Zone refining is essential for preparing alkali halide crystals because it provides the extreme level of purity required to distinguish genuine scientific data from background noise. By exploiting the physical differences in how impurities behave in solid versus liquid states, this process systematically purges contaminants that would otherwise compromise the study of intrinsic luminescence.

Intrinsic luminescence research relies on observing delicate exciton decay processes without interference. Zone refining ensures data integrity by driving heterovalent ions and organic impurities to the ends of the material rod, ensuring observed results are derived strictly from intended dopants.

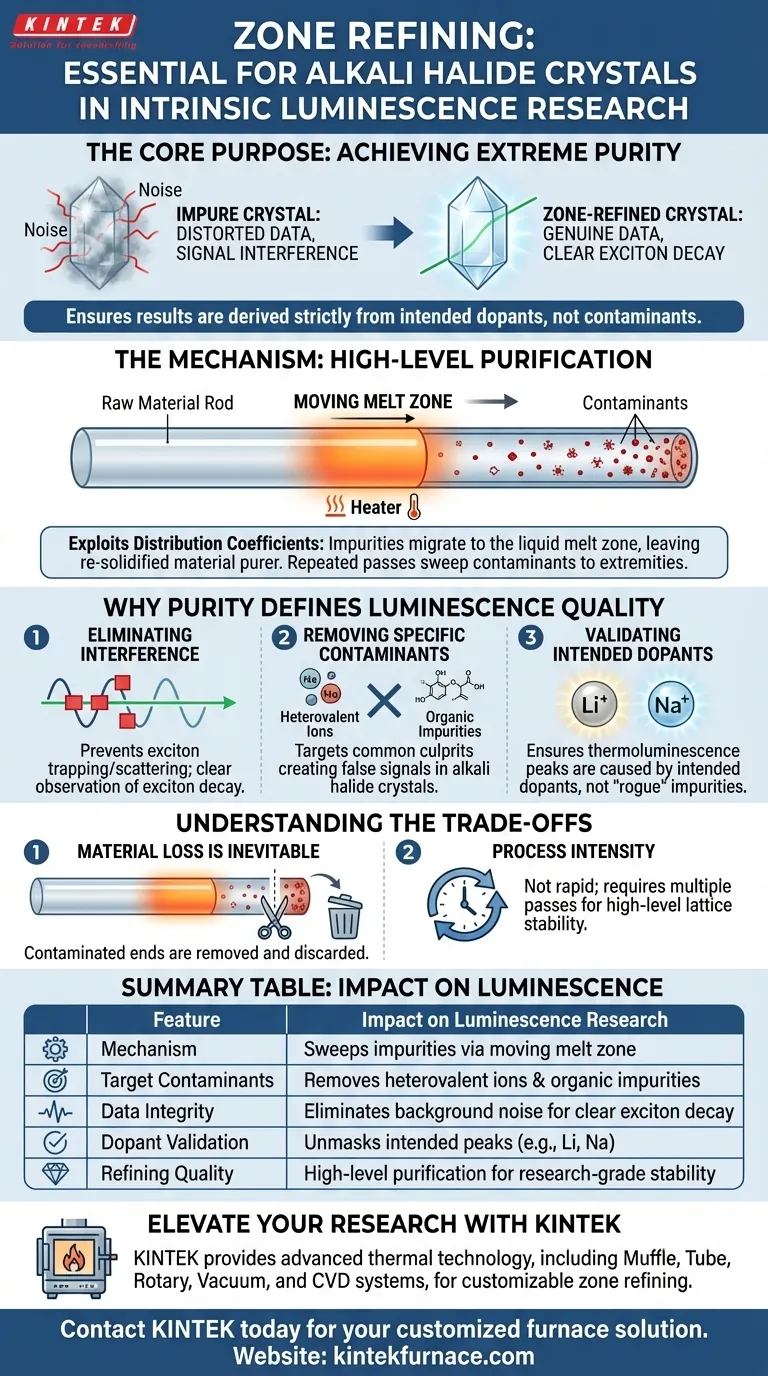

The Mechanism of High-Level Purification

Exploiting Distribution Coefficients

The core principle of zone refining lies in the distribution coefficient. This physical property dictates that impurities have different solubilities in the liquid phase compared to the solid phase of the same material.

When a section of the raw material is melted, impurities naturally migrate into the liquid zone. As the material re-solidifies behind the moving melt zone, it crystallizes in a purer form.

The Moving Melt Zone Technique

To achieve the necessary purity, a heater moves a "melt zone" through the raw material rod. This is not a one-time event; the process is repeated multiple times.

With each pass, the melt zone carries the dissolved impurities further along the rod. This effectively sweeps contaminants from the bulk of the material toward the extremities.

Why Purity Defines Luminescence Quality

Eliminating Signal Interference

In the study of intrinsic luminescence, researchers are observing exciton decay. This is a subtle quantum process that emits light.

If uncontrolled impurities are present, they can trap or scatter these excitons. This interference distorts the data, making it impossible to tell if a signal is a genuine material property or an artifact of contamination.

Removing Specific Contaminants

The zone refining process specifically targets heterovalent ions and organic impurities. These are the most common culprits for creating false signals in alkali halide crystals.

By concentrating these specific contaminants at the very ends of the rod, the central portion remains pristine.

Validating Intended Dopants

Research often involves doping crystals with specific elements, such as lithium (Li) or sodium (Na) ions, to study their specific thermoluminescence peaks.

Without zone refining, "rogue" impurities could mimic or mask the signals from these intended dopants. Refining ensures that any observed peak is undeniably caused by the specific dopant being studied.

Understanding the Trade-offs

Material Loss is Inevitable

Zone refining is a subtractive process. Because impurities are driven to the ends of the rod, those ends become highly contaminated and must be cut off and discarded.

Process Intensity

This is not a rapid purification method. It requires multiple passes of the melt zone to achieve the high-level purification required for research standards. It prioritizes quality of the crystal lattice over speed of production.

Ensuring Data Integrity in Crystal Research

To ensure your research into intrinsic luminescence yields publishable, reproducible results, you must prioritize the quality of your starting material.

- If your primary focus is baseline accuracy: Prioritize zone refining to remove organic impurities that create unpredictable background noise during exciton decay.

- If your primary focus is dopant study (Li/Na): Use zone-refined materials to guarantee that thermoluminescence peaks are caused by your specific ions, not random heterovalent contaminants.

The reliability of your luminescence data is directly proportional to the rigor of your purification process.

Summary Table:

| Feature | Impact on Luminescence Research |

|---|---|

| Mechanism | Exploits distribution coefficients to sweep impurities into a moving melt zone |

| Target Contaminants | Effectively removes heterovalent ions and organic impurities |

| Data Integrity | Eliminates background noise to allow clear observation of exciton decay |

| Dopant Validation | Ensures thermoluminescence peaks (e.g., Li, Na) are not masked by "rogue" ions |

| Refining Quality | High-level purification through multiple passes for research-grade lattice stability |

Elevate Your Research with Ultra-Pure Materials

Precise data in intrinsic luminescence research begins with the absolute purity of your crystal substrates. KINTEK provides the advanced thermal technology necessary to achieve these rigorous standards. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature lab furnaces—all fully customizable to meet your unique zone refining and crystal growth requirements.

Don't let impurities compromise your scientific integrity. Contact KINTEK today to discuss your customized furnace solution and ensure your results are driven by science, not contamination.

Visual Guide

References

- K. Shunkeyev, Zarina Serikkaliyeva. The Nature of High-Temperature Peaks of Thermally Stimulated Luminescence in NaCl:Li and KCl:Na Crystals. DOI: 10.3390/cryst15010067

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a high vacuum deposition system ensure thin film quality? Purity Through Advanced Pumping

- What is the function of a forced air drying oven in the dehydration of acid-washed zeolite? Ensure Sample Purity.

- What roles does a laboratory oven play in biochar production? Enhance Efficiency and Accuracy in Thermal Processing

- What is the primary role of the Thermal Oxidation (TO) process in Ti-6Al-4V ELI alloy? Enhancing Hardness and Wear

- How does a graphite furnace work? Achieve Ultra-Trace Element Analysis

- What role does an industrial electric furnace play in PAI? Master Thermal Preparation for Metal Matrix Composites

- Why is a precision electric heating reactor used for ozone treatment of porous graphene? Unlock Angstrom-Scale Accuracy

- What is the primary function of an electric furnace in PBG melting? Expert Guide to Thermal Homogeneity