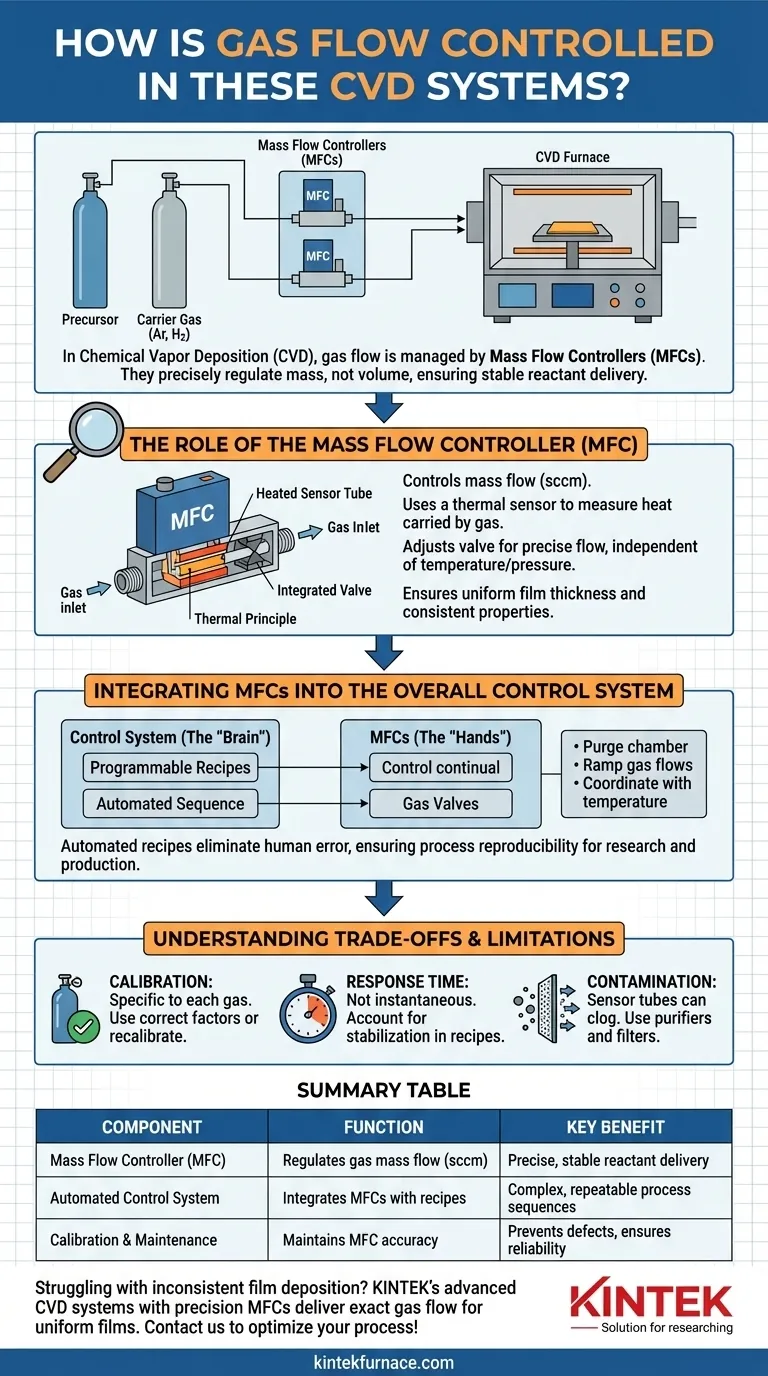

In a Chemical Vapor Deposition (CVD) system, gas flow is precisely managed by components called Mass Flow Controllers (MFCs). These devices are responsible for accurately measuring and regulating the amount of each precursor and carrier gas, such as Argon (Ar) and Hydrogen (H2), entering the furnace. The MFCs are a critical part of a larger automated control system that ensures the entire process is precise and repeatable.

The core challenge in CVD is not just delivering gases, but delivering a precise and stable number of reactant molecules to the substrate over time. Mass Flow Controllers are the standard solution because they control the mass of the gas—not just its volume—making the process immune to fluctuations in ambient temperature and pressure.

The Role of the Mass Flow Controller (MFC)

At the heart of gas control in any modern CVD system is the MFC. Understanding how it operates reveals why it is so essential for creating high-quality, uniform thin films.

What an MFC Actually Controls

The standard unit for gas flow in these systems is sccm, or Standard Cubic Centimeters per Minute. This is a unit of mass flow, not volumetric flow.

It represents a flow rate that has been normalized to a standard temperature (0°C) and pressure (1 atm). This ensures that a setpoint of "100 sccm" delivers the exact same number of gas molecules every time, regardless of the actual conditions in the lab.

How an MFC Works

An MFC typically operates on a thermal principle. A small, heated sensor tube inside the device measures how much heat is carried away by the flowing gas.

A higher flow rate removes more heat, creating a larger temperature difference across the sensor. This thermal measurement is converted into a precise mass flow reading. The controller then compares this reading to the user's setpoint and automatically adjusts an integrated valve to maintain the desired flow rate.

Why This Precision Matters for CVD

The rate of chemical reactions and subsequent film growth is directly dependent on the concentration of precursor molecules at the substrate surface.

By using MFCs to guarantee a stable and predictable flow of reactants, engineers can ensure that the resulting film has a uniform thickness and consistent material properties across the entire substrate.

Integrating MFCs into the Overall Control System

An MFC is a powerful component, but its true value is realized when it is part of a larger, programmable system.

From Component to System

The MFCs are the "hands" that control the gas valves, but the furnace's advanced control system is the "brain." A researcher or operator defines a process "recipe" within the system's software.

This recipe dictates the setpoints for each MFC at every step of the process, creating a fully automated and timed sequence of events.

The Power of Automated Recipes

This integration allows for complex process flows. For example, a recipe can automatically:

- Purge the chamber with an inert gas like Argon.

- Ramp up the flow of a reactant gas like Hydrogen.

- Hold gas flows steady during deposition.

- Coordinate these gas flow changes with specific temperature ramps in the furnace.

Ensuring Process Reproducibility

Automating the gas delivery eliminates the variability and human error associated with manual valve adjustments. This ensures that a process run today will have the identical gas flow profile as one run months later, which is fundamental for both scientific research and industrial production.

Understanding the Trade-offs and Limitations

While essential, MFCs are not infallible. Understanding their operational constraints is key to maintaining a reliable CVD process.

Calibration is Non-Negotiable

An MFC is factory-calibrated for a specific gas. Its thermal properties are unique; for example, Hydrogen carries away heat very differently than Argon.

Using an MFC with a gas it wasn't calibrated for will result in an inaccurate flow rate. Recalibration or the application of a known "gas correction factor" is required for accurate operation with different gases.

Response Time and Stability

MFCs do not change flow rates instantaneously. They have a specified response time (often a few seconds) to reach a new setpoint and stabilize. This must be accounted for in recipes that require very rapid gas switching.

Susceptibility to Contamination

The small sensor tubes and valve orifices within an MFC can become clogged or coated by contaminants or byproducts from the reaction. This will degrade accuracy and eventually cause failure. Upstream gas purifiers and filters are critical for ensuring the long-term reliability of the MFCs.

Making the Right Choice for Your Goal

Properly managing your gas delivery system is crucial for achieving your desired outcome. Your focus should adapt based on your primary objective.

- If your primary focus is research and development: Leverage the programmability of the control system to create complex recipes that carefully correlate gas flow changes with temperature to explore new material properties.

- If your primary focus is production consistency: Implement a rigorous calibration and preventative maintenance schedule for your MFCs to guarantee process stability and yield over the long term.

- If your primary focus is troubleshooting film defects: Always verify your MFC readbacks and calibration status first, as incorrect gas ratios are one of the most common sources of deposition problems.

Mastering your gas delivery system is the first step toward complete control over your material synthesis process.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Mass Flow Controller (MFC) | Measures and regulates gas mass flow in sccm | Ensures precise, stable reactant delivery |

| Automated Control System | Integrates MFCs with programmable recipes | Enables complex, repeatable process sequences |

| Calibration & Maintenance | Maintains MFC accuracy for specific gases | Prevents film defects and ensures long-term reliability |

Struggling with inconsistent film deposition in your lab? KINTEK's advanced high-temperature furnace solutions, including CVD/PECVD Systems, are engineered with precision Mass Flow Controllers and deep customization capabilities to deliver exact gas flow control for uniform thin films. Whether you're in R&D or production, our expertise ensures reliable, repeatable results tailored to your unique needs. Contact us today to optimize your CVD process and achieve superior material synthesis!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment