The primary purpose of applying a carbon coating to the inner wall of quartz tubes is to act as a critical barrier between the molten bismuth telluride alloy and the silica (SiO2) container. This coating prevents the molten material from wetting or chemically reacting with the tube, which safeguards the vessel against corrosion and ensures the crystal can be removed intact.

By isolating the melt from the quartz wall, carbon coating prevents chemical adhesion and container failure. This simple step preserves the precise stoichiometric ratio of the material and allows for smooth demolding without damaging the crystal or the ampoule.

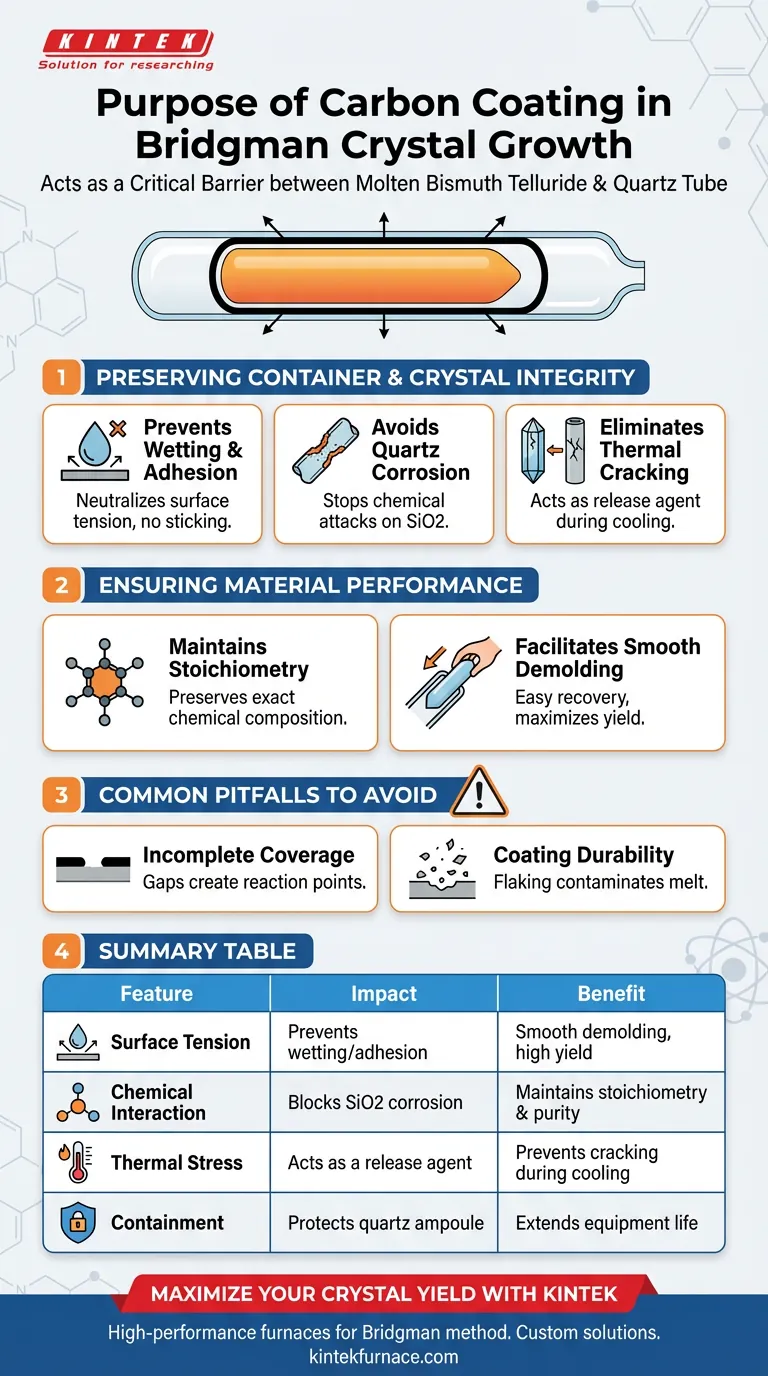

Preserving Container and Crystal Integrity

The Bridgman method relies on precise thermal control and containment. Without a protective interface, the interaction between bismuth telluride and quartz compromises the entire growth process.

Preventing Wetting and Adhesion

Molten bismuth telluride has a natural tendency to wet (adhere to) silica glass surfaces.

A carbon layer effectively neutralizes this surface tension interaction. By preventing the melt from sticking to the wall, the material behaves as a contained liquid rather than a bonded coating.

Avoiding Quartz Corrosion

Direct contact between the alloy and the tube can lead to chemical attacks on the silica.

This reaction causes corrosion of the quartz tube, weakening its structural integrity. A carbon barrier creates an inert shield that stops this chemical degradation at the source.

Eliminating Thermal Cracking

When an alloy bonds to the quartz wall, the cooling phase becomes dangerous.

As the crystal and the tube contract at different rates, the adhesion creates immense stress. This leads to cracking in the quartz tube or, worse, the crystal itself. Carbon coating acts as a release agent, preventing this stress accumulation.

Ensuring Material Performance

The quality of a thermoelectric material is defined by its chemical composition. The carbon coating plays a vital role in maintaining this chemistry.

Maintaining Stoichiometry

Bismuth telluride requires a precise stoichiometric ratio to function effectively as a thermoelectric material.

If the melt reacts with the quartz, the chemical composition shifts. Elements may be lost to the reaction or impurities from the silica may enter the melt. The carbon coating ensures the melt remains chemically isolated, preserving the exact formulation required.

Facilitating Smooth Demolding

Recovery of the crystal is the final, critical step.

Because the carbon prevents wetting, the solidified crystal does not bond to the ampoule. This allows for smooth demolding, maximizing the yield and reducing the risk of mechanically damaging the crystal during extraction.

Common Pitfalls to Avoid

While carbon coating is standard practice, understanding the risks of failure is essential for consistent results.

Incomplete Coverage

The protective benefits rely entirely on a continuous, unbroken layer.

Any gap or scratch in the carbon coating creates a nucleation point for reaction. The molten alloy will attack the exposed silica, leading to localized sticking and potential tube failure even if 99% of the tube is coated.

Coating Durability

The coating must withstand the duration of the growth cycle without flaking.

If the carbon layer detaches into the melt, it can introduce particulate inclusions. While carbon is chemically inert relative to the reaction with quartz, physical inclusions can disrupt the single-crystal structure.

Making the Right Choice for Your Growth Process

The application of carbon is not just a safety measure; it is a quality control necessity.

- If your primary focus is Crystal Yield: Prioritize the uniformity of the coating to ensure the ingot creates no mechanical bonds with the wall, allowing for effortless extraction.

- If your primary focus is Material Purity: View the coating as a chemical seal that locks the stoichiometry in place and prevents silica contamination.

A consistent, high-quality carbon coating is the single most effective variable for ensuring both the survival of your equipment and the thermoelectric efficiency of your final product.

Summary Table:

| Feature | Impact of Carbon Coating | Benefit to Crystal Growth |

|---|---|---|

| Surface Tension | Prevents wetting/adhesion | Smooth demolding and high crystal yield |

| Chemical Interaction | Blocks silica (SiO2) corrosion | Maintains precise stoichiometry and purity |

| Thermal Stress | Acts as a release agent | Prevents cracking during cooling phase |

| Containment | Protects quartz ampoule | Extends equipment life and prevents failure |

Maximize Your Crystal Yield with KINTEK

Don't let container failure or material contamination compromise your research. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of the Bridgman method and beyond.

Our lab high-temperature furnaces provide the precision and reliability needed to maintain the integrity of your bismuth telluride-based crystals. Contact us today to find your custom solution!

Visual Guide

References

- Hung‐Wei Chen, Hsin‐Jay Wu. Dilute Sb Doping Yields Softer <i>p</i>‐Type Bi<sub>2</sub>Te<sub>3</sub> Thermoelectrics. DOI: 10.1002/aelm.202300793

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is a tube furnace and its main characteristics? Discover Precision Heating for Your Lab

- What is the primary purpose of using a Quartz Tube Furnace for MoS2 annealing? Unlock High Electrical Performance

- Why is a specific nitrogen flow rate necessary within a tube furnace during the carbonization of PVDF?

- How does an industrial tube furnace facilitate the pack cementation process? Master Precision Diffusion Coatings

- How does oxygen atmosphere treatment in a tube furnace affect titania nanotubes? Optimize Your Nanostructure Performance

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- What are the possible configurations of heated sections in a High Temperature Tube Furnace? Choose the Right Setup for Your Process

- What types of heating mechanisms are employed in drop tube furnaces? Choose Between Resistive and Induction Heating