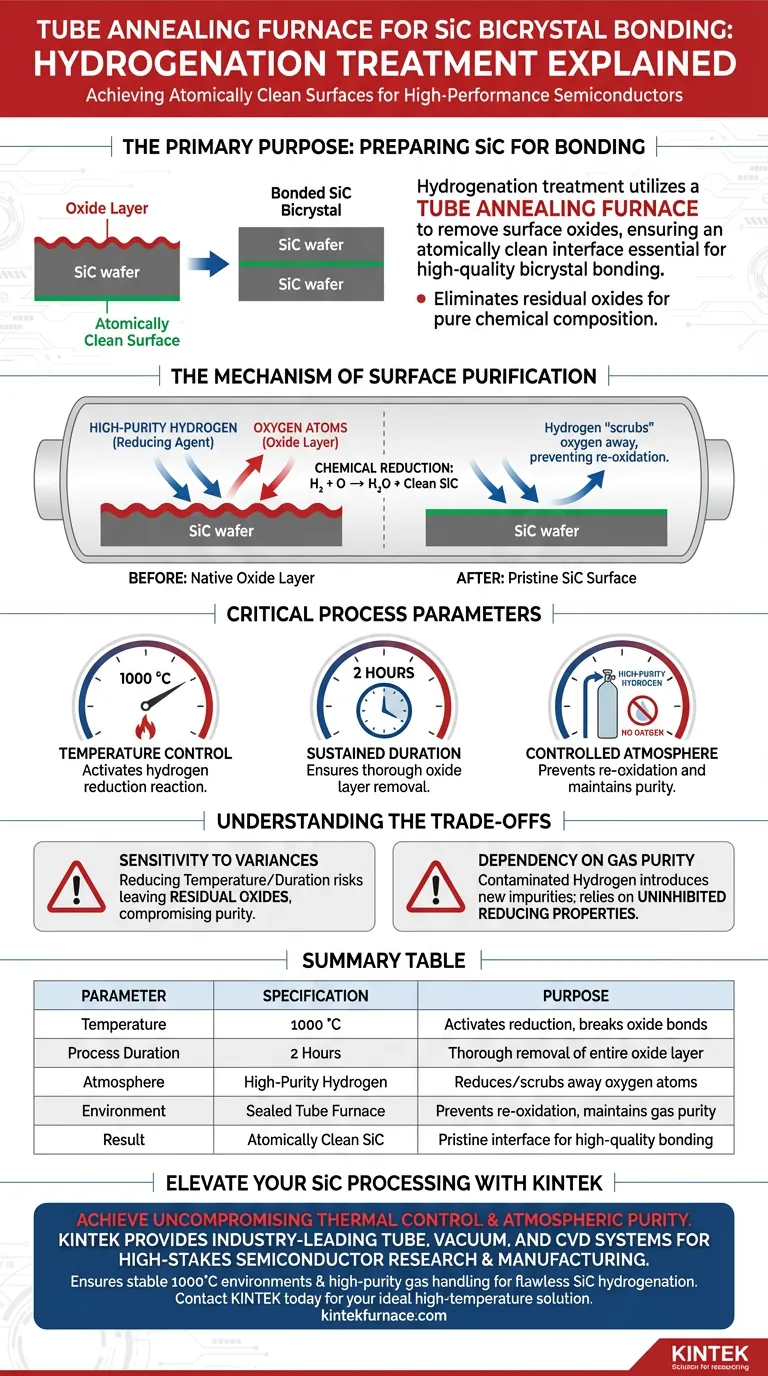

The primary purpose of utilizing a tube annealing furnace for hydrogenation treatment is to prepare Silicon Carbide (SiC) wafers for bonding by ensuring an atomically clean surface. By subjecting the wafers to a 1000 °C environment for two hours, the process leverages the reducing properties of hydrogen to completely strip away surface oxide layers.

Achieving high-quality SiC bicrystals requires an interface free of contaminants. Hydrogenation treatment eliminates residual oxides, ensuring the final bonded sample maintains a pure chemical composition essential for reliable semiconductor performance.

The Mechanism of Surface Purification

To understand why this specific furnace treatment is necessary, you must look at the chemistry occurring at the wafer's surface.

The Role of Hydrogen as a Reducing Agent

The central mechanism at work is chemical reduction.

Hydrogen, when heated to high temperatures, becomes highly reactive. It actively bonds with the oxygen atoms present in the oxide layer on the SiC surface. This reaction effectively "scrubs" the oxygen away, leaving behind pure Silicon Carbide.

Eliminating the Oxide Barrier

Silicon Carbide naturally forms a native oxide layer when exposed to air.

If this layer is not removed, it acts as a contaminant between the two crystals during bonding. The tube furnace ensures that this oxide layer is completely removed, creating a pristine interface. This allows the two crystals to bond directly without an insulating or interfering oxide film.

Critical Process Parameters

The success of this treatment relies on strict adherence to specific environmental conditions provided by the tube furnace.

Precise Temperature Control

The process demands a high temperature of 1000 °C.

This thermal energy is required to activate the hydrogen reduction reaction. Without sufficient heat, the hydrogen cannot effectively break the bonds of the oxide layer.

Sustained Duration

The treatment is maintained for a specific duration of two hours.

This time window ensures the reaction is thorough, penetrating and removing the entire oxide layer rather than just the surface-most atoms.

Controlled High-Purity Atmosphere

The tube annealing furnace provides a sealed, controlled environment.

It allows for the introduction of high-purity hydrogen while excluding atmospheric oxygen. This prevents re-oxidation of the surface during the cleaning process.

Understanding the Trade-offs

While effective, this process requires rigorous control to avoid failure.

Sensitivity to Process Variances

The specific parameters (1000 °C for 2 hours) are not arbitrary.

Reducing the temperature or shortening the duration risks leaving residual oxides on the surface. Even trace amounts of oxide can compromise the chemical purity of the final bicrystal sample.

Dependency on Gas Purity

The quality of the outcome is directly tied to the purity of the hydrogen gas used.

If the hydrogen source contains contaminants, the tube furnace environment will simply introduce new impurities to the wafer surface. The system relies entirely on the reducing properties of the gas being uninhibited by external pollutants.

Ensuring Success in SiC Bonding

To achieve the highest quality Silicon Carbide bicrystal samples, apply these principles to your workflow.

- If your primary focus is Interface Purity: Ensure your hydrogen source is certified high-purity to prevent introducing new contaminants during the reduction process.

- If your primary focus is Bonding Consistency: Adhere strictly to the 1000 °C and 2-hour parameters to guarantee the complete removal of the oxide layer every time.

By controlling the atmosphere and energy within the furnace, you transform a standard wafer into a chemically pure substrate ready for high-performance bonding.

Summary Table:

| Parameter | Specification | Purpose |

|---|---|---|

| Temperature | 1000 °C | Activates hydrogen reduction and breaks oxide bonds |

| Process Duration | 2 Hours | Ensures thorough removal of the entire surface oxide layer |

| Atmosphere | High-Purity Hydrogen | Acts as a reducing agent to 'scrub' away oxygen atoms |

| Environment | Sealed Tube Furnace | Prevents re-oxidation and maintains gas purity |

| Result | Atomically Clean SiC | Guarantees a pristine interface for high-quality bonding |

Elevate Your SiC Processing Precision with KINTEK

Achieving the perfect atomically clean surface requires uncompromising thermal control and atmospheric purity. KINTEK provides industry-leading, customizable Tube, Vacuum, and CVD systems designed specifically for high-stakes semiconductor research and manufacturing.

Backed by expert R&D, our furnaces ensure the stable 1000°C environments and high-purity gas handling necessary for flawless SiC hydrogenation and bicrystal bonding. Don't let residual oxides compromise your semiconductor performance—contact KINTEK today to find the ideal high-temperature solution for your lab's unique needs.

Visual Guide

References

- Jianqi Xi, Izabela Szlufarska. Coupling of radiation and grain boundary corrosion in SiC. DOI: 10.1038/s41529-024-00436-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What advanced control features do modern tube furnaces have? Precision Temperature, Atmosphere, and Data Control

- How does a tube furnace control the phase structure of copper-based chalcogenides? Master Precise Thermal Management

- How is temperature control achieved in a tube furnace? Master Precise Heating for Your Lab

- Why is a tube furnace with argon required for Ti3AlC2 sintering? Protect Your High-Purity MAX Phase Synthesis

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- What safety features are included in an atmosphere tube furnace? Essential Systems for Secure High-Temp Operations

- What technical requirements must a laboratory tube furnace meet for SOFC testing? Ensure Precise Fuel Cell Analysis

- What are the advantages of using a three-zone tube furnace? Precision Gradient Control for Fe3GeTe2 Crystal Growth