At the heart of every modern muffle furnace lies a sophisticated partnership between digital intelligence and refined heating technology. These furnaces achieve precise temperature control by using high-purity electric heating elements governed by a PID (Proportional-Integral-Derivative) control system. This closed-loop system continuously measures the internal temperature and makes real-time power adjustments to maintain the setpoint with exceptional stability and uniformity.

True temperature precision is not about raw power, but about intelligent feedback. The critical innovation is the PID controller, which acts as the furnace's brain, constantly correcting deviations to ensure the temperature you set is the temperature you get, consistently and across the entire chamber.

The Core Components of Precision Control

Achieving stable and uniform heat requires more than just turning on a heating element. Three key components work in concert to deliver the precision demanded by scientific and industrial processes.

The Brain: The PID Controller

The PID controller is the central nervous system of the furnace. Instead of a simple on/off thermostat that causes wide temperature swings, a PID system is constantly making intelligent adjustments.

It operates on three principles:

- Proportional (P): This part reacts to the current difference between the set temperature and the actual temperature. The bigger the difference, the stronger the response.

- Integral (I): This part looks at the past error. It corrects for small, persistent deviations that the proportional term might ignore, eliminating drift over time.

- Derivative (D): This part anticipates the future by looking at the rate of temperature change. It dampens the controller's response as it approaches the setpoint to prevent overshooting the target.

Think of it as a highly skilled driver using cruise control, not just tapping the gas and brake but constantly feathering the accelerator to maintain a perfectly constant speed up and down hills.

The Muscle: Electric Heating Elements

Modern furnaces abandoned combustion for a reason. Electric heating elements made from materials like graphite, molybdenum, or tungsten offer clean, predictable, and instantly adjustable power.

Unlike a gas flame, which has inherent fluctuations, the energy output of an electric element can be minutely controlled by the PID system. This direct control over power input is fundamental to achieving a stable thermal environment.

The Senses: High-Accuracy Thermocouples

A control system is only as good as the information it receives. High-accuracy thermocouples act as the furnace's nerve endings, providing constant, reliable temperature readings to the PID controller.

The placement and quality of these sensors are critical. They provide the real-time feedback necessary for the controller to make its precise calculations and adjustments, completing the feedback loop.

From Control to Uniformity: Achieving a Stable Environment

A perfect controller is not enough if the heat isn't distributed evenly. The physical design of the furnace is just as important for ensuring that the temperature at one end of the chamber is the same as the other.

The Importance of Chamber Design

High-grade ceramic fiber insulation and carefully engineered chamber geometry are crucial. This design minimizes heat loss to the outside environment and prevents the formation of hot or cold spots within the chamber. A well-insulated, sealed chamber creates a stable environment that is easier for the PID system to manage effectively.

Multi-Zone Heating for Advanced Applications

For larger furnaces or processes requiring exceptionally tight tolerances, multi-zone heating is employed. These systems divide the furnace into several distinct heating areas.

Each zone is equipped with its own heating elements and thermocouple, all governed by the central controller. This allows the system to apply more or less power to specific areas, ensuring a validated temperature uniformity (e.g., ±1°C to ±5°C) across a large or complex workload.

Understanding the Trade-offs and Limitations

While modern systems are incredibly powerful, they are not magic. Understanding their operational boundaries is key to achieving reliable results.

PID Tuning is Critical

A PID controller must be "tuned" to the specific furnace it's in. A poorly tuned controller can cause the temperature to oscillate wildly around the setpoint or take far too long to stabilize. Professional calibration ensures the P, I, and D values are optimized for the furnace's thermal characteristics.

Physical Constraints Still Apply

Even the best controller cannot defy physics. The maximum heating and cooling rates (ramp rates) are limited by the furnace's power output, its mass, and the thermal properties of the insulation and the sample itself.

Sensor Placement Matters

A thermocouple provides the temperature for its exact location. If your sample is large or dense, the temperature in the center of the sample may lag behind the chamber's air temperature. For critical processes, placing a secondary thermocouple on or inside the part being treated is essential for true process validation.

Making the Right Choice for Your Process

The level of precision you require depends directly on your application's sensitivity to thermal variation.

- If your primary focus is general ashing, debinding, or simple heat treatments: A standard furnace with a well-calibrated single-zone PID controller is more than sufficient.

- If your primary focus is materials research or aerospace/medical components: You need a system with documented temperature uniformity (e.g., ±5°C or better) and potentially multi-zone heating.

- If your primary focus is process repeatability and data logging: Prioritize models with advanced digital controllers that allow for programming complex temperature profiles and exporting data for quality control.

Ultimately, understanding that precision comes from the intelligent synergy between control systems and physical design empowers you to select a furnace that truly meets your technical requirements.

Summary Table:

| Component | Role in Precision Control | Key Features |

|---|---|---|

| PID Controller | Brain of the system, adjusts power in real-time | Uses P, I, D terms to eliminate deviations and prevent overshooting |

| Electric Heating Elements | Muscle, provides clean, adjustable heat | Made from materials like graphite or molybdenum for predictable output |

| Thermocouples | Senses temperature, provides feedback | High-accuracy sensors placed strategically for reliable readings |

| Chamber Design | Ensures heat uniformity | Uses ceramic fiber insulation and sealed geometry to prevent hot/cold spots |

| Multi-Zone Heating | Enhances uniformity in large furnaces | Separate zones with individual controls for tight tolerances (±1°C to ±5°C) |

Upgrade your laboratory with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we offer advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures your unique experimental needs are met with superior temperature control and uniformity. Contact us today to discuss how our furnaces can enhance your process efficiency and reliability!

Visual Guide

Related Products

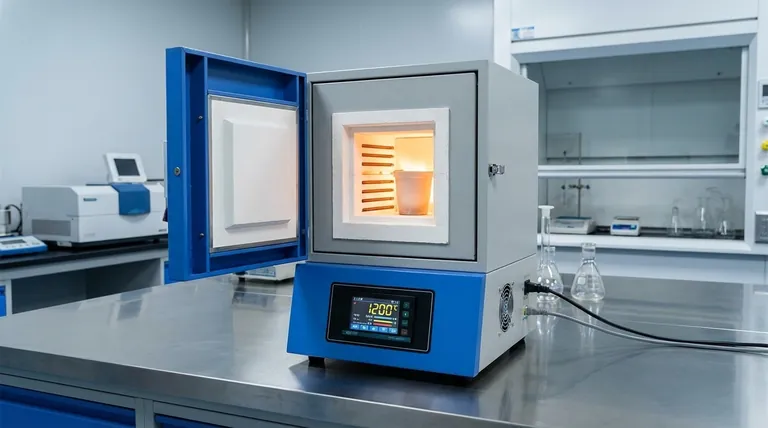

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO