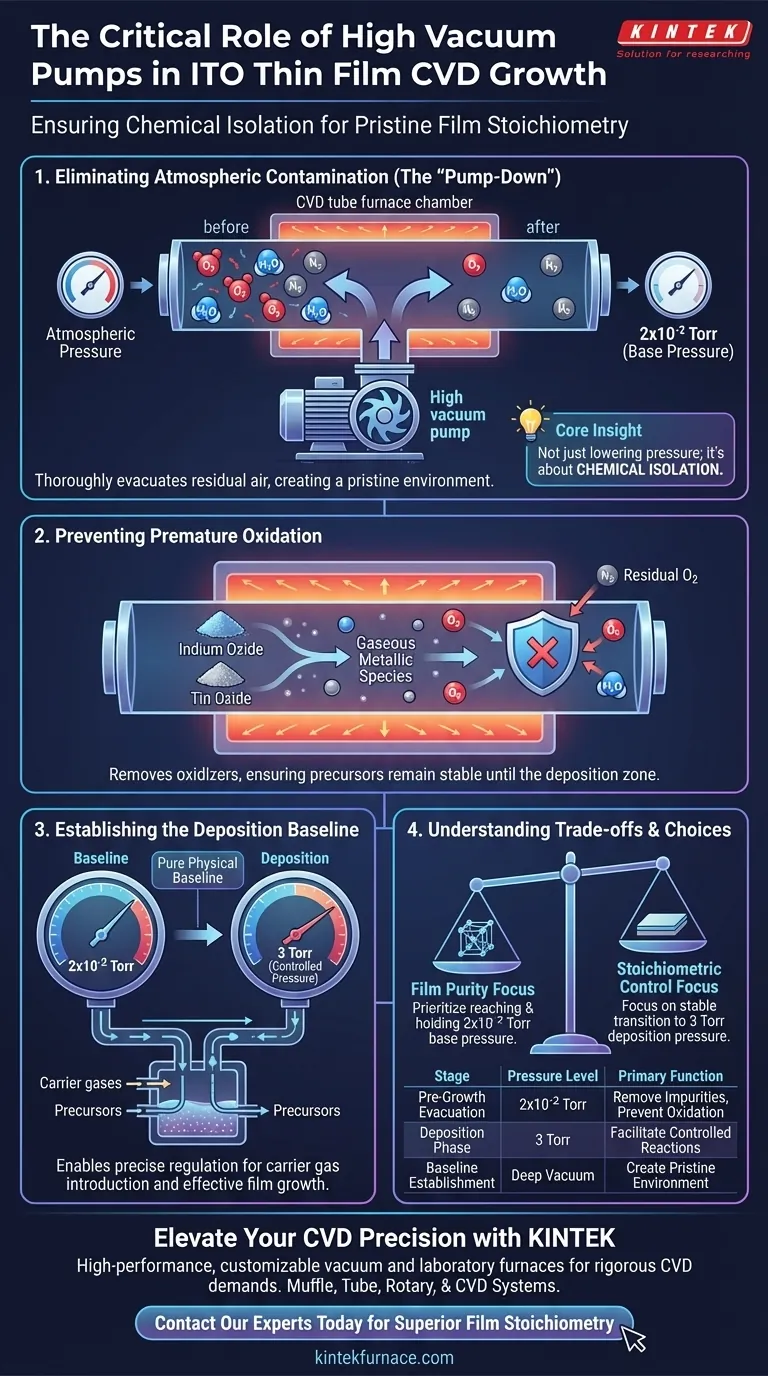

The high vacuum pump system functions as a critical purification mechanism within the CVD process, reducing the tube furnace pressure to approximately 2x10^-2 Torr before growth begins. Its specific role is to thoroughly evacuate residual air and impurity gases, creating a pristine environment that prevents precursor oxidation and establishes the physical baseline required for controlled deposition.

Core Insight: The vacuum system is not merely about lowering pressure; it is about chemical isolation. By stripping the chamber of atmospheric contaminants, it ensures that the high-temperature reaction is driven solely by your intended precursors, protecting the film’s stoichiometry from uncontrolled environmental variables.

The Critical Role of Chamber Evacuation

Eliminating Atmospheric Contamination

The immediate function of the high vacuum pump is the removal of residual air and impurity gases from the furnace chamber.

Standard atmospheric air contains oxygen, water vapor, and nitrogen, all of which can interfere with the delicate chemical reactions required for ITO growth.

By reducing the pressure to 2x10^-2 Torr, the system effectively "resets" the chamber environment, ensuring that no unintended chemical species are present when heating begins.

Preventing Premature Oxidation

A major risk in Indium Tin Oxide (ITO) synthesis is the premature oxidation of precursors.

The process involves converting Indium Oxide and Tin Oxide into gaseous metallic species. If residual oxygen is present during the ramp-up phase, these precursors can react uncontrollably before reaching the substrate.

The high vacuum environment removes the oxidizers that cause this degradation, ensuring the precursors remain stable until they reach the deposition zone.

Establishing the Deposition Baseline

Enabling Precise Pressure Regulation

While the pump achieves a high vacuum (2x10^-2 Torr) initially, the actual deposition occurs at a higher, controlled pressure of 3 Torr.

The high vacuum step provides the pure physical baseline necessary to regulate this upward shift in pressure accurately.

Starting from a deep vacuum allows the system to introduce carrier gases and precursors with precision, establishing the specific mean free path required for effective film growth.

Understanding the Trade-offs

Vacuum Depth vs. Process Efficiency

It is critical to distinguish between the base pressure (2x10^-2 Torr) and the deposition pressure (3 Torr).

Attempting to perform deposition at the base pressure would likely result in a mean free path that is too long, preventing the necessary gas-phase collisions for film growth.

Conversely, failing to reach the 2x10^-2 Torr base pressure before introducing gases effectively traps contaminants in the film. The trade-off is time: the system requires a dedicated "pump-down" phase before growth can commence to ensure purity.

Making the Right Choice for Your Goal

To optimize your ITO thin film growth, consider how you manage the vacuum stage:

- If your primary focus is Film Purity: Ensure your pump system reliably reaches and holds 2x10^-2 Torr to eliminate all water vapor and residual oxygen before heating the precursors.

- If your primary focus is Stoichiometric Control: Focus on the stability of the transition from the base vacuum to the 3 Torr deposition pressure, as this shift defines the reaction kinetics.

The vacuum system is the gatekeeper of quality, ensuring that the CVD process begins on a foundation of chemical purity rather than atmospheric chance.

Summary Table:

| Stage | Pressure Level | Primary Function |

|---|---|---|

| Pre-Growth Evacuation | 2x10^-2 Torr | Removes residual air, moisture, and impurities to prevent oxidation |

| Deposition Phase | 3 Torr | Facilitates controlled chemical reactions and gas-phase collisions |

| Baseline Establishment | Deep Vacuum | Creates a pristine environment for precise carrier gas introduction |

Elevate Your CVD Precision with KINTEK

Don't let atmospheric contaminants compromise your thin film quality. KINTEK provides high-performance vacuum systems and laboratory high-temperature furnaces specifically designed for the rigorous demands of Chemical Vapor Deposition.

Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique research or production needs. Whether you are optimizing ITO growth or developing new material coatings, our equipment ensures the chemical isolation and pressure stability required for excellence.

Ready to achieve superior film stoichiometry? Contact our technical experts today to find the perfect furnace solution for your lab.

Visual Guide

References

- Muchammad Yunus, Azianty Saroni. Effect of Deposition Temperature on The Structural and Crystallinity Properties of Self-Catalyzed Growth Indium Tin Oxide (ITO) Thin Film Using CVD Technique. DOI: 10.24191/srj.v22i2.23000

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What biomedical applications do CVD furnaces have? Enhance Implant Safety and Drug Delivery

- What are the equipment for chemical vapor deposition? A Guide to the 5 Essential Components

- Why study beta-BiAsO2 epitaxial growth on SiO2? Unlock High-Performance Topological Device Development

- What recent advancements have been made in CVD system design? Explore Innovations for Research and Industry

- What role do catalysts play in graphene production? Unlock Efficient, High-Quality Synthesis

- What are the two main types of CVD reactors? Choose the Right System for Your Lab

- In which industries is CVD particularly valuable? Unlock High-Performance Surface Engineering

- What is the function of high-purity Argon (Ar) gas during CVD? Optimize Your Thin Film Uniformity and Purity