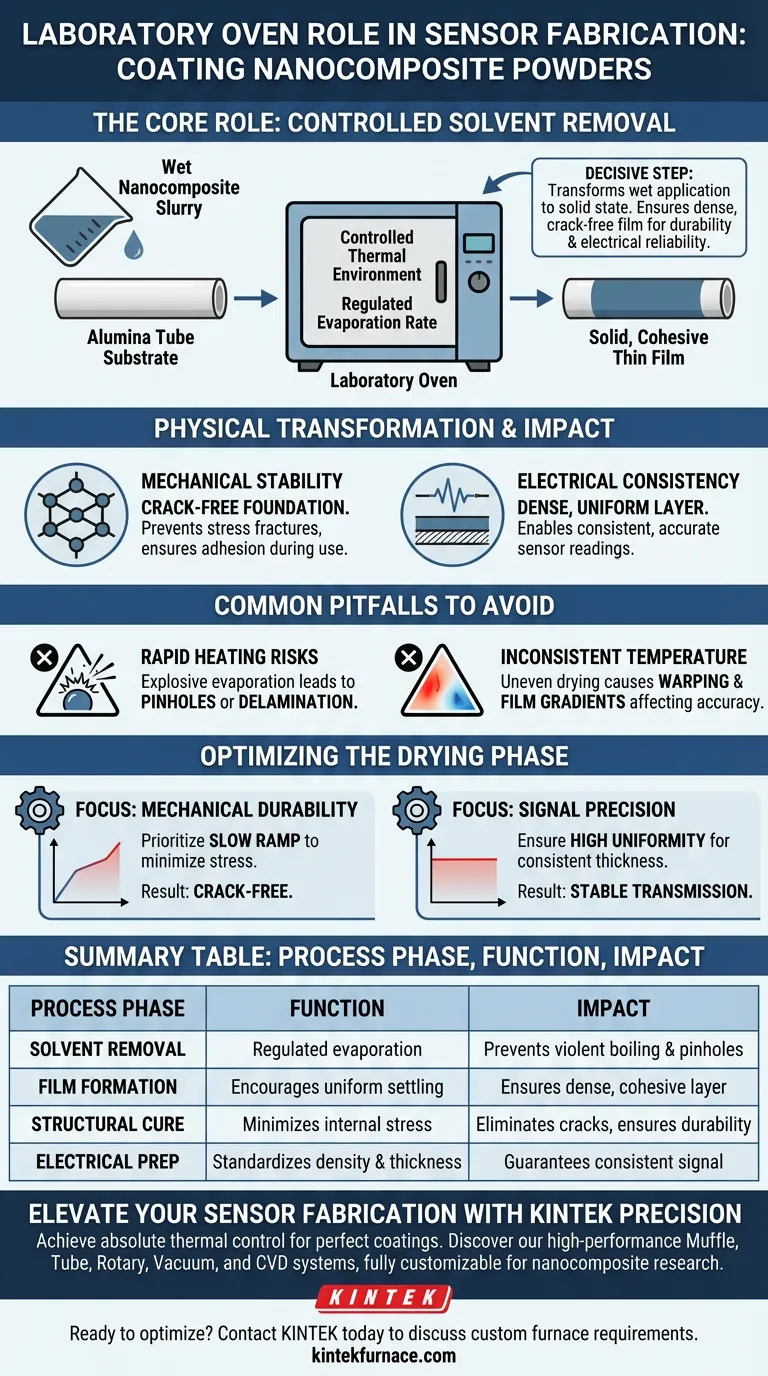

The primary role of a laboratory oven in this context is to facilitate controlled solvent removal. After a nanocomposite slurry is applied to an alumina tube substrate, the oven creates the specific thermal environment necessary to evaporate solvents at a regulated rate. This process is the decisive step that transforms the wet application into a cohesive, solid state.

By managing the drying rate, the laboratory oven ensures the sensing layer solidifies into a dense, crack-free thin film, which is the prerequisite for both mechanical durability and reliable electrical performance.

The Physical Transformation Process

Controlled Solvent Evaporation

The immediate function of the oven is to remove the liquid components used to create the nanocomposite slurry. This is not merely about heating; it is about establishing a controlled temperature profile that prevents the solvents from boiling off too violently.

Formation of the Thin Film

As the solvents evaporate, the remaining nanocomposite powders settle and bond. The oven ensures this settling process results in a dense thin film rather than a porous or uneven layer.

Preventing Structural Defects

A regulated drying environment is essential to prevent the formation of cracks. If the slurry dries unevenly or too rapidly, the resulting film will suffer from stress fractures that compromise the entire sensor assembly.

Impact on Sensor Performance

Establishing Mechanical Stability

The drying phase serves as the physical foundation for the sensor. By ensuring a crack-free coating on the alumina tube, the oven guarantees that the sensing element remains mechanically stable and adhered to the substrate during use.

Ensuring Electrical Consistency

The physical quality of the film directly dictates its electrical properties. A dense, uniform layer created by proper oven drying allows for the consistency of subsequent electrical signal transmissions, which is critical for accurate sensor readings.

Common Pitfalls to Avoid

Risks of Rapid Heating

If the oven temperature is set too high initially, solvents may evaporate explosively. This leads to pinholes or delamination, ruining the sensor before it can be used.

Inconsistent Temperature Distribution

An oven with poor air circulation can create hot and cool spots. This results in uneven drying across the alumina tube, causing warping or gradients in the film density that affect sensor accuracy.

Optimizing the Drying Phase

To maximize the quality of your sensor fabrication, align your oven settings with your specific performance goals:

- If your primary focus is Mechanical Durability: Prioritize a slow, ramped temperature increase to minimize internal stress and ensure the film remains crack-free.

- If your primary focus is Signal Precision: Ensure the oven provides a highly uniform temperature distribution to create a perfectly dense, consistent film thickness for stable electrical transmission.

The laboratory oven is not a passive heating tool, but an active instrument for defining the structural integrity of your sensor.

Summary Table:

| Process Phase | Function of Laboratory Oven | Impact on Sensor Quality |

|---|---|---|

| Solvent Removal | Regulated evaporation via controlled temperature profiles | Prevents violent boiling and pinhole formation |

| Film Formation | Encourages uniform settling of nanocomposite powders | Ensures a dense, cohesive, and even sensing layer |

| Structural Cure | Minimizes internal thermal stress during drying | Eliminates cracks and ensures mechanical durability |

| Electrical Prep | Standardizes layer density and thickness | Guarantees consistent and reliable signal transmission |

Elevate Your Sensor Fabrication with KINTEK Precision

Achieving the perfect thin-film coating requires more than just heat; it requires absolute thermal control. KINTEK provides high-performance laboratory solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—specifically designed to meet the rigorous demands of nanocomposite research.

Backed by our expert R&D and manufacturing, our systems are fully customizable to your unique sensor fabrication needs, ensuring your coatings are consistently dense, crack-free, and mechanically stable.

Ready to optimize your drying and sintering processes?

Contact KINTEK today to discuss your custom furnace requirements.

Visual Guide

References

- Sovandeb Sen, Susmita Kundu. Bio-waste derived reduced graphene oxide (rGO) decorated Cr (III) doped α-Fe2O3 nanocomposite for selective ppm-level acetone sensing at room temperature: Potential approach towards non-invasive diagnosis of diabetic biomarker. DOI: 10.1007/s42114-025-01241-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a laboratory constant temperature drying oven necessary for biomass adsorbents? Ensure Precision & Integrity

- How do industrial cameras and CNN improve surface defect detection? Revolutionize QC with 95%+ Accuracy

- Why is a blank control experiment without a sample required? Ensure Accuracy in Oxide Scale Measurement

- How does a constant temperature and humidity curing chamber contribute to GCCM hydration? Optimize Material Strength

- What are some common applications of PVD? Boost Performance with Advanced Thin-Film Coatings

- What technical advantages does a single-channel roller kiln offer? Optimize Your Fast Sintering Cycles

- What are the advantages of a benchtop industrial oven in terms of usability? Enhance Lab Efficiency with Compact Design

- What are the benefits of using a vacuum environment for RCM NSs? Master Material Preservation & Catalytic Performance