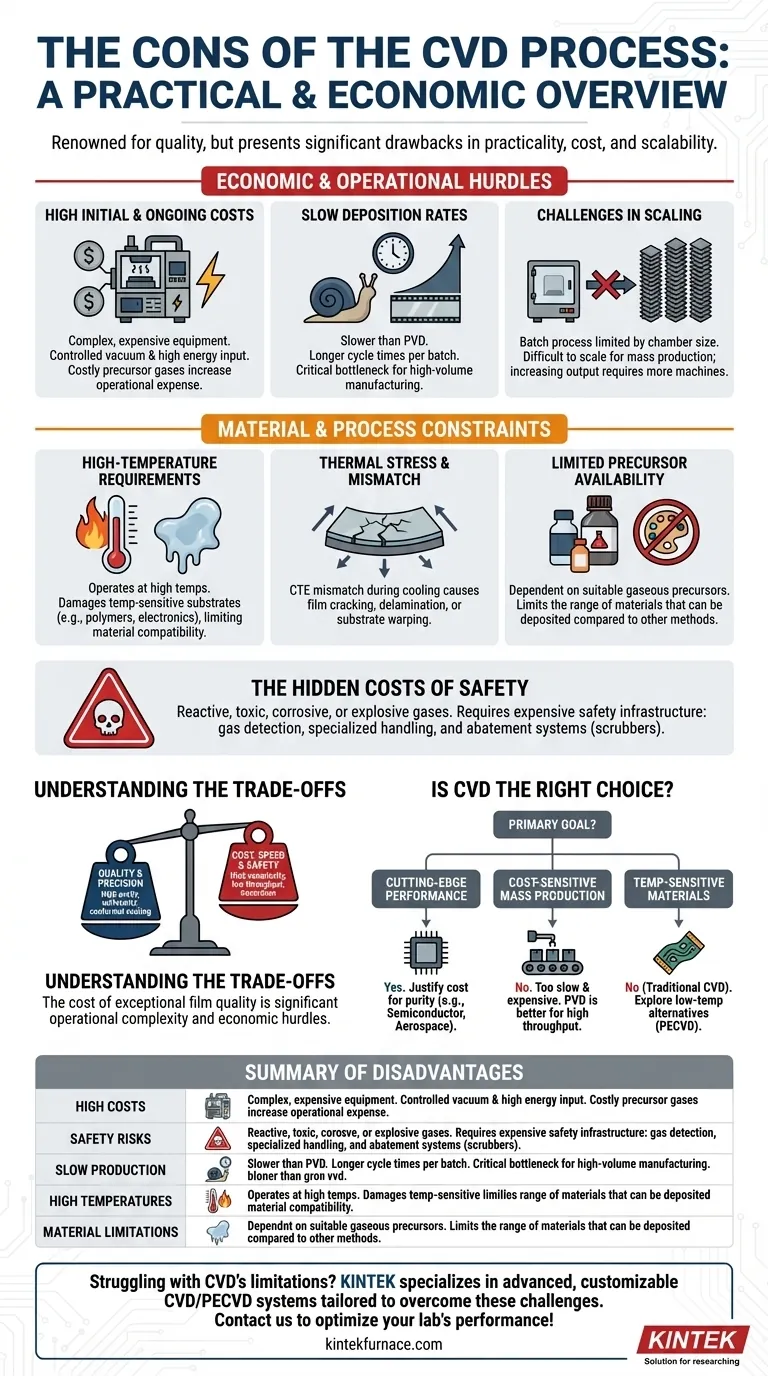

While renowned for producing high-quality thin films, the Chemical Vapor Deposition (CVD) process presents significant practical and economic drawbacks. The primary disadvantages are its high operational costs, the use of potentially toxic or explosive precursor materials, high-temperature requirements that can damage substrates, and inherent limitations in production speed and scalability. These factors make it a specialized process rather than a universally applicable one.

The fundamental challenge of CVD is a trade-off between precision and practicality. While it offers exceptional control over film quality and purity, this comes at the cost of significant operational complexity, safety considerations, and economic hurdles that make it unsuitable for many mass-production scenarios.

The Economic and Operational Hurdles

For many engineering projects, the viability of a process comes down to cost and throughput. CVD presents considerable challenges in both areas.

High Initial and Ongoing Costs

The equipment required for CVD is complex and expensive. It demands a highly controlled vacuum environment, precise gas flow controllers, and significant energy input, all of which contribute to a high capital investment. Furthermore, some precursor gases, particularly metal-organic compounds, are costly consumables that drive up the operational expense per run.

Slow Deposition Rates

Compared to other techniques like Physical Vapor Deposition (PVD), CVD typically has a slower rate of film growth. This directly translates to longer cycle times for each batch of parts. For high-volume manufacturing, this low throughput can become a critical bottleneck, increasing the cost-per-unit and extending lead times.

Challenges in Scaling Production

CVD is fundamentally a batch process limited by the physical size of the reaction chamber. This constraint makes it difficult to scale up for true mass production, as you can only coat as many parts as can fit in the chamber at one time. Increasing output often requires purchasing more machines rather than simply speeding up a single production line.

Material and Process Constraints

Beyond economics, the physics and chemistry of the CVD process itself impose several key limitations that can exclude it as an option for certain applications.

High-Temperature Requirements

Most traditional CVD processes operate at very high temperatures to provide the activation energy needed for the chemical reactions to occur on the substrate surface. This heat can easily damage or deform temperature-sensitive substrates like polymers, plastics, or certain electronic components, severely limiting material compatibility.

Thermal Stress and Mismatch

Even if a substrate can withstand the heat, a high-temperature process can induce significant stress. When the chamber cools, the newly deposited film and the underlying substrate contract at different rates (a difference in the Coefficient of Thermal Expansion). This mismatch can cause film cracking, delamination, or warping of the substrate.

Limited Precursor Availability

The CVD process is entirely dependent on the availability of suitable precursor chemicals that can be delivered in a gaseous state. Not all materials can be easily or economically converted into a stable, effective precursor gas, which limits the palette of materials that can be deposited compared to other methods like sputtering.

Understanding the Trade-offs

The disadvantages of CVD do not exist in a vacuum; they are the direct trade-offs for its primary benefits. Understanding this balance is key to making an informed decision.

Quality vs. Cost and Speed

The reason engineers tolerate the high cost and slow speed of CVD is its ability to produce exceptionally high-purity, uniform, and dense films. It offers precise control over film thickness and composition that is difficult to achieve with other methods. The process excels at coating complex 3D shapes conformally, something many line-of-sight deposition techniques cannot do.

The Hidden Costs of Safety

The reactive and often hazardous nature of CVD precursor gases and their byproducts cannot be overlooked. These substances can be toxic, corrosive, or even explosive. Managing this risk requires expensive safety infrastructure, including gas detection systems, specialized handling protocols, and abatement systems (scrubbers) to treat the exhaust. These are not optional expenses; they are critical safety and environmental requirements.

Is CVD the Right Choice for Your Application?

Choosing a deposition technology requires matching the process capabilities to your project's primary goal.

- If your primary focus is cutting-edge performance: The exceptional purity, uniformity, and material properties achievable with CVD often justify its high cost and complexity, especially in semiconductor, optics, and aerospace applications.

- If your primary focus is cost-sensitive mass production: The slow deposition rates, batch processing nature, and high operational costs of CVD make it a poor fit. Other methods like PVD are typically better suited for high throughput.

- If your primary focus is coating temperature-sensitive materials: Traditional high-temperature CVD is likely unsuitable. You must explore low-temperature alternatives (like PECVD) or entirely different deposition technologies.

Ultimately, understanding these limitations is the first step toward selecting the most effective and economical deposition technology for your specific engineering goals.

Summary Table:

| Disadvantage | Key Details |

|---|---|

| High Costs | Expensive equipment, costly precursor gases, and high energy consumption increase operational expenses. |

| Safety Risks | Use of toxic, corrosive, or explosive gases requires strict safety measures and infrastructure. |

| Slow Production | Low deposition rates and batch processing limit throughput and scalability for mass production. |

| High Temperatures | Can damage temperature-sensitive substrates and cause thermal stress or film delamination. |

| Material Limitations | Restricted by precursor availability, limiting the range of materials that can be deposited. |

Struggling with CVD's high costs and safety challenges? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD systems, tailored to overcome these limitations. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs, ensuring efficiency and reliability. Contact us today to discuss how our Muffle, Tube, Rotary, Vacuum, and Atmosphere Furnaces can optimize your lab's performance!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis