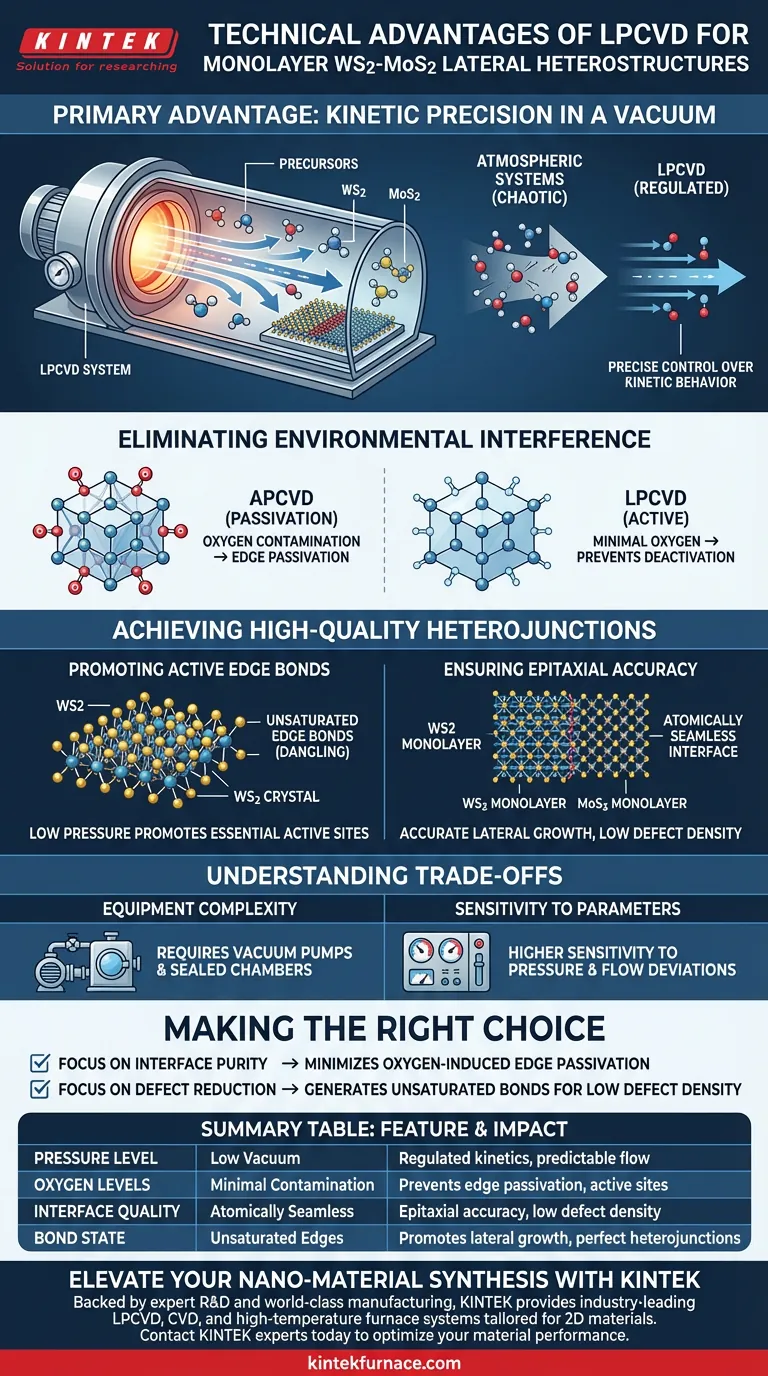

The primary advantage of Low-Pressure Chemical Vapor Deposition (LPCVD) is kinetic precision. By operating in a vacuum environment, this system allows you to strictly regulate precursor behavior, minimizing the interference of environmental oxygen to ensure high-quality crystal growth.

The core value of LPCVD lies in its ability to prevent edge passivation. By maintaining a low-pressure environment, the system preserves unsaturated edge bonds, enabling the growth of atomically seamless interfaces with exceptionally low defect densities.

The Mechanism of Growth Control

Regulating Kinetic Behavior

In an LPCVD system, the reduced pressure alters the mean free path of gas molecules. This environment provides the operator with precise control over the kinetic behavior of the precursor vapors.

Unlike atmospheric systems, where gas interactions can be chaotic, the low-pressure setting ensures that the movement and reaction of precursors are predictable and directed.

Eliminating Environmental Interference

A critical technical advantage is the significant reduction of environmental oxygen within the chamber.

Oxygen is a primary contaminant that leads to edge passivation—a process where the edges of a crystal become chemically inert. By removing oxygen, LPCVD prevents this deactivation from occurring.

Achieving High-Quality Heterojunctions

Promoting Active Edge Bonds

For a lateral heterostructure to form correctly, the edge of the first material (e.g., WS2) must remain chemically active to accept the second material (e.g., MoS2).

The low-pressure conditions in LPCVD promote the generation of unsaturated edge bonds. These "dangling" bonds are the essential active sites required for continued lateral growth.

Ensuring Epitaxial Accuracy

Because the edges remain active and unpassivated, the system facilitates accurate edge epitaxial growth.

This precision results in a heterojunction interface that is atomically seamless. The final structure exhibits a low defect density, which is critical for the electronic and optical performance of the device.

Understanding the Trade-offs

Equipment Complexity

While LPCVD offers superior control, it requires a vacuum environment. This necessitates the use of vacuum pumps and vacuum-sealed chambers, making the hardware more complex than Atmospheric Pressure CVD (APCVD) systems.

Sensitivity to Process Parameters

The "precise control" mentioned as an advantage also implies a higher sensitivity to variables. Because the process relies on specific kinetic behaviors, deviations in pressure or precursor flow rates can disrupt the formation of unsaturated bonds.

Making the Right Choice for Your Goal

When deciding if LPCVD is the correct method for your specific heterostructure application, consider the following:

- If your primary focus is interface purity: LPCVD is the definitive choice because it minimizes oxygen-induced edge passivation, ensuring a seamless junction.

- If your primary focus is defect reduction: The ability to generate unsaturated edge bonds makes this system ideal for achieving low defect densities in lateral growth.

LPCVD transforms the challenge of edge passivation into an opportunity for precise, atomically perfect structural growth.

Summary Table:

| Feature | LPCVD Advantage | Impact on WS2-MoS2 Growth |

|---|---|---|

| Pressure Level | Low Vacuum | Regulated kinetic behavior and predictable precursor flow |

| Oxygen Levels | Minimal Contamination | Prevents edge passivation for active growth sites |

| Interface Quality | Atomically Seamless | Ensures epitaxial accuracy with low defect density |

| Bond State | Unsaturated Edges | Promotes lateral growth for perfect heterojunctions |

Elevate Your Nano-Material Synthesis with KINTEK

Precision at the atomic level requires more than just high temperatures; it demands a controlled environment. Backed by expert R&D and world-class manufacturing, KINTEK provides industry-leading LPCVD, CVD, and high-temperature furnace systems tailored for the growth of 2D materials like WS2 and MoS2.

Whether you need customizable vacuum systems or high-precision lab equipment, our solutions are designed to eliminate defects and ensure seamless epitaxial growth. Contact KINTEK experts today to discuss your unique research needs and discover how our advanced furnace technology can optimize your material performance.

Visual Guide

References

- Pargam Vashishtha, Sumeet Walia. Epitaxial Interface‐Driven Photoresponse Enhancement in Monolayer WS<sub>2</sub>–MoS<sub>2</sub> Lateral Heterostructures. DOI: 10.1002/adfm.202512962

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the role of a Chemical Vapor Deposition (CVD) system? Precision Growth for Nanoporous Capillary Grippers

- What is the function of a high vacuum pump in CVD? Ensure High-Purity ITO Thin Film Growth

- What are the typical process temperature ranges for HT CVD and MT CVD processes? Optimize Your Coating Performance

- Which materials are commonly employed in CVD coatings? Discover Key Materials for Superior Surface Protection

- What is chemical vapor phase deposition? Unlock High-Performance Thin Films for Your Lab

- What materials are commonly used in CVD coating systems? Explore Key Materials for Superior Coatings

- What are the technical advantages of using EPD equipment for SiCf/SiC interface layer preparation? | EPD vs CVD/CVI

- How is CVD used in electronics manufacturing? Build High-Purity, Uniform Layers for Advanced Electronics