Precise control of carrier gas flow rates is the determining factor in managing the kinetic energy environment within a Chemical Vapor Deposition (CVD) system. For twisted bilayer molybdenum disulfide (TB-MoS2), the flow rate directly influences turbulence and molecular collision frequency, creating the specific energy conditions required to nucleate twisted structures rather than standard aligned crystals.

Low carrier gas flow rates, when combined with spatial confinement, induce a backflow effect that significantly increases the collision energy between reactant molecules. This elevated energy state is the fundamental requirement for the high-yield nucleation and growth of twisted bilayer MoS2.

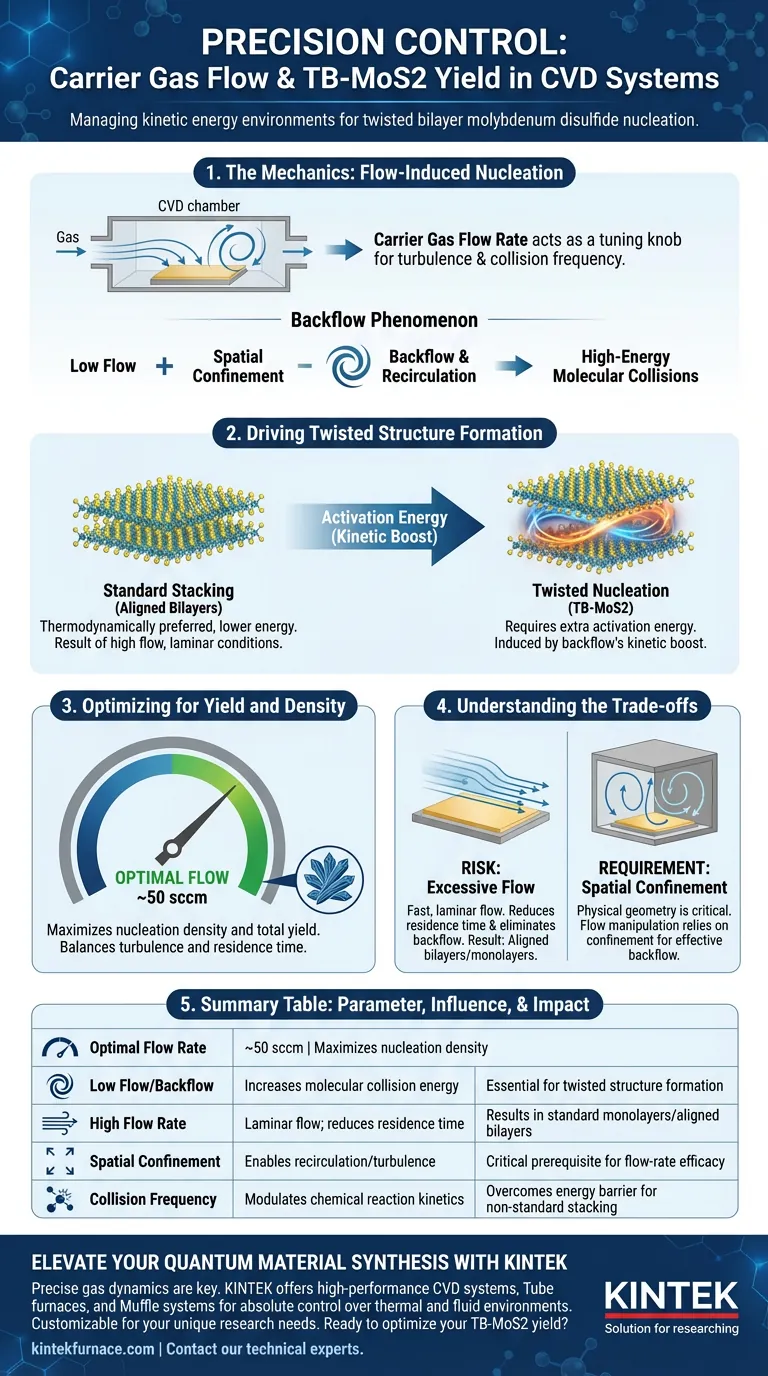

The Mechanics of Flow-Induced Nucleation

To understand why flow rate dictates yield, you must look beyond simple gas transport and examine the fluid dynamics occurring at the substrate level.

Regulating Turbulence and Collisions

The carrier gas flow rate acts as a tuning knob for the chaotic nature of the environment inside the CVD chamber. It determines the level of turbulence experienced by the precursor molecules.

When the flow rate is modulated effectively, it alters the frequency at which precursor molecules collide with one another and with the substrate. This collision frequency is a critical variable in chemical reaction kinetics.

