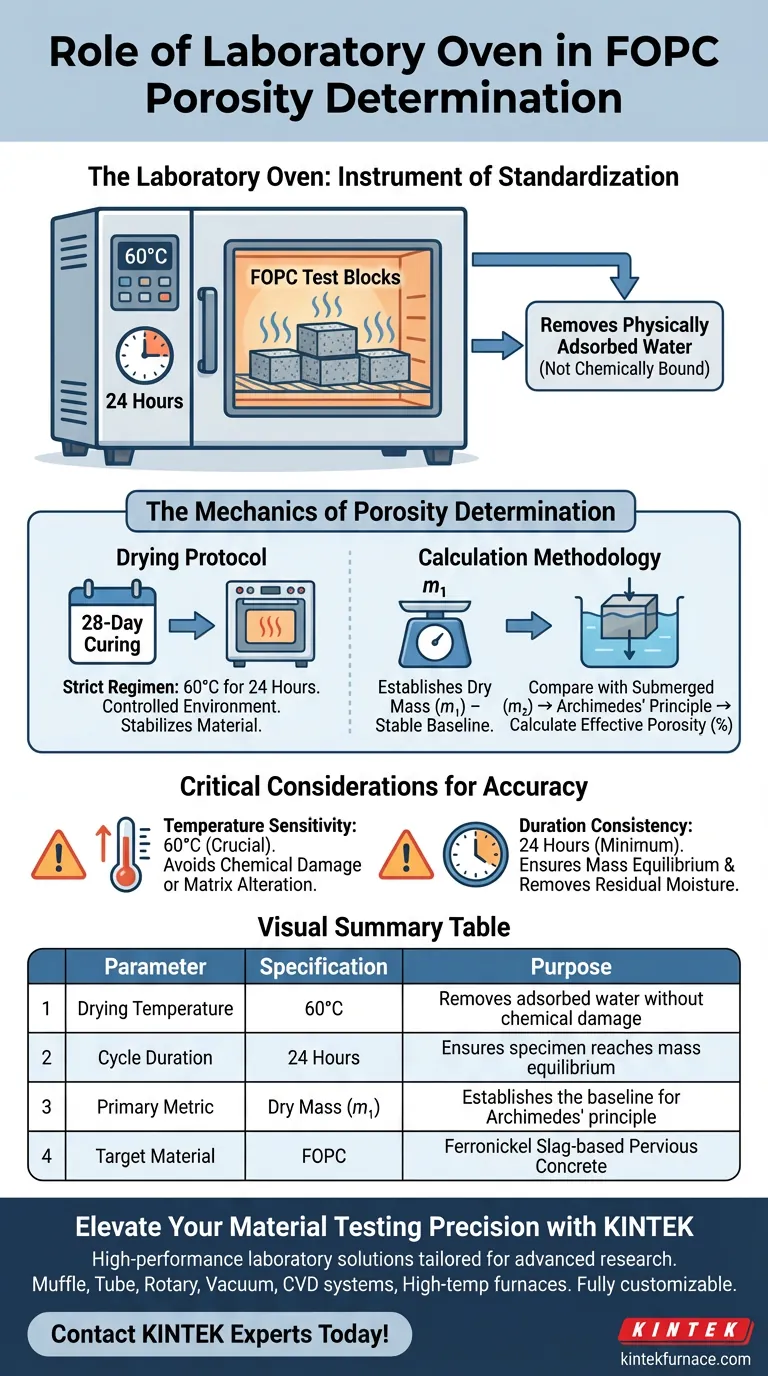

The laboratory oven serves as the instrument of standardization for determining the porosity of Ferronickel Slag-based Pervious Concrete (FOPC). Its specific role is to dry test blocks at a constant temperature of 60°C for 24 hours after the standard 28-day curing period. This process is essential to establish the precise dry mass ($m_1$) by removing physically adsorbed water.

Accurate porosity calculation depends entirely on establishing a consistent dry baseline. The laboratory oven ensures that all physically adsorbed moisture is removed from the concrete matrix, allowing for a precise comparison against the submerged mass using Archimedes' principle.

The Mechanics of Porosity Determination

To understand the oven's role, you must understand the specific protocol required to prepare FOPC samples for analysis.

The Drying Protocol

The primary reference dictates a strict drying regimen. After the concrete has cured for 28 days, it is placed in the laboratory oven at a specific setting of 60°C for 24 hours.

This is not an arbitrary setting; it is a controlled environment designed to stabilize the material without subjecting it to excessive thermal shock.

Removing Adsorbed Water

The target of this heating process is physically adsorbed water.

This refers to moisture that adheres to the surface and pores of the material but is not chemically bound to the concrete's structure. Removing this water is the only way to obtain a true "dry" state.

The Calculation Methodology

The data generated by the oven is the foundational variable in the mathematical formula used to determine porosity.

Establishing Dry Mass ($m_1$)

The weight of the sample after the 24-hour oven cycle is recorded as the dry mass ($m_1$).

Without the oven's ability to maintain a constant temperature, this mass would fluctuate based on ambient humidity, rendering the calculation invalid.

Applying Archimedes' Principle

The porosity is calculated by comparing the oven-dried mass ($m_1$) against the submerged mass ($m_2$).

By utilizing Archimedes' principle, the difference between these two states reveals the volume of void spaces (pores) within the concrete, providing the final effective porosity percentage.

Critical Considerations for Accuracy

While the process seems straightforward, adhering to the specific parameters provided in the reference is crucial to avoid data errors.

Temperature Sensitivity

The protocol specifies 60°C, which is notably lower than the 100°C+ often used for drying aggregates or soils.

Exceeding this temperature could potentially damage the cementitious matrix or drive off chemically bound water, which would skew the porosity results.

Duration Consistency

The 24-hour duration is the minimum requirement to ensure equilibrium.

Shortening this timeframe runs the risk of leaving residual moisture in the inner core of the sample, which would artificially inflate the measured mass ($m_1$) and result in an inaccurate lower porosity reading.

Making the Right Choice for Your Goal

To ensure your FOPC analysis yields reliable data, you must rigorously control the drying variables.

- If your primary focus is Standardization: Adhere strictly to the 60°C temperature setting to remove physically adsorbed water without altering the material's chemical structure.

- If your primary focus is Calculation Accuracy: Ensure the full 24-hour cycle is completed to establish a stable dry mass ($m_1$) for use in Archimedes' principle.

Precision in the oven leads to precision in the final porosity metric.

Summary Table:

| Parameter | Specification | Purpose |

|---|---|---|

| Drying Temperature | 60°C | Removes adsorbed water without chemical damage |

| Cycle Duration | 24 Hours | Ensures specimen reaches mass equilibrium |

| Primary Metric | Dry Mass ($m_1$) | Establishes the baseline for Archimedes' principle |

| Target Material | FOPC | Ferronickel Slag-based Pervious Concrete |

Elevate Your Material Testing Precision with KINTEK

In the rigorous world of concrete analysis, accuracy is non-negotiable. KINTEK provides high-performance laboratory solutions tailored for advanced research. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature furnaces. Whether you are analyzing FOPC porosity or engineering complex cementitious matrices, our equipment is fully customizable to meet your unique laboratory needs.

Ready to standardize your results? Contact our technical experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Zhongping Tang, Fan Feng. Performance Analysis of Ferronickel Slag-Ordinary Portland Cement Pervious Concrete. DOI: 10.3390/ma17071628

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the significance of the calcination process? Engineering SrMo1-xNixO3-δ Nanocrystals via Muffle Furnace

- What function does a muffle furnace serve in the synthesis of glass derived from rice husk ash? High-Temp Precision

- How do modern muffle furnaces achieve precise temperature control? Discover the Tech Behind Perfect Heat

- What safety precautions should be taken when using a Muffle furnace? Ensure Lab Safety with Expert Guidelines

- What is the function of a laboratory muffle furnace in the annealing process? Master Stress Relief and Stability

- What temperature ranges are available for box furnaces? Find the Perfect Fit for Your Thermal Processes

- What types of box furnaces are available based on power source? Choose Electric or Gas for Your Needs

- What are the specifications of a typical muffle furnace? Key Details for Precise High-Temp Control