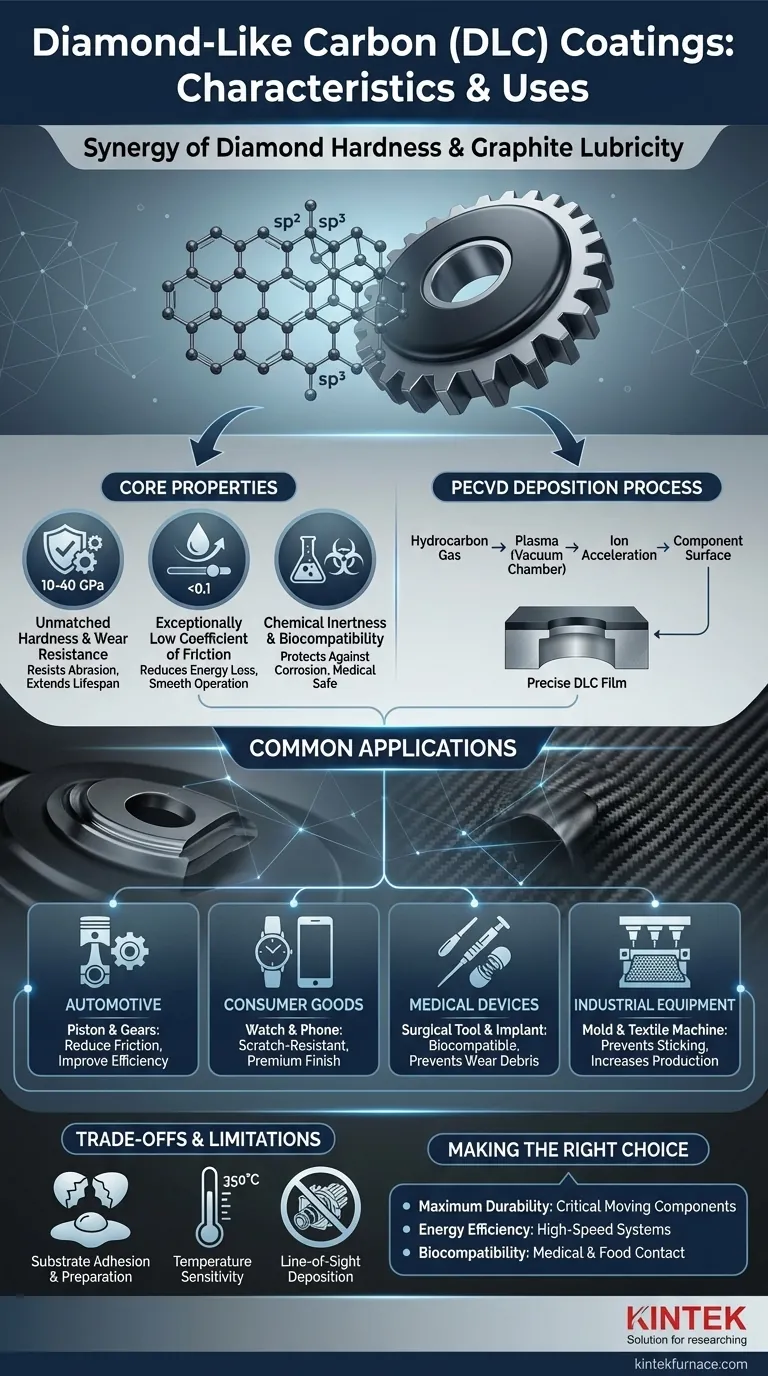

At its core, diamond-like carbon (DLC) is a class of amorphous carbon coatings that display some of the unique properties of natural diamond. These coatings are not pure diamond but rather a mixture of diamond-like (sp3) and graphite-like (sp2) carbon bonds, which grants them an exceptional combination of high hardness and a low coefficient of friction.

The true value of DLC is not found in a single characteristic, but in the synergy of its properties. It simultaneously provides the hardness of a ceramic and the lubricity of graphite, solving complex engineering challenges where wear, friction, and chemical stability are all critical concerns.

Deconstructing the Key Properties of DLC

Understanding why DLC is specified requires looking beyond a simple list of features. Each property solves a distinct set of problems.

Unmatched Hardness and Wear Resistance

The high ratio of diamond-like sp3 carbon bonds gives DLC coatings extreme hardness, often in the range of 10-40 GPa, approaching that of natural diamond.

This hardness directly translates into superior wear and abrasion resistance. Components coated with DLC are highly resilient to scratching and material loss from mechanical contact, drastically extending their operational lifespan.

Exceptionally Low Coefficient of Friction

Simultaneously, the presence of graphite-like sp2 bonds gives the surface a very low coefficient of friction, often below 0.1 in dry conditions.

This property is critical for reducing energy loss and heat generation in moving parts. It allows components to slide against each other with minimal resistance, enabling smooth, efficient operation even without traditional liquid lubricants.

Chemical Inertness and Biocompatibility

DLC is an amorphous, hydrogenated carbon film, making it highly non-reactive. It acts as an excellent chemical barrier, protecting the underlying substrate from corrosion and chemical attack.

This inertness also makes many forms of DLC highly biocompatible. The human body does not typically recognize the coating as a foreign material, which prevents adverse immune responses and makes it ideal for medical applications.

The Deposition Process (PECVD)

Most DLC coatings are applied using a vacuum deposition process called Plasma-Enhanced Chemical Vapor Deposition (PECVD).

In this process, a hydrocarbon gas (like methane) is introduced into a vacuum chamber and dissociated by a plasma. The resulting carbon ions are then accelerated toward the component's surface, where they form the dense, hard DLC film. The thickness is precisely controlled by the deposition time.

Common Applications: Where DLC Delivers Value

The unique combination of properties makes DLC a high-performance solution across several demanding industries.

High-Performance Automotive Components

In engines, DLC is applied to piston rings, wrist pins, and valvetrain components. The goal is to reduce parasitic friction, which improves fuel efficiency and lowers emissions while simultaneously preventing wear in high-load areas.

Durable Consumer and Luxury Goods

DLC provides a premium, scratch-resistant finish for high-end watches, phone casings, and other electronics. It protects the aesthetic of the product while providing a distinct, high-quality tactile feel.

Critical Medical and Biomedical Devices

Due to its biocompatibility and hardness, DLC is used to coat surgical instruments and orthopedic implants, such as hip and knee joints. The coating prevents wear debris from entering the body and ensures a long, stable implant life.

Industrial and Manufacturing Equipment

In textile machinery, food processing equipment, and industrial molds, DLC coatings reduce friction on sliding components and prevent material from sticking to surfaces. This improves production speed and reduces downtime for cleaning and maintenance.

Understanding the Trade-offs and Limitations

While powerful, DLC is not a universal solution. A proper technical assessment requires acknowledging its limitations.

Substrate Adhesion and Preparation

DLC's performance is highly dependent on its adhesion to the substrate. The component surface must be meticulously cleaned and prepared. Furthermore, applying a very hard coating to a soft substrate can create an "egg-shell effect," where the coating can crack or delaminate under a sharp impact.

Temperature Sensitivity

Most standard DLC coatings begin to break down and lose their beneficial properties at temperatures above 350°C (662°F). This makes them unsuitable for very high-temperature applications where other ceramic coatings might be a better fit.

Line-of-Sight Deposition

Because PECVD is a line-of-sight process, coating complex internal geometries or hidden features can be challenging or impossible. Parts must be fixtured carefully to ensure uniform coating exposure.

Making the Right Choice for Your Project

Your decision to use DLC should be driven by the primary problem you need to solve.

- If your primary focus is maximum durability and wear resistance: Specify DLC for critical moving components that face constant abrasion or sliding contact.

- If your primary focus is energy efficiency and low friction: Use DLC in systems where reducing parasitic energy loss and heat is paramount, such as in high-speed machinery or internal combustion engines.

- If your primary focus is biocompatibility and chemical resistance: Choose DLC for medical devices, implants, or food-contact equipment where surface inertness is a non-negotiable safety requirement.

By understanding its core strengths and limitations, you can leverage diamond-like carbon to engineer products that are fundamentally more resilient, efficient, and long-lasting.

Summary Table:

| Property | Description | Key Benefits |

|---|---|---|

| Hardness and Wear Resistance | High sp3 carbon bond ratio (10-40 GPa) | Extends component lifespan, resists abrasion |

| Low Coefficient of Friction | Graphite-like sp2 bonds (<0.1 in dry conditions) | Reduces energy loss, enables smooth operation |

| Chemical Inertness | Amorphous, hydrogenated carbon film | Protects against corrosion, biocompatible for medical use |

| Deposition Process | Plasma-Enhanced Chemical Vapor Deposition (PECVD) | Precise, controlled coating application in vacuum |

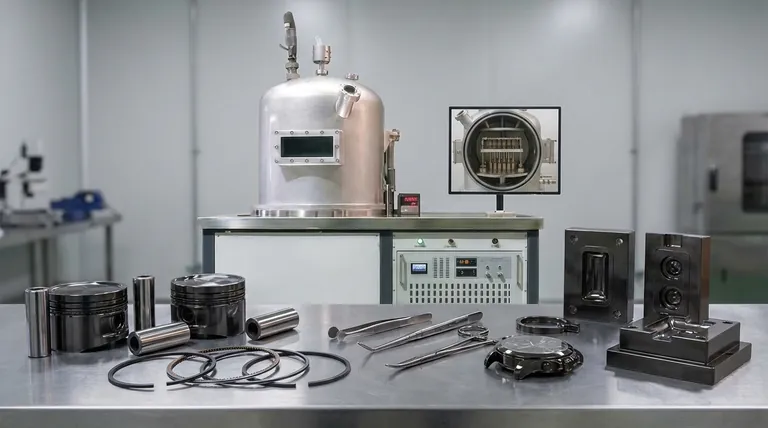

Unlock the full potential of your projects with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored DLC coating systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing durability, efficiency, and performance in automotive, medical, and industrial applications. Contact us today to discuss how we can elevate your innovations!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the key properties of diamond that make it a promising semiconductor material? Unlock Next-Gen Electronics

- What is Hot-filament Chemical Vapor Deposition (HFCVD)? Achieve High-Quality Thin Films with Precision Control

- How does a CVD machine work? Master the Technology for High-Quality Thin Film Deposition

- What are the advantages of CVD? Achieve Unmatched High-Purity, Conformal Thin Films

- What is a CVD machine? Build High-Performance Materials from Gas with Precision