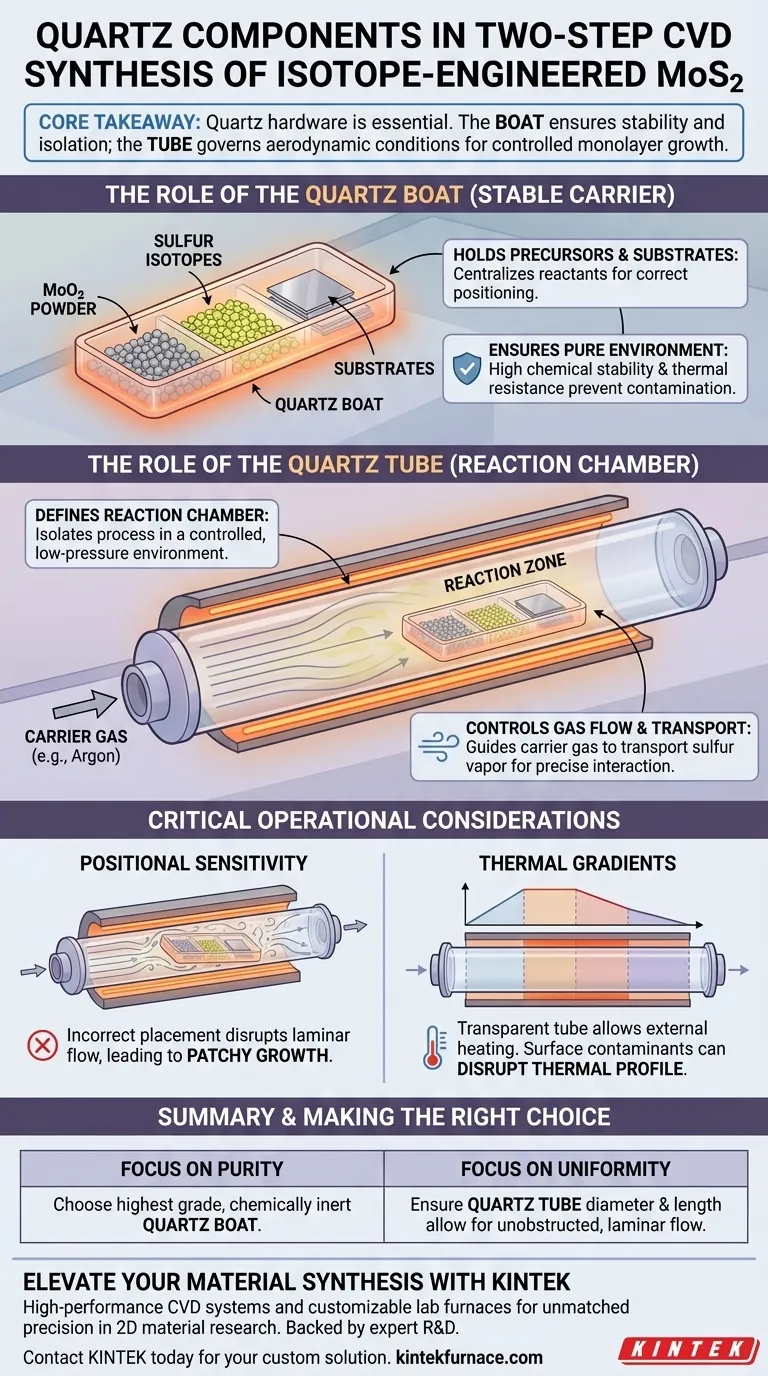

In the two-step chemical vapor deposition (CVD) synthesis of sulfur isotope-engineered molybdenum disulfide (MoS2), quartz components provide the essential infrastructure for controlling the reaction environment. The quartz boat acts as a stable carrier, holding the molybdenum dioxide (MoO2) powder, specific sulfur isotope elements, and the target substrates. The quartz tube serves as the primary reaction chamber, creating a sealed channel that guides carrier gases to transport sulfur vapor precisely to the reaction zone.

Core Takeaway The success of this synthesis relies on the distinct functions of the quartz hardware: the boat ensures the physical stability and isolation of high-purity precursors, while the tube governs the aerodynamic conditions necessary for controlled monolayer growth.

The Role of the Quartz Boat

Holding the Precursors and Substrates

In this specific CVD process, the quartz boat functions as the primary loading vessel. It physically contains the solid-state precursors required for the reaction, specifically molybdenum dioxide (MoO2) powder and high-purity sulfur isotope elements.

Additionally, the boat holds the substrates upon which the MoS2 monolayers will eventually grow. This centralization ensures that all reactants are positioned correctly relative to one another before the process begins.

Ensuring a Pure Reaction Environment

The material properties of the quartz boat are vital for isotope engineering. Because it acts as the direct contact point for the reactants, it must exhibit high chemical stability.

The boat resists degradation at the high temperatures required for CVD. This thermal resistance prevents the container itself from releasing impurities that could contaminate the sulfur isotopes or the growing MoS2 crystal lattice.

The Role of the Quartz Tube

Defining the Reaction Chamber

The quartz tube acts as the outer shell of the system, effectively serving as the reaction chamber. It isolates the process from the outside atmosphere, allowing for a controlled, low-pressure environment.

Controlling Gas Flow and Transport

The geometry of the quartz tube creates a specific flow channel for carrier gases, such as argon. This channel is critical for the "transport" phase of the synthesis.

As the sulfur isotopes vaporize, the quartz tube confines the argon flow, forcing it to carry the sulfur vapor directly into the reaction zone. This guided transport mechanism enables the precise interaction between sulfur and molybdenum necessary for the controlled growth of MoS2 monolayers.

Critical Operational Considerations

Positional Sensitivity

While the quartz tube provides the channel, the effectiveness of the gas flow depends heavily on the placement of the quartz boat within that tube.

If the boat is positioned incorrectly, it may disrupt the laminar flow of the carrier gas. This can lead to uneven distribution of sulfur vapor, resulting in patchy or incomplete MoS2 growth rather than uniform monolayers.

Thermal Gradients

The quartz tube allows for the establishment of temperature zones, but it does not generate heat itself.

The transparency and thermal properties of the tube allow external furnaces to heat the boat and precursors. However, the user must ensure the tube is clean and free of deposits, as surface contaminants can alter heat absorption and disrupt the precise thermal profile needed for the reaction.

Making the Right Choice for Your Goal

To maximize the quality of your sulfur isotope-engineered MoS2, focus on the specific function of each component:

- If your primary focus is Purity: Ensure your quartz boat is of the highest grade and chemically inert to prevent contamination of the sensitive sulfur isotopes.

- If your primary focus is Uniformity: Verify that the quartz tube diameter and length allow for unobstructed, laminar argon flow to transport vapor evenly across the substrate.

By ensuring the stability of the boat and the flow dynamics of the tube, you secure the foundation for high-quality monolayer synthesis.

Summary Table:

| Component | Primary Role | Key Function in CVD |

|---|---|---|

| Quartz Boat | Precursor Carrier | Securely holds MoO2, sulfur isotopes, and substrates; ensures chemical purity at high temps. |

| Quartz Tube | Reaction Chamber | Creates a sealed, low-pressure environment and guides carrier gas for precise vapor transport. |

| Carrier Gas | Transport Medium | (Typically Argon) Moves vaporized sulfur to the reaction zone for uniform monolayer deposition. |

Elevate Your Material Synthesis with KINTEK

Ready to achieve unmatched precision in your 2D material research? Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique experimental needs. Whether you require superior thermal stability for isotope engineering or optimized gas flow for monolayer growth, our lab high-temp furnaces provide the control you demand.

Contact KINTEK today to discuss your custom furnace solution and see how our expertise can drive your next breakthrough.

Visual Guide

References

- Vaibhav Varade, Jana Vejpravová. Sulfur isotope engineering in heterostructures of transition metal dichalcogenides. DOI: 10.1039/d4na00897a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does CVD demonstrate high versatility and material compatibility? Unlock Precision Coating Solutions

- How is argon used in Physical Vapor Deposition (PVD) processes? Enhance Coating Purity and Efficiency

- What are the advantages of using in-situ CVD for Ag-ZIF-8/Ni foam? Enhance Structural Stability & Uniformity

- In which fields is CVD commonly used? Essential Applications in Electronics, Coatings, and More

- What role does a Vertical Cold Wall MOCVD system play in WSe2 synthesis? Expert Insights on Epitaxial Growth

- What are the cons of the CVD process? High Costs, Safety Risks, and Production Limits

- What is the role of the gold (Au) catalyst layer in the VLS growth of ZnO nanowires? Master Precision Synthesis

- How do quartz tube dimensions influence MoS2 CVD synthesis? Optimize Flow for High-Quality Monolayers