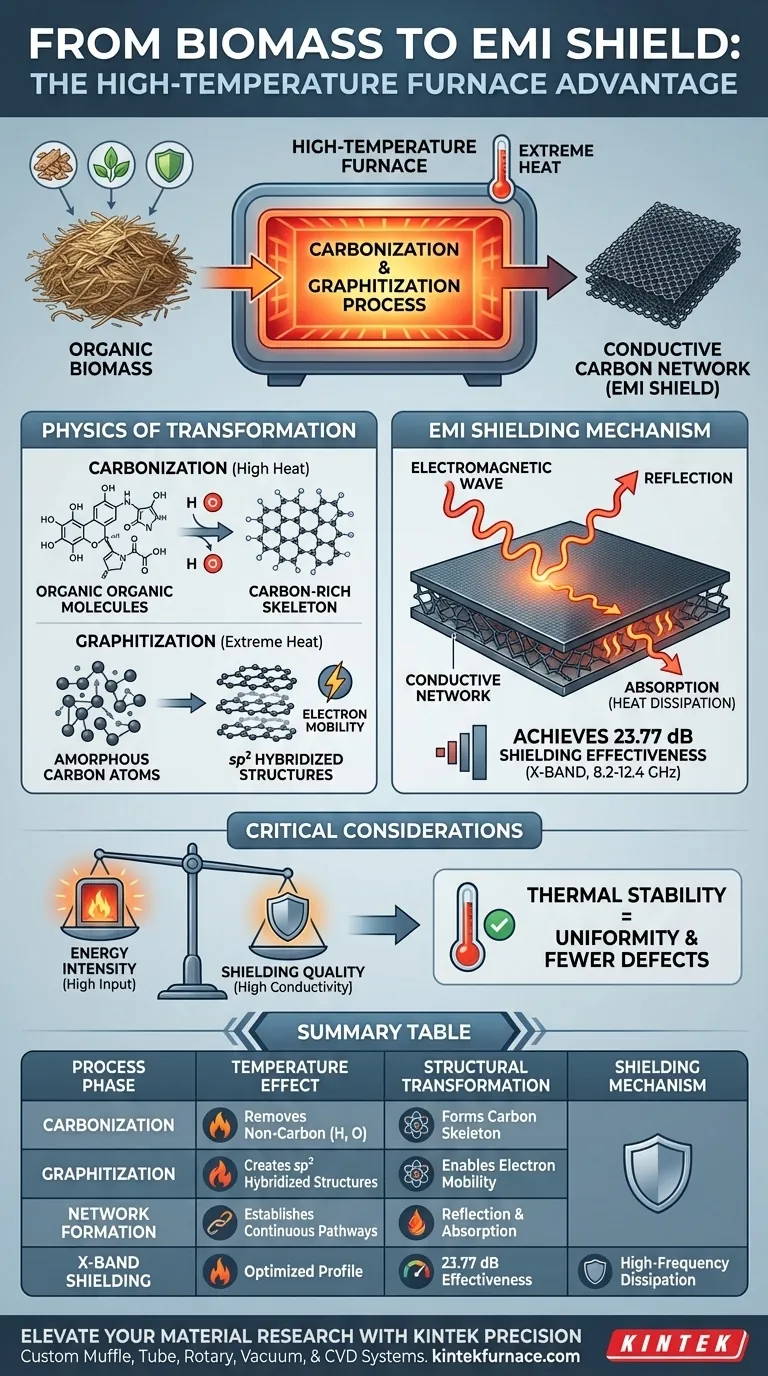

High-temperature furnace processing serves as the fundamental architect for converting organic biomass into effective electromagnetic interference (EMI) shielding materials. By subjecting biomass to extreme heat, the furnace drives carbonization and graphitization, transforming a naturally insulating material into a highly conductive carbon network capable of blocking electromagnetic signals.

Core Takeaway The furnace is not merely a heating element; it is a structural tool that forces carbon atoms to rearrange into an electrically conductive $sp^2$ hybridized structure. Without this specific high-temperature transformation, biomass lacks the conductivity required to absorb or reflect electromagnetic waves effectively.

The Physics of Structural Transformation

Carbonization and Graphitization

The primary function of the high-temperature furnace is to induce deep chemical changes within the biomass.

Through carbonization, the heat strips away non-carbon elements like hydrogen and oxygen.

This leaves behind a carbon-rich skeleton, which is the precursor to a functional shielding material.

Formation of $sp^2$ Hybridized Structures

Heat alone is not enough; the specific arrangement of atoms matters.

High temperatures facilitate the formation of an $sp^2$ hybridized carbon structure.

This specific atomic configuration allows electrons to move freely, creating the electrical conductivity necessary for EMI shielding.

Creating a Conductive Network

For a film to act as a shield, it cannot have isolated conductive patches.

The furnace ensures the formation of a continuous conductive network throughout the material.

This continuity is essential for intercepting and dissipating electromagnetic energy.

Performance and Shielding Effectiveness

Dual-Mechanism Defense

The conductive structure created by the furnace utilizes two distinct methods to stop interference.

First, it reflects incoming electromagnetic waves off the surface.

Second, it absorbs energy as it passes through the material, dissipating it as heat.

Quantifiable Results in the X-Band

The impact of this processing is measurable and significant.

Research indicates that biomass films processed in this manner can achieve a shielding effectiveness of 23.77 dB.

This performance is specifically noted in the X-band frequency range (8.2–12.4 GHz), a critical spectrum for telecommunications.

Critical Considerations and Trade-offs

The Necessity of Thermal Stability

While high heat is the catalyst, stability is the control variable.

As noted in broader material processing contexts, high-temperature furnaces provide the stable environment required for precise physicochemical reactions.

Inconsistent temperatures can lead to structural defects, reducing the uniformity and effectiveness of the conductive network.

Energy Intensity vs. Material Performance

There is an inherent trade-off between energy consumption and shielding quality.

Achieving the graphitized state required for high conductivity demands significant energy input.

However, attempting to process at lower temperatures to save energy will result in a material that is insufficiently conductive for EMI applications.

Making the Right Choice for Your Goal

When developing biomass-based EMI shields, the furnace parameters define your final product's capability.

- If your primary focus is Maximum Shielding Effectiveness: Prioritize higher temperatures to maximize graphitization and the density of the $sp^2$ carbon network.

- If your primary focus is Material Consistency: Ensure your furnace maintains a rigorously stable environment to prevent defects in the conductive network.

The furnace is the decisive factor that elevates biomass from agricultural waste to a functional electronic component.

Summary Table:

| Process Phase | Temperature Effect | Structural Transformation | Shielding Mechanism |

|---|---|---|---|

| Carbonization | High Heat | Removes non-carbon elements (H, O) | Forms carbon-rich skeleton |

| Graphitization | Extreme Heat | Creates $sp^2$ hybridized structures | Enables electron mobility |

| Network Formation | Controlled Cooling | Establishes continuous pathways | Reflection & Absorption |

| X-Band Shielding | Optimized Profile | Achievement of 23.77 dB effectiveness | High-frequency dissipation |

Elevate Your Material Research with KINTEK Precision

Transforming raw biomass into high-performance EMI shielding requires more than just heat; it requires absolute thermal precision. At KINTEK, we understand that the density of your $sp^2$ carbon network depends on the stability of your processing environment.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are scaling up carbonization or refining graphitization, our lab high-temp furnaces are fully customizable to meet your unique research needs.

Ready to achieve superior conductivity and 23.77 dB+ shielding effectiveness? Contact us today to find your custom furnace solution!

Visual Guide

References

- Junchao Ren, Qingfa Zhang. All‐Biomass Nanocomposite Films via Facile and Sustainable Design Procedure for Thermal Management and Electromagnetic Interference Shielding. DOI: 10.1002/advs.202510372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a constant temperature heating device influence rare earth leaching? Boost Extraction Efficiency to 95.72%

- Why is precise temperature control in an aging oven critical for ZK61 alloys? Master the 175°C Pre-aging Threshold

- What are the advantages of using a vacuum drying oven for magnesium slag? Preserving Sample Integrity

- How does a vacuum oven contribute to the performance of composite electrode slurries? Enhance Battery Life & Stability

- Why use liquid nitrogen freezing & vacuum freeze-drying for cement and biomass hydration? Preserve Microstructure Now

- What are the technical functions of carrier gases in VTD? Master Vapor Transport Deposition Control

- Why is zone refining essential for alkali halide crystals? Achieve Pure Intrinsic Luminescence Data

- What is the role of a dedicated bias power supply in low-pressure plasma nitriding? Master Ion Acceleration Control