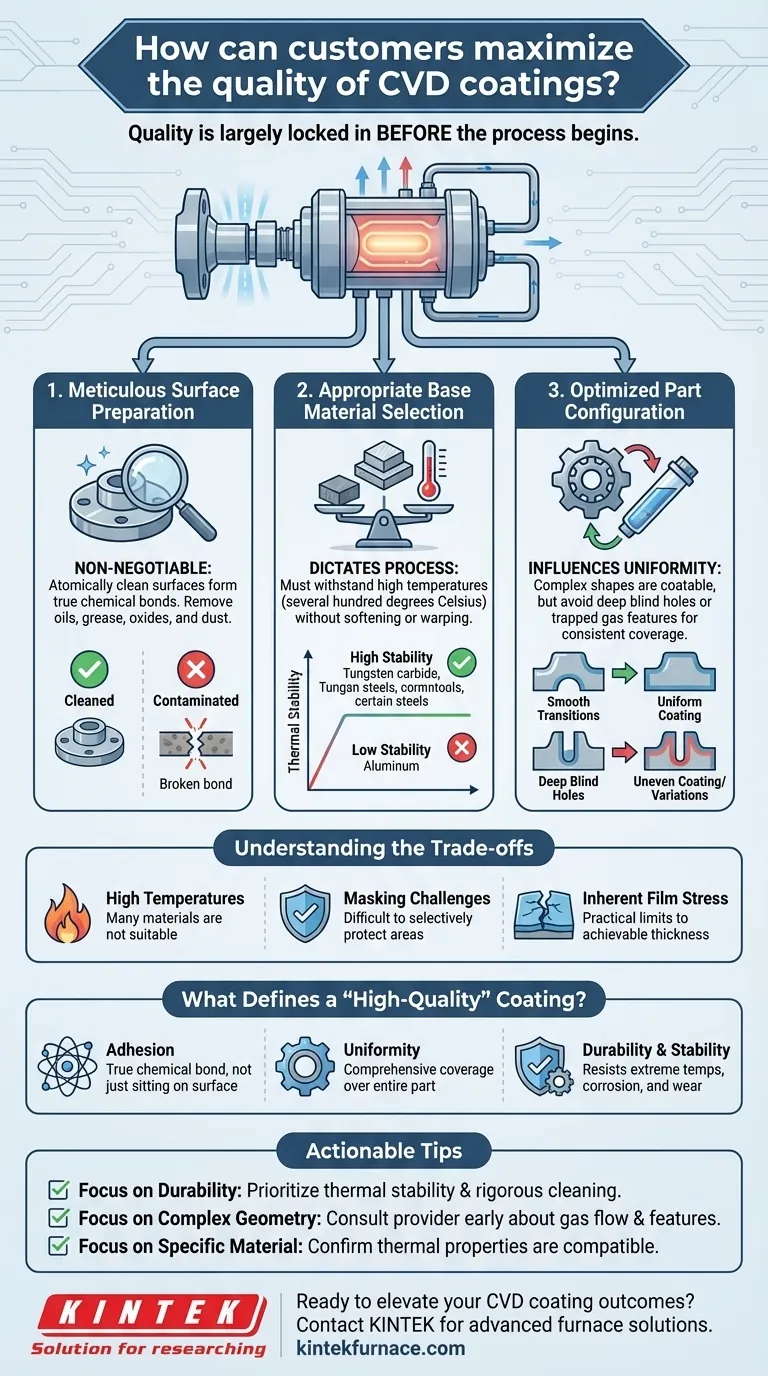

To maximize the quality of a Chemical Vapor Deposition (CVD) coating, you must focus on three factors entirely within your control: meticulous surface preparation, appropriate base material selection, and optimized part configuration. While the coating provider manages the complex process parameters, the ultimate success is determined by the quality and suitability of the part you provide.

The most critical insight is that the quality of a CVD coating is largely locked in before the coating process ever begins. Your decisions regarding the part's material, surface condition, and geometry create the fundamental foundation for the coating's adhesion, uniformity, and performance.

The Foundation: Why Your Decisions Matter

CVD is not a simple paint or plating process; it is a high-temperature chemical reaction. The surface of your part acts as a catalyst and a bonding site where precursor gases react to grow a new, solid film.

Your part is an active ingredient in this reaction. Its properties directly dictate the outcome.

Principle 1: Surface Preparation is Non-Negotiable

A CVD coating forms a true chemical bond with the substrate. Any contaminant, no matter how small, acts as a barrier that prevents this bond from forming correctly.

Surfaces must be atomically clean. This means they are completely free of oils, grease, oxide layers, dust, and any other residue from prior manufacturing steps. A contaminated surface leads directly to poor adhesion and potential coating failure.

Principle 2: Base Material Dictates the Process

The CVD process occurs at elevated temperatures, often several hundred degrees Celsius. Your chosen base material must be able to withstand this heat without softening, warping, or changing its fundamental properties.

This thermal stability requirement is why material selection is so crucial. A material that cannot handle the reaction temperature limits the provider's ability to optimize the process, compromising the final coating quality.

Principle 3: Part Geometry Influences Uniformity

A key advantage of CVD is that it is not a "line-of-sight" process, allowing it to coat complex shapes. The reactive gases flow around the part, coating all exposed surfaces.

However, extremely complex internal passages or very deep, narrow blind holes can create issues with gas flow. These features can lead to variations in coating thickness or incomplete coverage. Designing parts with smoother transitions and avoiding geometries that can trap gas will yield a more uniform and reliable coating.

Understanding the Trade-offs of CVD

To make informed decisions, you must understand the inherent characteristics and limitations of the process itself. This knowledge allows you to design for success.

The Impact of High Temperatures

The primary trade-off is the heat. Many materials, such as heat-treated tool steels that would lose their temper, most aluminum alloys, and plastics, are not suitable for standard CVD processes. You must select a substrate that is thermally stable at the required reaction temperature.

The Challenge of Masking

Because CVD relies on a reactive gas that fills the entire chamber, it is very difficult to "mask" or selectively protect certain areas of a part from being coated. The process naturally wants to coat everything it can reach.

Inherent Film Stress and Thickness Limits

As the CVD film grows thicker, internal stresses build within the coating. If the thickness exceeds a certain limit for a given material system, this stress can cause the coating to crack or delaminate from the surface. There is always a practical limit to the achievable coating thickness.

What Defines a "High-Quality" CVD Coating?

When you control for the foundational factors, you enable the CVD process to deliver its unique advantages, which define a high-quality outcome.

Adhesion: A True Chemical Bond

The single greatest measure of quality is adhesion. A successful CVD process creates a powerful, direct chemical bond between the coating and the substrate atoms. The coating doesn't just sit on the surface; it becomes an integral part of it.

Uniformity: Comprehensive Coverage

Quality is also measured by uniformity. A well-executed process provides exceptional control over thickness, ensuring the entire part—including complex geometries—receives a consistent and complete coating layer.

Durability and Stability

The resulting film is dense, durable, and highly stable. These coatings are designed to withstand extreme temperatures, corrosive environments, and significant mechanical wear, far surpassing the capabilities of many other surface treatments.

How to Apply This to Your Project

Your choices in the design phase are your most powerful tool for maximizing coating quality. Use these guidelines to align your design with your primary goal.

- If your primary focus is maximum durability and adhesion: Prioritize selecting a thermally stable base material and implementing a rigorous, multi-stage cleaning process before sending the part for coating.

- If your primary focus is coating a complex geometry: Consult with your coating provider early in the design process to discuss gas flow and ensure features like internal channels or blind holes are accessible.

- If your primary focus is performance on a specific material: Confirm that your material's thermal properties are compatible with the temperatures required for the desired coating.

Proactive collaboration and designing for coatability are the keys to unlocking the full performance potential of CVD technology.

Summary Table:

| Key Factor | Why It Matters | Actionable Tips |

|---|---|---|

| Surface Preparation | Ensures strong chemical bonding; prevents adhesion failure | Use rigorous cleaning to remove oils, oxides, and contaminants |

| Base Material Selection | Must withstand high CVD temperatures without warping | Choose thermally stable materials like certain steels or ceramics |

| Part Geometry | Affects gas flow and coating uniformity | Design with smooth transitions; avoid deep blind holes for even coverage |

Ready to elevate your CVD coating outcomes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our deep customization capabilities ensure we can precisely meet your unique experimental requirements, helping you achieve superior adhesion, uniformity, and durability in your coatings. Don't leave quality to chance—contact us today to discuss how our tailored solutions can benefit your lab!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials