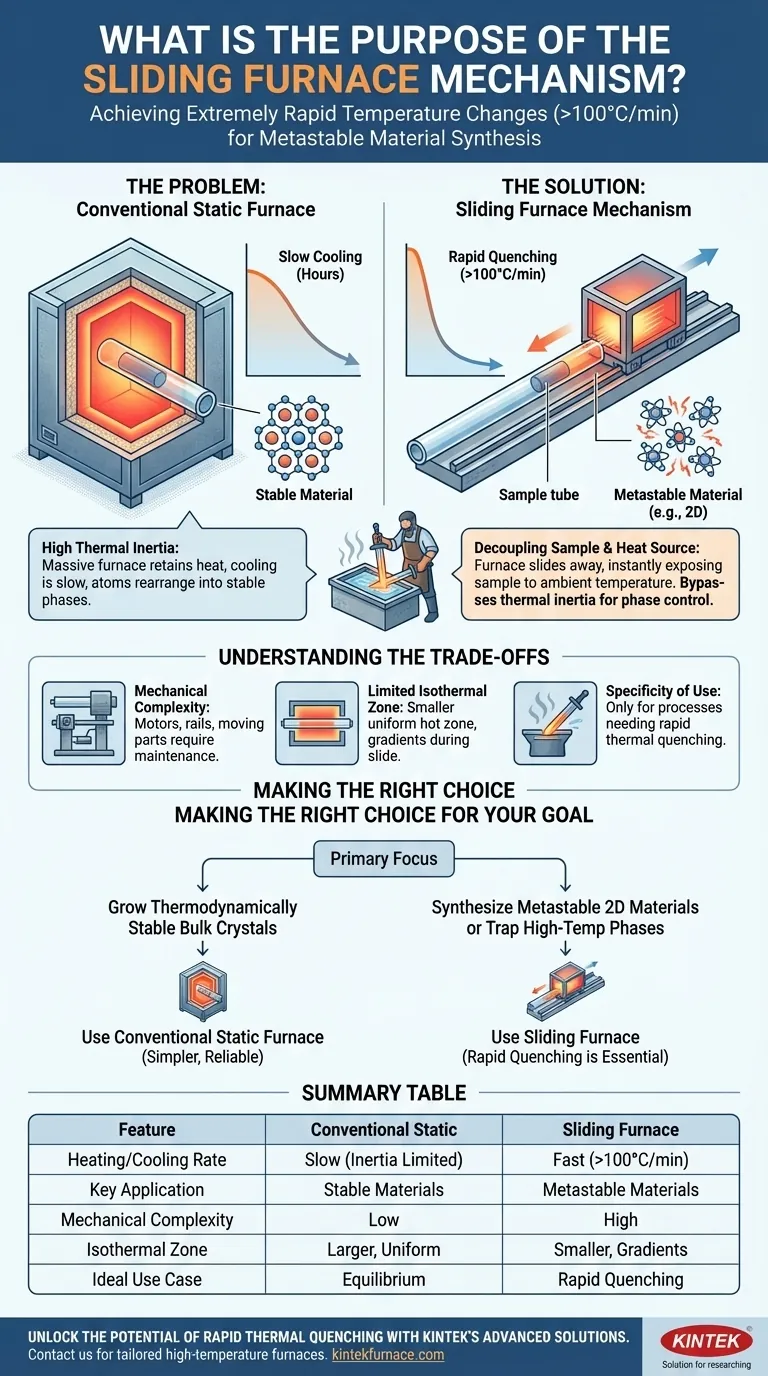

At its core, a sliding furnace mechanism is designed to achieve extremely rapid changes in temperature. Instead of waiting for a massive furnace to slowly heat up or cool down, this system physically moves the hot furnace zone away from the sample, or vice versa, to expose it to a different temperature environment almost instantly.

The sliding furnace bypasses the fundamental problem of thermal inertia. By physically separating the heat source from the sample, it enables heating and cooling rates exceeding 100°C/min, a capability that is critical for synthesizing materials that cannot form under slow, equilibrium conditions.

The Problem with Conventional Static Furnaces

To understand the value of a sliding furnace, you must first recognize the inherent limitation of a traditional, stationary tube furnace.

The Challenge of Thermal Inertia

A standard furnace is built with thick insulation and heavy heating elements designed to hold a stable temperature for long periods. This mass, while excellent for stability, creates high thermal inertia.

Once heated, the furnace retains a tremendous amount of energy. It cannot cool down quickly, as it must radiate all that stored heat into the surrounding environment, a process that can take hours.

The Barrier to Metastable Materials

This slow cooling process is a major obstacle for certain advanced materials. As a material cools slowly, its atoms have ample time to arrange themselves into their most stable, lowest-energy configuration.

However, many scientifically interesting material phases are metastable—they are trapped in a higher-energy state. These phases often possess unique electronic or physical properties but will only form if the material is "quenched" or cooled so rapidly that the atoms are frozen in place before they can rearrange.

How the Sliding Mechanism Provides a Solution

A sliding furnace solves the thermal inertia problem not by trying to cool the furnace itself, but by mechanically changing the sample's environment.

Decoupling the Sample and Heat Source

The core principle is simple: the furnace remains at its target temperature, and the sample tube remains stationary. The mechanism allows the entire furnace body to slide along the tube.

To heat the sample, the furnace slides over it. To "cool" the sample, the furnace slides away, instantly exposing that section of the tube to ambient room temperature. This provides a near-instantaneous temperature drop.

Achieving Unprecedented Ramp Rates

This physical movement is what enables cooling and heating rates of more than 100°C/min. The sample's temperature change is limited only by the speed of the slide and how quickly the small sample itself can shed heat, not by the cooling rate of a multi-kilogram furnace.

Think of it like a blacksmith quenching a red-hot sword. The blacksmith doesn't wait for the forge to cool down; they plunge the sword into water for an immediate phase change. The sliding furnace is a highly controlled, automated version of this principle for advanced material synthesis.

Understanding the Trade-offs

While powerful, the sliding mechanism introduces its own set of considerations that are not present in simpler static systems.

Mechanical Complexity

The addition of motors, rails, and control systems increases the mechanical complexity of the equipment. These moving parts require maintenance and can be a potential point of failure compared to a solid-state static furnace.

Limited Isothermal Zone

The "hot zone," or the area of perfectly uniform temperature, is often smaller in a sliding furnace design. Furthermore, during the slide itself, a temperature gradient will exist across the sample, which may be undesirable for certain growth processes.

Specificity of Use

This capability is not universally required. For the vast majority of processes where materials form under thermal equilibrium, the complexity and cost of a sliding furnace are unnecessary. Its use is justified only when rapid thermal quenching is a prerequisite for success.

Making the Right Choice for Your Goal

The decision to use a sliding furnace depends entirely on the atomic structure you are trying to achieve.

- If your primary focus is growing thermodynamically stable bulk crystals: A conventional static furnace is simpler, more reliable, and perfectly suited for the task.

- If your primary focus is synthesizing metastable 2D materials or "trapping" high-temperature phases: The rapid quenching enabled by a sliding furnace is not just a benefit—it is often the only way to succeed.

By controlling the rate of temperature change so dramatically, the sliding furnace gives you command over not just the material's composition, but its very structural phase.

Summary Table:

| Feature | Conventional Static Furnace | Sliding Furnace Mechanism |

|---|---|---|

| Heating/Cooling Rate | Slow (limited by thermal inertia) | Fast (>100°C/min) |

| Key Application | Thermodynamically stable materials | Metastable materials (e.g., 2D materials) |

| Mechanical Complexity | Low | High (with moving parts) |

| Isothermal Zone | Larger and more uniform | Smaller, with gradients during sliding |

| Ideal Use Case | Equilibrium processes | Rapid quenching for phase control |

Unlock the potential of rapid thermal quenching in your lab with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse range of high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, such as synthesizing metastable materials. Contact us today to discuss how our tailored solutions can enhance your research efficiency and outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety