The primary purpose of utilizing a Quartz Tube Furnace for annealing Molybdenum Disulfide (MoS2) thin films is to facilitate thermal recrystallization within a controlled, high-temperature environment.

By subjecting the material to temperatures around 600°C, the furnace transforms the thin film from an amorphous or weakly crystalline state into a highly ordered structure. This process enables atomic rearrangement, which is essential for stabilizing the material phase and significantly optimizing its electrical properties.

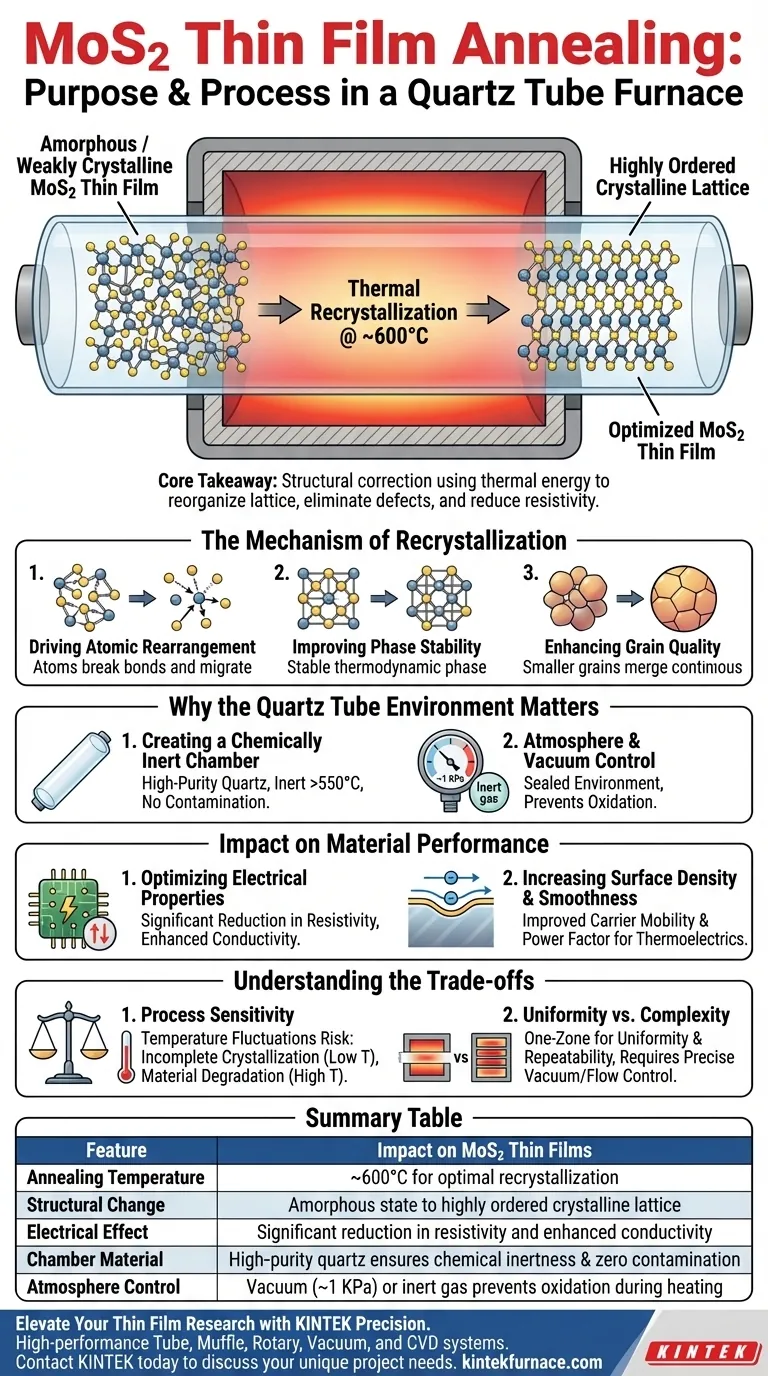

Core Takeaway Annealing MoS2 in a Quartz Tube Furnace acts as a structural correction mechanism; it utilizes thermal energy to reorganize the atomic lattice, thereby eliminating defects and reducing resistivity to unlock the material's full electronic potential.

The Mechanism of Recrystallization

Driving Atomic Rearrangement

The fundamental goal of this annealing process is to input enough thermal energy to break the bonds of a disordered state.

At approximately 600°C, the molybdenum and sulfur atoms gain sufficient energy to migrate and realign. This transforms the film from a chaotic, amorphous structure into a coherent, crystalline lattice.

Improving Phase Stability

As the atoms realign, the material achieves a more thermodynamically stable phase.

This stability is critical for ensuring that the physical properties of the MoS2 film remain consistent over time and under operating conditions.

Enhancing Grain Quality

The thermal treatment drives grain growth, merging smaller, fragmented grains into larger, continuous structures.

This reduction in grain boundaries minimizes the scattering of charge carriers, which is a primary factor in improving the material's overall performance.

Why the Quartz Tube Environment Matters

Creating a Chemically Inert Chamber

A high-purity quartz tube serves as the core reaction chamber because it is chemically inert.

It withstands temperatures exceeding 550°C without reacting with the sulfur vapor or the molybdenum layer. This prevents impurities from the chamber walls from contaminating the delicate thin film during processing.

Atmosphere and Vacuum Control

The tube furnace allows for the maintenance of a specific vacuum level (typically around 1 KPa) or an inert gas flow.

This sealed environment excludes atmospheric oxygen, which is vital because oxygen can degrade the film during the high-heat phase. The secure seal ensures the sulfurization reaction occurs without oxidative interference.

Impact on Material Performance

Optimizing Electrical Properties

The most tangible result of atomic rearrangement is a significant reduction in resistivity.

By organizing the lattice and removing structural defects, the annealing process creates a more efficient path for electron flow. This directly enhances the electrical conductivity of the MoS2 film.

Increasing Surface Density and Smoothness

Thermal processing eliminates irregular microstructures on the film's surface.

As the film anneals, it becomes denser and smoother. This microscopic evolution improves carrier mobility and the power factor, key components for thermoelectric applications.

Understanding the Trade-offs

Process Sensitivity

While annealing improves quality, the process is highly sensitive to temperature fluctuations. Deviating from the optimal 600°C range can lead to incomplete crystallization (if too low) or material degradation (if too high).

Uniformity vs. Complexity

Using a one-zone tube furnace generally provides superior uniformity and repeatability for MoS2 compared to multi-zone configurations.

However, achieving this uniformity requires precise optimization of process conditions. Inadequate control over the vacuum pressure or gas flow can result in uneven sulfurization across large-area films.

Making the Right Choice for Your Project

The specific configuration of your annealing process should depend on the final application of the MoS2 film.

- If your primary focus is Electrical Conductivity: Prioritize the 600°C temperature stability to maximize recrystallization and minimize resistivity.

- If your primary focus is Large-Area Uniformity: Utilize a one-zone furnace configuration to ensure consistent sulfurization and film quality across the entire substrate.

- If your primary focus is Thermoelectric Performance: Concentrate on extended annealing times to maximize grain growth and surface smoothness for improved carrier mobility.

Success in annealing MoS2 relies not just on reaching high temperatures, but on maintaining a pristine, oxygen-free environment that allows the material to rebuild itself at the atomic level.

Summary Table:

| Feature | Impact on MoS2 Thin Films |

|---|---|

| Annealing Temperature | ~600°C for optimal recrystallization |

| Structural Change | Amorphous state to highly ordered crystalline lattice |

| Electrical Effect | Significant reduction in resistivity and enhanced conductivity |

| Chamber Material | High-purity quartz ensures chemical inertness & zero contamination |

| Atmosphere Control | Vacuum (~1 KPa) or inert gas prevents oxidation during heating |

Elevate Your Thin Film Research with KINTEK Precision

Achieving the perfect crystalline structure in MoS2 thin films requires absolute control over temperature and atmosphere. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of material science.

Whether you need a single-zone tube furnace for superior uniformity or a customized vacuum system for sensitive sulfurization processes, our lab high-temp furnaces provide the stability and purity your research deserves.

Ready to optimize your annealing process? Contact KINTEK today to discuss your unique project needs!

Visual Guide

References

- Irasani Rahayu, Melania Suweni Muntini. Effect of Annealing Techniques on the Thermoelectric Properties of Molybdenum Disulfide Thin Films Prepared by RF Sputtering. DOI: 10.1088/1742-6596/3139/1/012035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is heat transferred to the sample in a multi gradient experimental tube furnace? Master Precise Heat Control

- Why choose a vertical tube furnace over a horizontal tube furnace? Achieve Superior Uniformity and Purity

- How does a tube furnace contribute to the ammonia reduction annealing process for (NiZnMg)MoN catalysts? Optimize Phase Transitions

- What role does a laboratory tube furnace play in geological and mineralogical research? Unlock Earth's Secrets with Precision

- Why is a tube annealing furnace used for SiC hydrogenation? Unlock Pure Atomic Surfaces for Superior Crystal Bonding

- Why is a stable nitrogen flow required in a tube furnace for hydrochar carbonization? Ensure High-Carbon Purity

- How is the silver contamination inside a quartz tube addressed? 1000°C Thermal Cleaning for Pure CVD Results

- Why is a vacuum tube furnace required for (Si/graphite/graphene)@C composite? Ensure Optimal High-Temp Performance