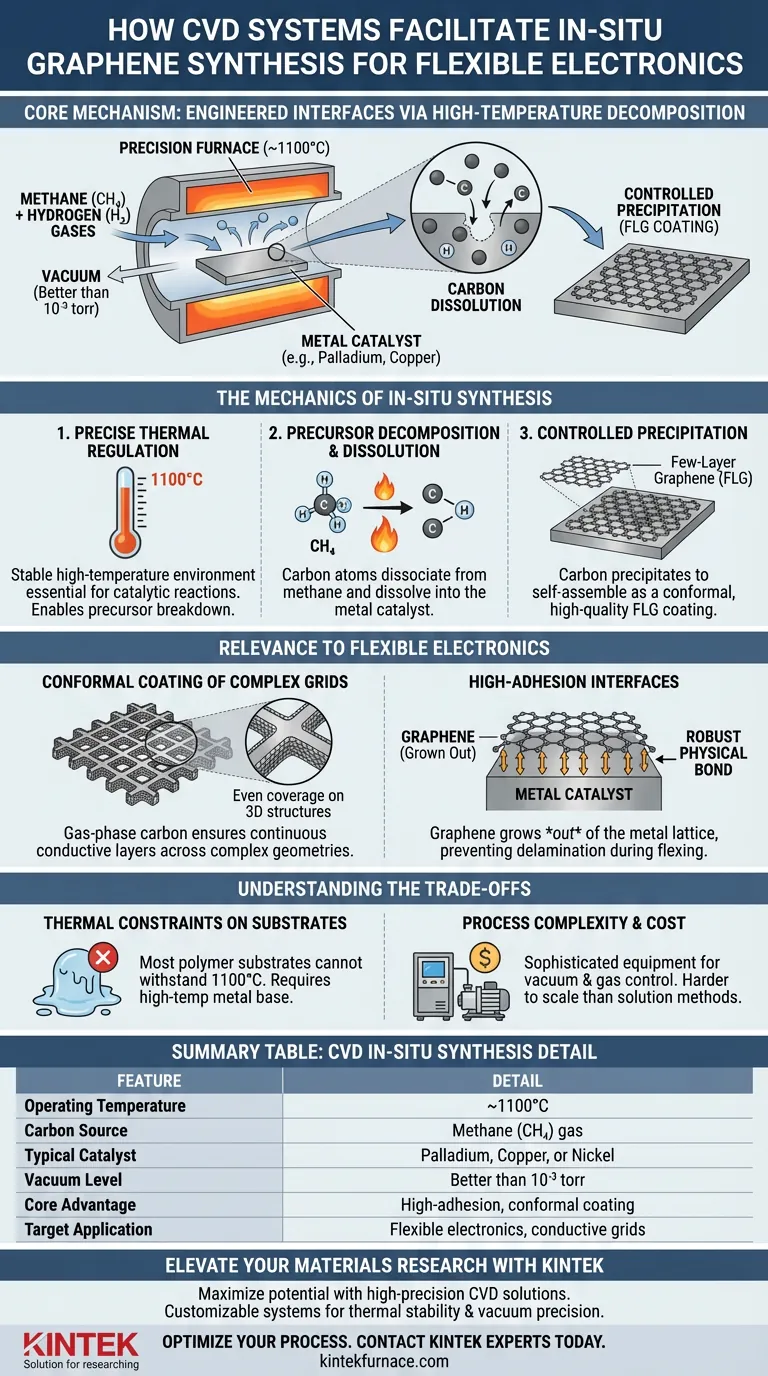

Chemical Vapor Deposition (CVD) systems facilitate in-situ graphene synthesis by maintaining a precisely controlled, high-temperature environment where carbon-rich gases decompose and reassemble directly onto a metal substrate. Specifically for flexible electronics, the system operates at temperatures around 1100°C to dissolve carbon atoms from methane into a metal catalyst, such as palladium, causing them to precipitate as a conformal, high-quality few-layer graphene (FLG) coating. This direct growth mechanism ensures a robust physical bond between the graphene and the complex metal grid, which is critical for maintaining performance during mechanical flexing.

The core advantage of using a CVD system lies in its ability to engineer the interface between the metal and the graphene. By growing graphene directly on the catalyst rather than transferring it, the system creates a high-strength, high-adhesion bond that prevents delamination in flexible applications.

The Mechanics of In-Situ Synthesis

Precise Thermal Regulation

The CVD system acts as a high-precision furnace, maintaining a stable thermodynamic environment essential for catalytic reactions. For the synthesis described, the system holds the process temperature at approximately 1100°C.

This elevated temperature is critical because it allows the metal catalyst (such as palladium or copper) to facilitate the breakdown of precursor gases. Without this thermal energy, the carbon atoms cannot properly dissociate or rearrange into the crystalline lattice required for high-quality graphene.

Precursor Decomposition and Dissolution

The system introduces a carbon source, typically methane gas, into the reaction chamber alongside carrier gases like hydrogen. Under the high heat and vacuum conditions (often better than $10^{-3}$ torr), the methane decomposes, releasing carbon atoms.

Rather than simply piling up on the surface, these carbon atoms dissolve into the metal catalyst. The CVD system controls this saturation point carefully; once the metal is saturated or chemically triggered, the carbon precipitates back out to the surface.

Controlled Precipitation

As the carbon precipitates, it self-assembles into layers of graphene. The CVD system regulates this growth through gas flow ratios and cooling rates to produce few-layer graphene (FLG).

This precipitation process is "in-situ," meaning the graphene forms directly on the final structure. This ensures the material covers the substrate conformally, replicating the underlying texture of the metal grid.

Relevance to Flexible Electronics

Conformal Coating of Complex Grids

Flexible electronics often rely on intricate metal grids to maintain conductivity while bending. A CVD system allows the graphene to coat these complex geometries evenly.

Because the synthesis is gas-phase based, the carbon atoms can penetrate and coat three-dimensional structures that physical deposition methods might miss. This results in a continuous conductive layer across the entire device.

High-Adhesion Interfaces

The durability of a flexible device depends on the strength of the bond between the conductor (metal) and the active material (graphene). The in-situ CVD process creates a high-strength interface.

Because the graphene grows out of the metal lattice during precipitation, the adhesion is significantly stronger than if a pre-made graphene sheet were simply pressed onto the metal. This prevents the graphene from peeling off when the device is bent or twisted.

Understanding the Trade-offs

Thermal Constraints on Substrates

The primary limitation of this specific CVD process is the 1100°C operating temperature. Most flexible polymer substrates (like plastic or rubber) cannot withstand this heat and would melt instantly.

Therefore, the graphene must be synthesized on a metal catalyst first. This restricts the types of substrates you can use initially, requiring either a transfer process later or the use of high-temperature-resistant metal foils as the base for the flexible electronics.

Process Complexity and Cost

Achieving the necessary vacuum levels and precise gas ratios requires sophisticated, expensive equipment. The system must manage the continuous removal of volatile by-products to prevent contamination.

Deviations in gas flow or temperature can lead to defects in the graphene lattice. This makes the process harder to scale for mass production compared to lower-quality solution-based methods.

Making the Right Choice for Your Goal

To leverage CVD synthesis effectively for your specific project, consider these strategic priorities:

- If your primary focus is mechanical durability: Prioritize the in-situ growth on palladium or copper to ensure a high-adhesion interface that withstands repeated flexing without delamination.

- If your primary focus is material quality: Ensure your system maintains a strict vacuum (better than $10^{-3}$ torr) and precise hydrogen-to-methane ratios to guarantee high crystallinity and continuity.

Ultimately, the CVD system is not just a coating tool, but an interface engineering platform that defines the structural integrity of your flexible electronic devices.

Summary Table:

| Feature | CVD In-Situ Synthesis Detail |

|---|---|

| Operating Temperature | Approximately 1100°C |

| Carbon Source | Methane (CH4) gas |

| Typical Catalyst | Palladium, Copper, or Nickel |

| Vacuum Level | Better than 10⁻³ torr |

| Core Advantage | High-adhesion, conformal coating on complex geometries |

| Target Application | Flexible electronics and durable conductive grids |

Elevate Your Materials Research with KINTEK

Maximize the potential of your flexible electronics with high-precision CVD solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique in-situ synthesis requirements. Our systems provide the thermal stability and vacuum precision necessary to engineer superior interfaces for high-growth applications.

Ready to optimize your synthesis process? Contact our technical experts today to find the perfect furnace for your laboratory needs.

Visual Guide

References

- Kaihao Zhang, Sameh Tawfick. Ultrathin damage-tolerant flexible metal interconnects reinforced by in-situ graphene synthesis. DOI: 10.1038/s41528-024-00300-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What role does a Chemical Vapor Deposition (CVD) system play in the synthesis of three-dimensional graphene (3DG)?

- Why is LPCVD equipment required for doped polysilicon layers? Key for Dense, High-Performance Passivated Contacts

- Why is CVD important in the fabrication of CMOS devices? Essential for Precise, Conformal Film Deposition

- What are the advantages of using a CVD system? Achieve Precision and Uniformity for Complex Thin Films

- MOCVD vs. PAMBE in beta-Ga2O3 Doping: Which System Is Best for Your Research?

- What types of materials can be produced using CVD? Unlock Versatile Thin Films and Advanced Materials

- What is the role of the pyrolysis chamber in the CVD process? Essential for Precursor Activation in Parylene Deposition

- What are some common applications of CVD in the semiconductor industry? Essential for Thin Film Deposition in Microchips