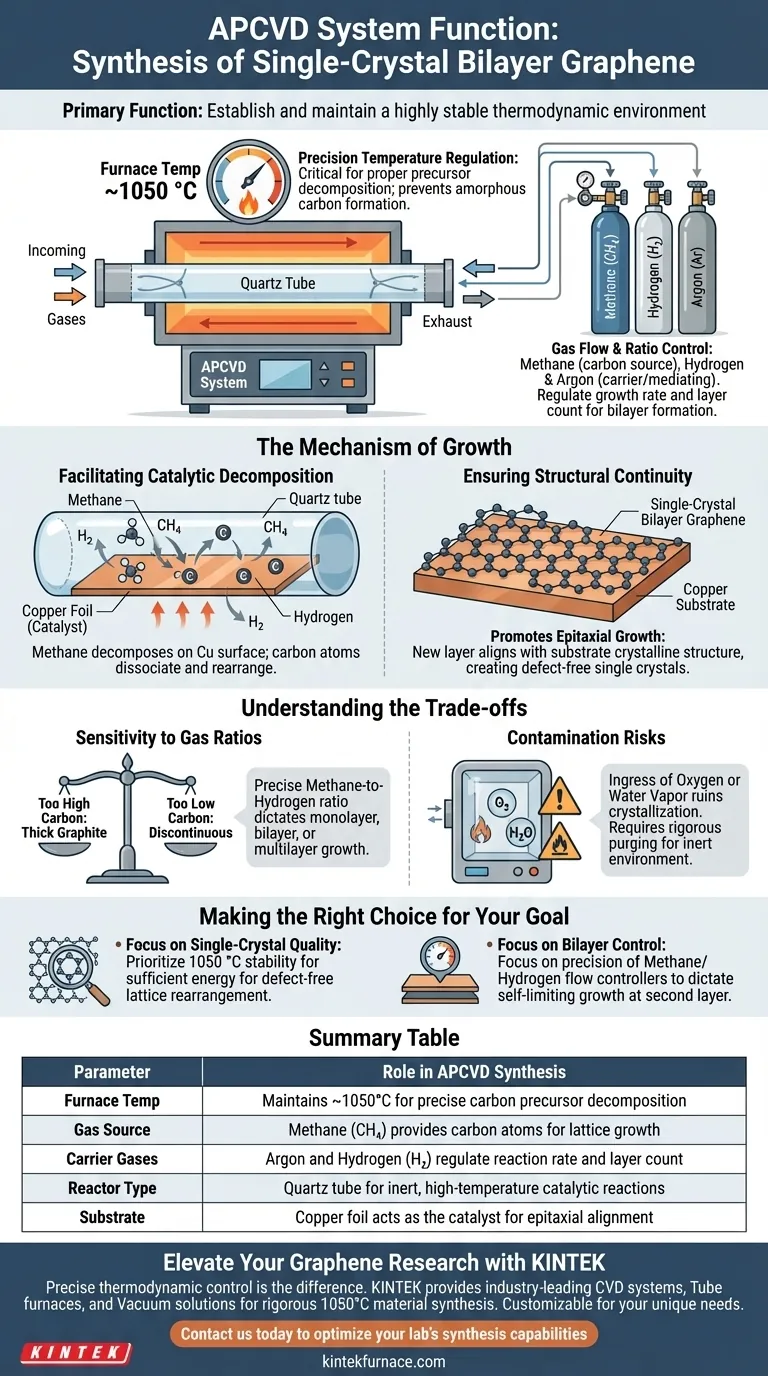

The primary function of an Atmospheric Pressure Chemical Vapor Deposition (APCVD) system is to establish and maintain a highly stable thermodynamic environment essential for the synthesis of single-crystal bilayer graphene. By precisely controlling furnace temperatures at approximately 1050 °C and managing the specific flow ratios of argon, hydrogen, and methane, the system enables the growth of large-area, high-quality films.

The APCVD system acts as a precision reactor that balances thermal energy and gas dynamics to facilitate the orderly arrangement of carbon atoms. Its core value lies in its ability to produce continuous, defect-free bilayer films that serve as fundamental materials for advanced research, such as alkali metal intercalation studies.

Establishing the Thermodynamic Environment

To synthesize single-crystal bilayer graphene, the system must move beyond simple heating. It must create a specific thermodynamic state where carbon atoms can settle into a precise lattice structure.

Precision Temperature Regulation

The system’s most critical role is maintaining the furnace temperature at typically 1050 °C.

At this specific thermal energy level, the system ensures the proper decomposition of carbon precursors. Deviating from this temperature can result in incomplete growth or the formation of unwanted amorphous carbon rather than crystalline graphene.

Gas Flow and Ratio Control

The APCVD system regulates the introduction of three key gases: methane, hydrogen, and argon.

Methane serves as the carbon source, while hydrogen and argon act as carrier and reaction-mediating gases. The system controls the flow ratios of these gases to dictate the growth rate and ensure the formation of exactly two layers of graphene, rather than a single monolayer or multilayer bulk graphite.

The Mechanism of Growth

The equipment does not just mix gases; it provides the physical stage for the chemical reaction to occur on a solid surface.

Facilitating Catalytic Decomposition

The system directs the gas mixture into a quartz tube reactor, where it interacts with a metal substrate, typically copper foil.

Under the high-temperature conditions provided by the furnace, the methane decomposes on the copper surface. The system's environment allows carbon atoms to dissociate and rearrange.

Ensuring Structural Continuity

By maintaining a stable environment, the APCVD system promotes epitaxial growth.

This means the new carbon layer aligns with the crystalline structure of the layer or substrate beneath it. This controlled alignment is what allows the system to produce "single-crystal" graphene, which is far superior in electrical quality to polycrystalline variations that have grain boundaries.

Understanding the Trade-offs

While APCVD systems are powerful, they rely on a delicate balance of variables. Understanding these sensitivities is crucial for consistent results.

Sensitivity to Gas Ratios

The difference between growing monolayer, bilayer, or multilayer graphene often comes down to minute adjustments in the methane-to-hydrogen ratio.

If the system fails to maintain precise flow control, the carbon supply may become too high (leading to thick graphite) or too low (resulting in discontinuous islands of graphene).

Contamination Risks

Although the growth happens at atmospheric pressure, the integrity of the environment is paramount.

Any ingress of oxygen or water vapor can ruin the crystallization process. Therefore, while it is an "atmospheric" system, it requires rigorous purging mechanisms to ensure the reaction chamber remains chemically inert during the high-temperature phase.

Making the Right Choice for Your Goal

When utilizing an APCVD system for graphene synthesis, your operational focus should shift based on your desired material outcome.

- If your primary focus is single-crystal quality: Prioritize the stability of the 1050 °C temperature zone to ensure the carbon atoms have sufficient energy to rearrange into a defect-free lattice.

- If your primary focus is strictly bilayer control: Focus entirely on the precision of the methane and hydrogen flow controllers, as the ratio of these gases dictates the self-limiting growth mechanism that stops at the second layer.

Success in APCVD synthesis is less about the equipment itself and more about the precise calibration of the thermodynamic environment it creates.

Summary Table:

| Parameter | Role in APCVD Synthesis |

|---|---|

| Furnace Temp | Maintains ~1050°C for precise carbon precursor decomposition |

| Gas Source | Methane ($CH_4$) provides the carbon atoms for lattice growth |

| Carrier Gases | Argon and Hydrogen ($H_2$) regulate reaction rate and layer count |

| Reactor Type | Quartz tube for inert, high-temperature catalytic reactions |

| Substrate | Copper foil acts as the catalyst for epitaxial alignment |

Elevate Your Graphene Research with KINTEK

Precise thermodynamic control is the difference between defect-ridden graphite and high-quality single-crystal bilayer graphene. KINTEK provides industry-leading CVD systems, Tube furnaces, and Vacuum solutions designed specifically for the rigorous demands of 1050°C material synthesis.

Backed by expert R&D and precision manufacturing, our systems are fully customizable to meet your unique gas flow and temperature stability needs. Contact us today to optimize your lab's synthesis capabilities.

Visual Guide

References

- Yung‐Chang Lin, Kazu Suenaga. Alkali metal bilayer intercalation in graphene. DOI: 10.1038/s41467-023-44602-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the two main types of CVD reactors? Choose the Right System for Your Lab

- How is gas flow controlled in CVD systems? Master Precise Gas Delivery for Superior Thin Films

- What are the different types of CVD furnaces? Choose the Right One for Your Lab

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- What is the mechanism of CVD reaction? Master the Steps from Gas to Thin Film

- What are some common applications of Chemical Vapor Deposition? Unlock High-Performance Thin Films for Your Industry

- How is CVD used in electronics manufacturing? Build High-Purity, Uniform Layers for Advanced Electronics

- What are the advantages and disadvantages of physical Vapour deposition? A Guide to High-Performance Thin Films