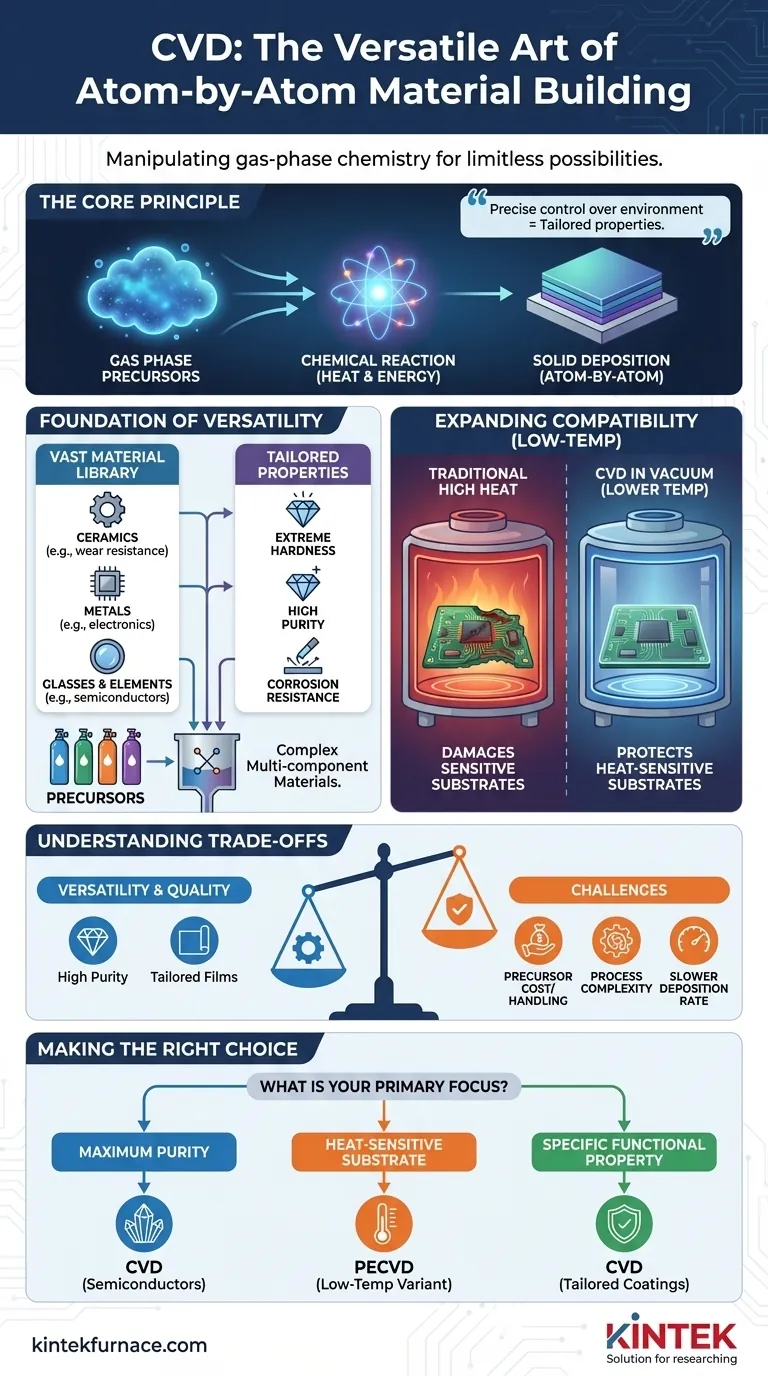

In essence, Chemical Vapor Deposition (CVD) achieves its high versatility by manipulating gas-phase chemistry to build solid materials atom by atom. This fundamental process allows it to deposit a vast range of materials—from pure metals to complex ceramics—onto many different surfaces. Furthermore, its ability to operate under vacuum conditions lowers the required reaction temperatures, making it compatible with heat-sensitive substrates that other processes would damage.

CVD’s versatility stems not just from the wide variety of materials it can create, but from its precise control over the deposition environment. By adjusting temperature, pressure, and precursor gases, engineers can tailor the final material's properties to solve a specific problem.

The Foundation of Versatility: Control Over Chemistry

The core strength of CVD lies in its transition from a gaseous state to a solid state. This gives it a level of control that is difficult to achieve with processes that start from a liquid or solid source.

The Core Deposition Mechanism

The CVD process introduces reactive gases, known as precursors, into a chamber containing the object to be coated, or the substrate. When these gases are heated, they undergo chemical reactions and decompose, depositing a thin, solid film onto the substrate's surface. By simply changing the precursor gases, you can fundamentally change the material being deposited.

A Vast Library of Materials

This gas-based approach unlocks an enormous catalog of potential materials. CVD is not limited to a single class of substance. It can be used to deposit:

- Ceramics (e.g., silicon nitride for wear resistance)

- Metals (e.g., tungsten for electronics)

- Glasses and pure elements (e.g., silicon for semiconductors)

This adaptability makes it a cornerstone technology in industries as diverse as aerospace and microelectronics.

Tailoring Properties at the Atomic Level

Versatility extends beyond just the type of material. By mixing multiple precursor gases or fine-tuning reaction conditions, you can synthesize complex, multi-component materials. This allows for the precise engineering of specific properties, such as extreme hardness, high purity, or superior corrosion resistance, directly into the deposited film.

Expanding Compatibility Through Process Conditions

CVD's compatibility with a wide range of substrate materials is directly tied to its ability to manipulate the physical environment of the reaction, particularly temperature and pressure.

The Role of Vacuum Operation

Many chemical reactions require significant heat to initiate. However, by performing the deposition inside a vacuum, the overall pressure in the chamber is drastically reduced. In this low-pressure environment, reactions can often proceed at significantly lower temperatures.

Protecting Heat-Sensitive Substrates

This ability to lower the process temperature is critical for material compatibility. It allows for the successful coating of substrates that cannot withstand high heat, such as certain polymers or assembled electronic components with low melting-point solder. Without this low-temperature capability, the substrate itself could be damaged or destroyed during the coating process.

Understanding the Trade-offs

While highly versatile, CVD is not a universal solution. Understanding its limitations is key to using it effectively.

Precursor Handling and Cost

The precursor gases required for CVD can be highly toxic, flammable, or expensive. Sourcing and safely handling the specific precursors needed for a novel material can present significant logistical and financial challenges.

Process Complexity

Achieving a high-quality, uniform coating requires precise control over gas flow, temperature, and pressure. Designing a reactor and optimizing a CVD process for a new application, especially for substrates with complex geometries, can be a time-consuming and complex engineering task.

Deposition Rate

Compared to some other coating methods like thermal spraying, CVD can be a relatively slow process. For applications requiring very thick coatings over large areas, the time required may make it impractical.

Making the Right Choice for Your Application

Ultimately, the decision to use CVD should be based on your project's specific technical requirements.

- If your primary focus is maximum purity and crystalline quality: CVD is an exceptional choice, as its chemical nature allows for building films with minimal contamination, crucial for semiconductors.

- If your primary focus is coating a heat-sensitive substrate: A low-temperature variant like Plasma-Enhanced CVD (PECVD) is the ideal approach to prevent damage to the underlying material.

- If your primary focus is achieving a specific functional property: CVD's ability to precisely control film composition makes it perfect for engineering coatings with tailored corrosion resistance, hardness, or optical characteristics.

By understanding the interplay between its chemical and physical principles, you can leverage CVD's remarkable versatility to solve a wide array of material engineering challenges.

Summary Table:

| Aspect | Key Features |

|---|---|

| Versatility | Deposits ceramics, metals, glasses; precise control via temperature, pressure, and precursors |

| Material Compatibility | Operates at lower temperatures under vacuum, protects heat-sensitive substrates |

| Applications | Semiconductors, wear-resistant coatings, electronics, aerospace components |

| Limitations | High precursor costs, process complexity, slower deposition rates |

Unlock the full potential of CVD for your laboratory with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and results. Contact us today to discuss how our tailored solutions can benefit your projects!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis

- What is the necessity of high-bias gas ion cleaning? Achieve Atomic-Level Coating Adhesion

- What gases are used in chemical vapor deposition? Master Precursor & Process Gases for Superior Films

- Why Use PECVD for Monolithic Integrated Chip Isolation Layers? Protect Your Thermal Budget with High-Quality SiO2

- Why is a high-precision PECVD system required in ACSM? Enable Low-Temperature Atomic-Scale Manufacturing