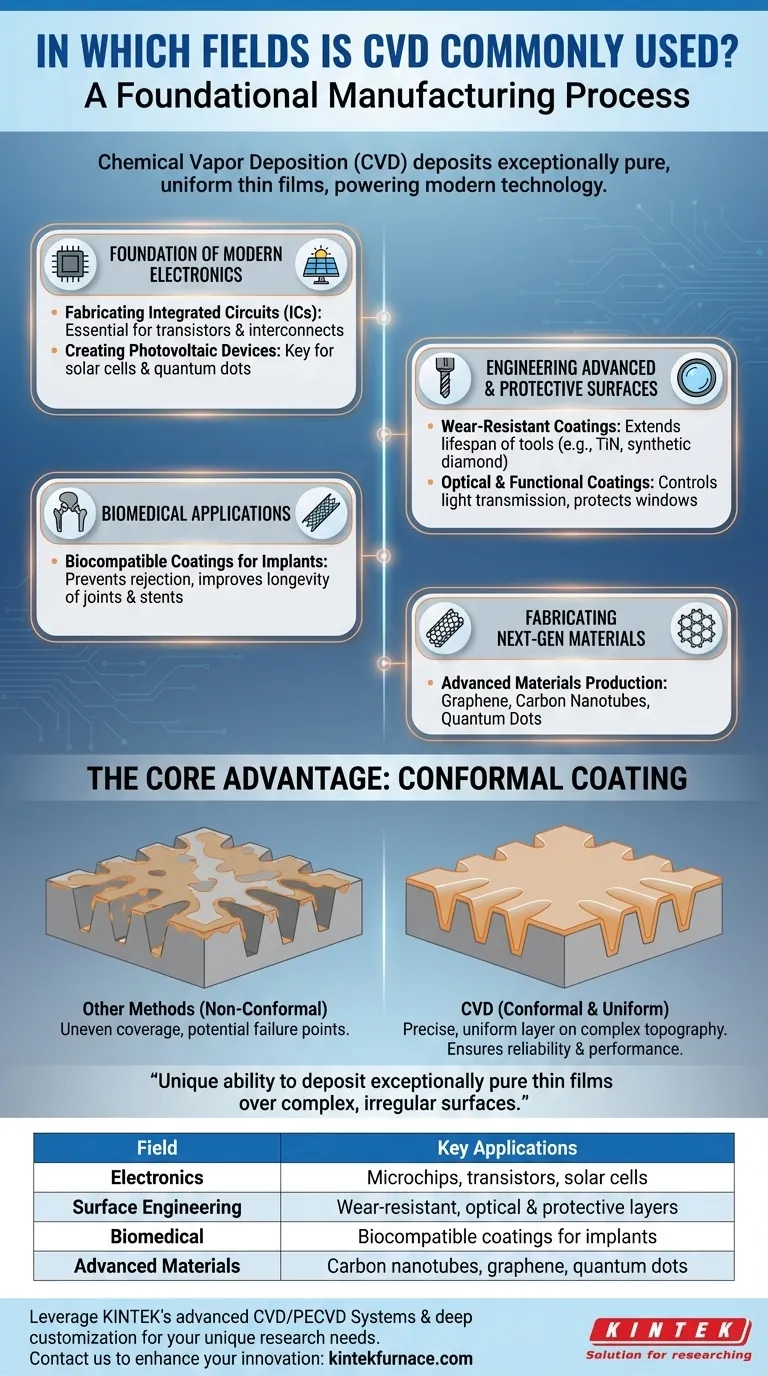

At its core, Chemical Vapor Deposition (CVD) is a foundational manufacturing process used across numerous high-technology fields. It is most commonly applied in the production of semiconductor devices, optical components, advanced materials like carbon nanotubes, and durable, functional coatings for industries ranging from aerospace to biomedical.

The widespread use of CVD is not just about the materials it can create, but how it creates them. Its unique ability to deposit exceptionally pure and uniform thin films over complex, irregular surfaces is what makes it an indispensable tool for modern technology.

The Foundation of Modern Electronics

CVD is not just a part of the electronics industry; it is the process upon which the entire digital world is built. Its precision at the atomic scale is essential for fabricating microchips.

Fabricating Integrated Circuits (ICs)

Nearly every component inside a microchip, from transistors to interconnects, is built using CVD. The process deposits the ultra-thin, alternating layers of semiconductor, insulating, and metallic materials that form the complex architecture of an integrated circuit.

Creating Photovoltaic Devices

CVD is a key technique for manufacturing solar cells. It is used to deposit the thin films of silicon or other photovoltaic materials (like quantum dots) that capture sunlight and convert it into electricity.

Engineering Advanced and Protective Surfaces

One of CVD's most powerful applications is surface modification, where it imparts new properties to a base material by adding a thin, high-performance layer.

Wear-Resistant Coatings

In demanding mechanical applications, CVD is used to deposit extremely hard coatings, such as titanium nitride or synthetic diamond films, onto cutting tools and engine components. This dramatically increases their lifespan and performance.

Optical and Functional Coatings

CVD creates thin films for optical devices, including anti-reflective coatings on lenses and protective layers on optical windows used in harsh environments. These coatings are precisely engineered to control how light is transmitted or reflected.

Biomedical Applications

For medical implants like artificial joints or stents, biocompatibility is critical. CVD is used to apply inert, biocompatible coatings that prevent rejection by the body and improve the device's longevity.

Understanding the Core Advantage: Conformal Coating

To grasp why CVD is so prevalent, you must understand its primary technical advantage over other deposition methods.

What is a Conformal Coating?

A conformal coating is a film that follows the exact topography of the substrate, covering every peak, valley, and crevice with a layer of uniform thickness. CVD excels at this because the chemical reaction happens everywhere on the surface at once.

Why It Matters

In microelectronics, incomplete coverage of a microscopic trench can cause a circuit to fail. On an aerospace turbine blade, an uneven coating can create a weak point. CVD's ability to create a perfect, conformal film on irregular shapes ensures reliability and performance where other techniques fall short.

How to Apply This Knowledge

Your interest in CVD's applications likely stems from a specific technical or industrial context.

- If your primary focus is electronics manufacturing: Recognize that CVD is the non-negotiable process for building the fundamental layers of virtually all semiconductor devices.

- If your primary focus is material engineering: View CVD as the premier tool for creating high-performance surfaces, enhancing properties like hardness, chemical resistance, or biocompatibility.

- If your primary focus is research and development: Understand that CVD is the gateway to fabricating next-generation materials like graphene, carbon nanotubes, and quantum dots.

Ultimately, understanding where CVD is used is to understand what drives innovation in a vast range of modern technological fields.

Summary Table:

| Field | Key Applications |

|---|---|

| Electronics | Fabrication of microchips, transistors, and solar cells |

| Surface Engineering | Wear-resistant coatings, optical films, and protective layers |

| Biomedical | Biocompatible coatings for implants like stents and joints |

| Advanced Materials | Production of carbon nanotubes, graphene, and quantum dots |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for applications in electronics, coatings, and materials science. Contact us today to enhance your innovation with tailored CVD solutions!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes