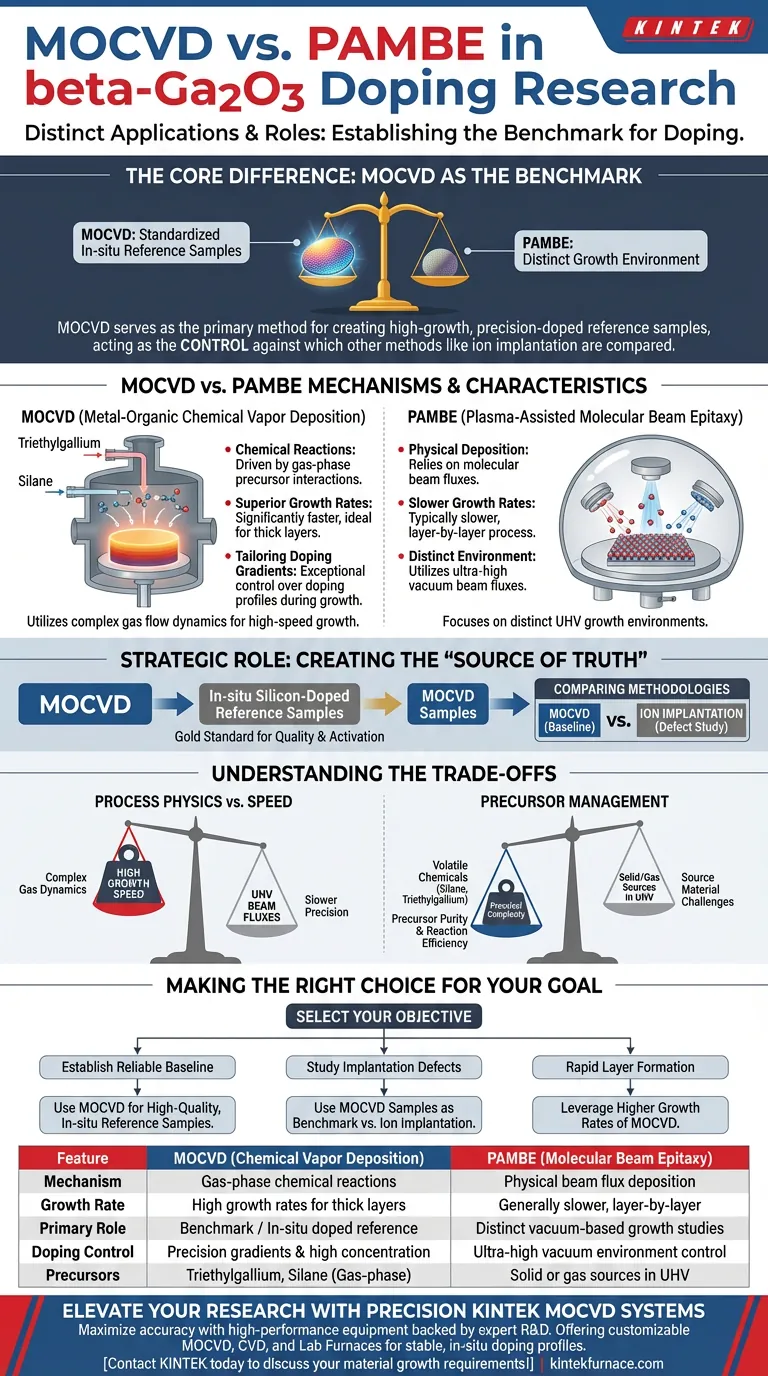

In the realm of beta-Ga2O3 doping research, Metal-Organic Chemical Vapor Deposition (MOCVD) distinguishes itself from Plasma-Assisted Molecular Beam Epitaxy (PAMBE) by serving as the primary method for creating standardized, in-situ silicon-doped reference samples. While PAMBE is often utilized for its distinct growth environment, MOCVD leverages the chemical reaction of gas-phase precursors to achieve higher growth rates and create specific doping gradients, making it the essential tool for benchmarking doping techniques.

MOCVD acts as the "control" method in doping studies, providing high-growth-rate, precision-doped reference samples that allow researchers to accurately compare the effects of ion implantation against stable, in-situ doping profiles.

The Mechanics of MOCVD Application

Driven by Chemical Reactions

Unlike the physical deposition processes often associated with molecular beam methods, MOCVD relies on chemical interactions.

It utilizes gas-phase precursors, specifically triethylgallium and silane, which react within the chamber to deposit the material.

Superior Growth Rates

A defining characteristic of MOCVD in this context is its efficiency.

The chemical nature of the precursor reaction allows for significantly higher growth rates compared to the typically slower deposition rates found in PAMBE systems.

Tailoring Doping Gradients

MOCVD offers exceptional control over the doping profile during the growth phase.

Researchers use this system to engineer specific doping concentration gradients, a capability that is critical for creating complex reference structures that mimic desired device behaviors.

The Strategic Role: Benchmarking and Reference

Creating the "Source of Truth"

The primary application of MOCVD in this field is to establish a baseline.

It is used to prepare in-situ silicon-doped reference samples, which serve as the gold standard for material quality and dopant activation.

Comparing Doping Methodologies

MOCVD samples provide the necessary data to evaluate other doping techniques.

By comparing MOCVD-grown samples against samples doped via ion implantation, researchers can isolate and study the specific differences and defects introduced by the implantation process.

Understanding the Trade-offs

Process Physics vs. Speed

While MOCVD offers speed, it is a fundamentally different process than PAMBE.

The higher growth rates of MOCVD are advantageous for creating thick reference layers, but this relies on complex gas flow dynamics rather than the ultra-high vacuum beam fluxes used in PAMBE.

Precursor Management

MOCVD requires the precise management of volatile chemicals like silane and triethylgallium.

This introduces a layer of chemical complexity regarding precursor purity and reaction efficiency that is distinct from the source material challenges found in PAMBE.

Making the Right Choice for Your Goal

To maximize the effectiveness of your beta-Ga2O3 research, select the system that aligns with your specific objective:

- If your primary focus is establishing a reliable baseline: Use MOCVD to create high-quality, in-situ silicon-doped reference samples.

- If your primary focus is studying implantation defects: Use MOCVD samples as the benchmark to contrast against the results of post-growth ion implantation.

- If your primary focus is rapid layer formation: Leverage the higher growth rates of MOCVD to fabricate necessary test structures efficiently.

Success in beta-Ga2O3 doping research relies on using MOCVD not just for growth, but as the calibration standard against which all other doping methods are measured.

Summary Table:

| Feature | MOCVD (Chemical Vapor Deposition) | PAMBE (Molecular Beam Epitaxy) |

|---|---|---|

| Mechanism | Gas-phase chemical reactions | Physical beam flux deposition |

| Growth Rate | High growth rates for thick layers | Generally slower, layer-by-layer |

| Primary Role | Benchmark / In-situ doped reference | Distinct vacuum-based growth studies |

| Doping Control | Precision gradients & high concentration | Ultra-high vacuum environment control |

| Precursors | Triethylgallium, Silane (Gas-phase) | Solid or gas sources in UHV |

Elevate Your Research with Precision MOCVD Systems

Maximize the accuracy of your beta-Ga2O3 doping studies with high-performance equipment. Backed by expert R&D and manufacturing, KINTEK offers cutting-edge MOCVD, CVD systems, and lab high-temp furnaces designed to deliver the stable, in-situ doping profiles your benchmarking requires.

Whether you need to engineer specific doping gradients or achieve superior growth rates, our systems are fully customizable to meet your unique research needs.

Contact KINTEK today to discuss your material growth requirements!

Visual Guide

References

- Katie R. Gann, Michael O. Thompson. Silicon implantation and annealing in <i>β</i>-Ga2O3: Role of ambient, temperature, and time. DOI: 10.1063/5.0184946

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the characteristics and uses of diamond-like carbon (DLC) coatings? Enhance Durability and Efficiency in Your Applications

- What is the function of high-purity Argon (Ar) gas during CVD? Optimize Your Thin Film Uniformity and Purity

- What is the role of a Chemical Vapor Deposition (CVD) system in the preparation of h-BN films? Precision & Scalability

- What is the high-temperature capability of specialized CVD furnaces? Achieve Up to 1950°C for Advanced Materials

- Why is precise control of carrier gas flow rates critical for TB-MoS2 yield? Master Kinetic Growth in CVD Systems

- What is the purpose of the sliding furnace mechanism? Achieve Rapid Thermal Quenching for Metastable Materials

- What is the purpose of using a mechanical vacuum pump for CVD MoS2 preparation? Ensure High-Purity Material Synthesis

- What is chemical vapor deposition (CVD) and its primary industrial application? Unlock Precision Thin Films for Electronics