The Phenomenon of Backflow

The primary reference highlights a specific interaction between flow rate and "spatial confinement." Simply lowering the flow isn't enough; the geometry matters.

In a confined environment, a lower flow rate triggers backflow. This means the gas doesn't just pass over the substrate; it recirculates. This recirculation creates a dense, high-energy environment where reactants interact more vigorously.

Driving Twisted Structure Formation

Creating a "twisted" bilayer is energetically different from creating a standard, aligned bilayer. The flow rate provides the necessary energy to bridge this gap.

Overcoming the Energy Barrier

Standard stacking (Bernal stacking) is often the thermodynamically preferred, lower-energy state. To induce twisted nucleation, the system requires additional energy.

The backflow caused by lower flow rates increases the collision energy between molecules. This kinetic boost provides the activation energy necessary to promote twisted nucleation, pushing the system out of its default alignment and into the desired twisted configuration.

Optimizing for Yield and Density

Precision is key. The relationship between flow and yield is not linear; it is specific.

The reference data suggests that maintaining a flow rate of approximately 50 sccm is optimal. At this specific rate, the balance of turbulence and residence time maximizes both the yield (total amount) and the density of the TB-MoS2 crystals.

Understanding the Trade-offs

While low flow rates are beneficial for this specific application, they must be balanced carefully against process stability.

The Risk of Excessive Flow

If the carrier gas flow rate is too high, the flow becomes laminar and fast. This reduces the residence time of precursors and eliminates the backflow effect.

Without backflow, the collision energy drops. Consequently, the system lacks the energy required to nucleate twisted structures, likely resulting in standard monolayers or aligned bilayers instead.

The Necessity of Confinement

It is critical to note that flow rate manipulation relies on spatial confinement to be effective.

Lowering the flow rate in an open, unconfined setup may not generate the necessary backflow. The physical geometry of the setup and the flow rate are interdependent variables; one cannot be optimized without the other.

Making the Right Choice for Your Goal

Achieving high-yield TB-MoS2 requires shifting your focus from simple transport efficiency to kinetic energy management.

- If your primary focus is generating twisted structures: Prioritize a lower flow rate (around 50 sccm) to induce the necessary backflow and turbulence.

- If your primary focus is experimental setup: Ensure your CVD system utilizes a spatial confinement environment, as low flow rates alone may be insufficient to trigger high-energy collisions.

By treating the carrier gas flow not just as a transport medium, but as a source of kinetic energy, you can successfully engineering the growth of complex, twisted quantum materials.

Summary Table:

| Parameter | Influence on TB-MoS2 Growth | Impact on Yield |

|---|---|---|

| Optimal Flow Rate | ~50 sccm | Maximizes nucleation density |

| Low Flow/Backflow | Increases molecular collision energy | Essential for twisted structure formation |

| High Flow Rate | Laminar flow; reduces residence time | Results in standard monolayers/aligned bilayers |

| Spatial Confinement | Enables recirculation/turbulence | Critical prerequisite for flow-rate efficacy |

| Collision Frequency | Modulates chemical reaction kinetics | Overcomes energy barrier for non-standard stacking |

Elevate Your Quantum Material Synthesis with KINTEK

Precise gas dynamics are the difference between standard crystals and high-yield twisted bilayers. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance CVD systems, Tube furnaces, and Muffle systems designed to give you absolute control over your thermal and fluid environments.

Whether you need custom spatial confinement setups or precise mass flow control, our lab high-temp furnaces are fully customizable to meet your unique research needs.

Ready to optimize your TB-MoS2 yield? Contact our technical experts today to find the perfect solution for your laboratory.

Visual Guide

References

- Manzhang Xu, Wei Huang. Reconfiguring nucleation for CVD growth of twisted bilayer MoS2 with a wide range of twist angles. DOI: 10.1038/s41467-023-44598-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What roles do quartz boats and quartz tubes play in MoS2 CVD synthesis? Optimize Isotope-Engineered Monolayer Growth

- What are the advantages of CVD vs. powder methods for catalysts? Unlock binder-free, high-performance electrode growth.

- What are the different types of chemical vapour deposition? A Guide to Selecting the Right CVD Process

- What are the disadvantages of chemical Vapour deposition method? High Costs, Complexity & Material Limits

- What is the role of a vertical tube FCCVD system? Scalable High-Volume Synthesis of SWCNTs

- What is Chemical Vapor Deposition (CVD) and its role in electronics manufacturing? Unlock Precision in Semiconductor Fabrication

- What types of materials can be produced using CVD? Unlock Versatile Thin Films and Advanced Materials

- What are the technical advantages of using a vacuum thermal evaporation system? Precision in High-Purity Thin-Film Deposition