At its core, a tube furnace is a high-temperature heating device built around a cylindrical tube. Heating elements surround this central tube, allowing it to achieve highly uniform temperatures for processing samples placed inside. Its design makes it ideal for applications requiring not only precise heat but also strict control over the atmospheric environment.

The essential value of a tube furnace is not merely its ability to get hot, but its capacity to create an isolated, precisely controlled micro-environment. This makes it indispensable for material synthesis and thermal processes where temperature uniformity and atmospheric purity are critical for success.

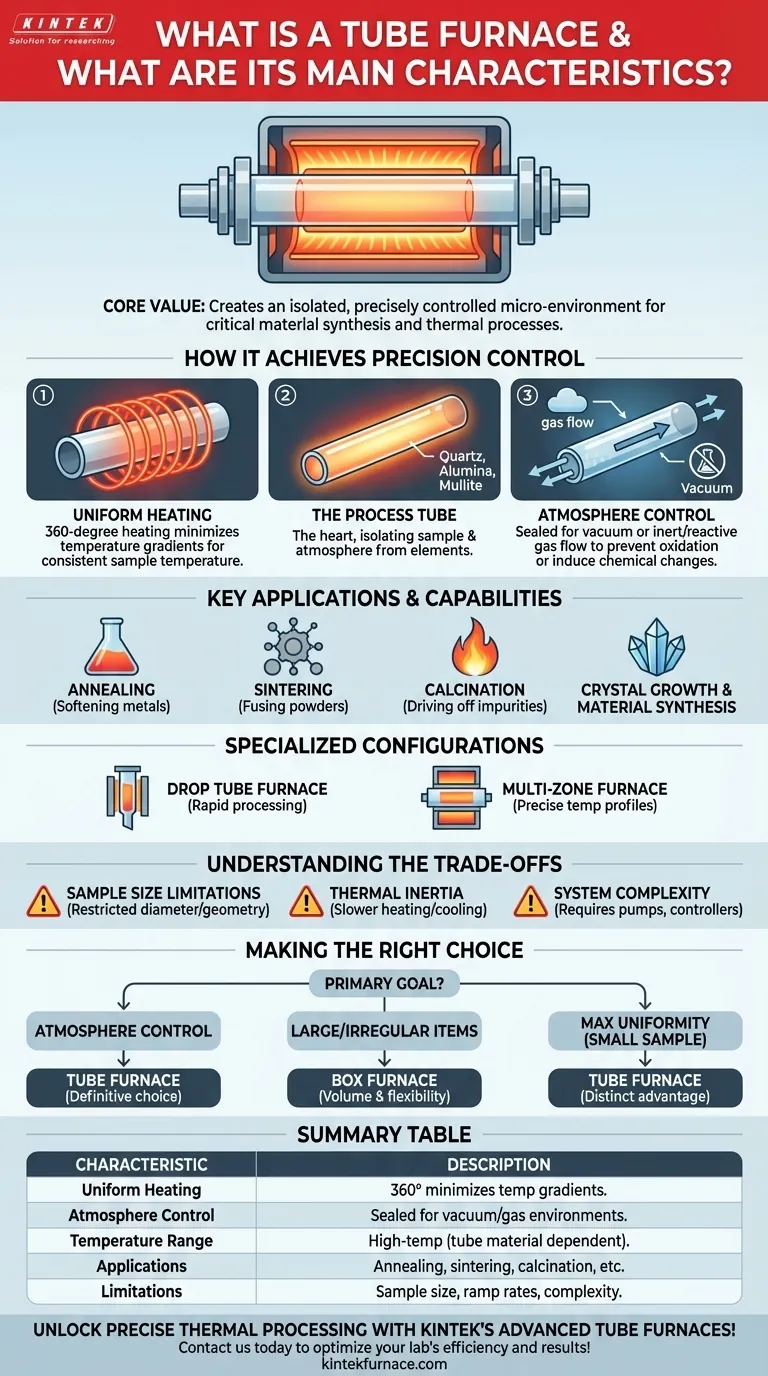

How a Tube Furnace Achieves Precision Control

A standard oven or box furnace heats a large, open chamber. A tube furnace operates on a fundamentally different principle, focusing all its energy on a small, contained volume to achieve a much higher degree of control.

The Principle of Uniform Heating

The defining feature is its cylindrical geometry. Heating elements are positioned to encircle the process tube, radiating heat inward from all sides simultaneously.

This 360-degree heating minimizes temperature gradients, ensuring that the sample experiences a consistent temperature across its entire length and volume. This uniformity is critical for processes like crystal growth and materials sintering.

The Central Role of the Process Tube

The tube itself is the heart of the furnace. It contains both the sample and the desired atmosphere, isolating them from the outside environment and the heating elements.

These tubes are typically made from materials like quartz, alumina, or mullite, chosen based on the required maximum temperature and chemical compatibility with the sample and process gases.

Achieving Precise Atmosphere Control

Perhaps the most significant advantage is the ability to control the atmosphere. The ends of the process tube can be sealed with flanges, allowing a vacuum to be pulled or specific gases to be flowed through it.

This enables processes to be conducted in inert atmospheres (like argon or nitrogen) to prevent oxidation, or in reactive gas atmospheres to induce specific chemical changes in the material.

Key Applications and Capabilities

The combination of uniform heat and atmosphere control makes the tube furnace a versatile tool in both research laboratories and specialized industrial settings.

High-Temperature Synthesis and Treatment

Tube furnaces are workhorses for a wide range of thermal processes. Common applications include annealing (softening metals), sintering (fusing powders into a solid), and calcination (heating to drive off impurities).

They are routinely used for heat-treating metal parts, growing crystals from a melt, and synthesizing advanced ceramic or composite materials.

Specialized Configurations

The basic design can be adapted for specific needs. A drop tube furnace, for example, is a vertical tube furnace where materials (often powders) are dropped through the hot zone for rapid thermal processing.

Other variations include multi-zone furnaces with independent heating elements along the tube's length, allowing for precise temperature profiles to be created.

Understanding the Trade-offs

While powerful, the tube furnace is a specialized tool with specific limitations that make it unsuitable for certain tasks.

Inherent Sample Size Limitations

The most obvious trade-off is sample size. The diameter of the process tube inherently restricts the dimensions and geometry of the object you can heat. For large or bulky components, a box or chamber furnace is a more practical choice.

Thermal Inertia and Ramp Rates

Heating and cooling the ceramic tube and insulation can be a slow process. While a tube furnace provides excellent temperature stability once at the setpoint, it may not be ideal for applications requiring extremely rapid heating or cooling cycles unless specifically designed for that purpose.

System Complexity

A simple tube furnace is straightforward, but a complete system for high-purity work is not. Adding gas flow controllers, vacuum pumps, and specialized flanges increases the cost and operational complexity compared to a basic box furnace.

Making the Right Choice for Your Application

Selecting the correct heating equipment depends entirely on your primary experimental or production goal.

- If your primary focus is atmosphere control: The sealed environment of a tube furnace is the definitive choice for any process requiring an inert, reactive, or vacuum atmosphere.

- If your primary focus is processing large or irregularly shaped items: A box furnace offers the volume and flexibility that a tube furnace cannot.

- If your primary focus is maximum temperature uniformity on a small sample: The cylindrical heating geometry of a tube furnace offers a distinct advantage over most other furnace types.

Understanding these core principles allows you to select the precise tool needed to achieve reliable and repeatable results in your work.

Summary Table:

| Characteristic | Description |

|---|---|

| Uniform Heating | 360-degree heating minimizes temperature gradients for consistent sample processing. |

| Atmosphere Control | Sealed tube allows vacuum or gas flow for inert or reactive environments. |

| Temperature Range | High-temperature capabilities, dependent on tube material (e.g., quartz, alumina). |

| Applications | Annealing, sintering, calcination, and material synthesis in research and industry. |

| Limitations | Sample size constraints, slower ramp rates, and increased system complexity. |

Unlock precise thermal processing with KINTEK's advanced tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is enhanced by strong deep customization to meet your unique experimental needs. Contact us today to discuss how we can optimize your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency