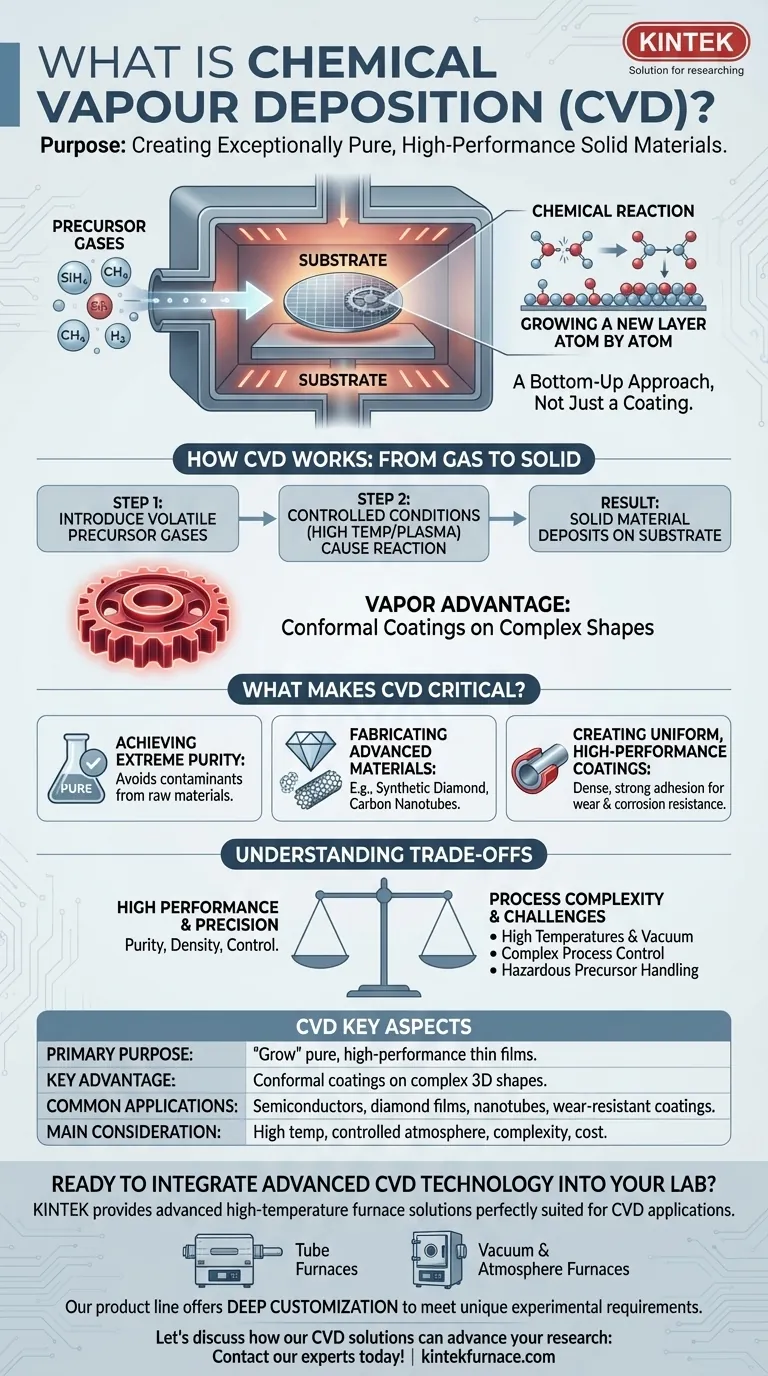

At its core, the purpose of Chemical Vapor Deposition (CVD) is to create exceptionally pure, high-performance solid materials, typically as a thin film, on a surface. It is not a coating process in the traditional sense, but rather a method for "growing" a new layer of material directly onto a substrate from chemical precursors in a gaseous state.

Think of CVD not as painting a surface, but as constructing a new material layer, atom by atom, from a vapor. This bottom-up approach is what enables the creation of advanced materials, like synthetic diamond films and carbon nanotubes, with properties that are often impossible to achieve with bulk materials.

How CVD Works: From Gas to Solid

CVD is a highly controlled manufacturing process that transforms gaseous molecules into a solid film on a substrate. This transformation is driven by a chemical reaction, not a physical one.

The Two-Step Principle

The entire process can be broken down into two fundamental steps. First, one or more volatile precursor gases are introduced into a reaction chamber. Second, conditions in the chamber (such as high temperature or plasma) cause the gases to react or decompose, leading to the formation of a solid material that deposits onto a waiting substrate.

The Role of the Substrate

The substrate is the workpiece or material upon which the new film is grown. It provides the surface for the chemical reaction to take place and for the new material to bond to. The choice of substrate is critical, as it must be able to withstand the process conditions.

Why "Vapor" Is the Key

Using a gas or vapor as the transport medium is essential to CVD's effectiveness. Gaseous molecules can flow into and around complex, three-dimensional shapes, ensuring the resulting film is conformal—meaning it has a uniform thickness across the entire surface, even in trenches or on sharp corners.

What Makes CVD a Critical Process?

CVD is employed when the desired material properties—such as purity, density, or crystal structure—are paramount. It offers a level of control that most other deposition techniques cannot match.

Achieving Extreme Purity

Because the precursor materials are highly purified gases, the resulting deposited film is also exceptionally pure. This process avoids the contaminants and impurities that are often present in the raw materials used for melting or sputtering processes.

Fabricating Advanced Materials

CVD is a cornerstone for producing materials that are difficult or impossible to make otherwise. As noted in the production of diamond films, CVD can precisely control the crystalline structure, creating everything from nanocrystalline to single-crystal diamond layers. It is also a primary method for growing carbon nanotubes and nanowires.

Creating Uniform, High-Performance Coatings

The films produced by CVD are typically very dense and have strong adhesion to the substrate. This makes them ideal for protective applications, such as creating wear-resistant or corrosion-resistant surfaces on cutting tools and industrial components.

Understanding the Trade-offs

While powerful, CVD is not the solution for every application. Its precision comes with specific challenges and limitations.

High Temperatures and Vacuum

Many CVD processes require very high temperatures to initiate the chemical reaction, which limits the types of substrate materials that can be used. The process is also typically performed under vacuum or in a highly controlled atmosphere, adding to equipment complexity and cost.

Process Complexity

Developing a stable and repeatable CVD process can be complex. Factors like gas flow rates, temperature, pressure, and chamber geometry must be precisely controlled to achieve the desired film quality.

Handling of Precursor Gases

The chemical precursors used in CVD can be toxic, flammable, or corrosive. This necessitates sophisticated safety systems and handling protocols, which contribute to the overall operational cost.

When to Consider CVD for Your Project

Choosing a deposition method depends entirely on your end goal, balancing performance requirements against cost and complexity.

- If your primary focus is creating materials with the highest possible purity and performance: CVD is the definitive process for applications like advanced semiconductors, high-efficiency solar cells, or synthetic diamond coatings.

- If your primary focus is coating complex 3D shapes with a perfectly uniform layer: CVD's ability to create conformal films is a significant advantage over line-of-sight methods like sputtering or evaporation.

- If your primary focus is a simple, low-cost protective layer on a flat surface: Simpler methods like electroplating, painting, or physical vapor deposition (PVD) may be more practical and cost-effective.

Ultimately, Chemical Vapor Deposition is the foundational technology for building the high-performance materials that define modern electronics and advanced engineering.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Purpose | To "grow" exceptionally pure, high-performance solid materials as a thin film on a substrate. |

| Key Advantage | Creates conformal coatings with uniform thickness on complex 3D shapes. |

| Common Applications | Semiconductor manufacturing, synthetic diamond films, carbon nanotubes, wear-resistant coatings. |

| Main Consideration | Requires high temperatures and controlled atmospheres, adding to process complexity and cost. |

Ready to Integrate Advanced CVD Technology into Your Lab?

Chemical Vapor Deposition is the definitive process for creating materials with the highest purity and performance. Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions perfectly suited for CVD applications.

Our product line, including specialized Tube Furnaces and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements, whether you are developing semiconductors, growing carbon nanotubes, or creating protective coatings.

Let's discuss how our CVD solutions can advance your research: Contact our experts today to customize your solution!

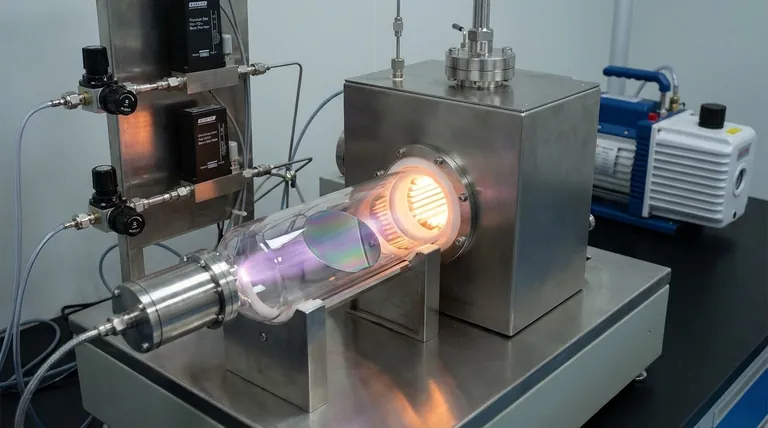

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why is a high-precision PECVD system required in ACSM? Enable Low-Temperature Atomic-Scale Manufacturing

- Why Use PECVD for Monolithic Integrated Chip Isolation Layers? Protect Your Thermal Budget with High-Quality SiO2

- What are the technical advantages of using a CVD system? Optimize Carbon Nanotube Growth for Thermal Conductivity

- What is the function of a PECVD system in the passivation of UMG silicon solar cells? Enhance Efficiency with Hydrogen

- What is the necessity of high-bias gas ion cleaning? Achieve Atomic-Level Coating Adhesion