At its core, an atmosphere tube furnace is equipped with several critical safety systems. The most fundamental features are over-temperature protection to prevent overheating and automatic shutdown protocols that engage during abnormal conditions. For models using controlled atmospheres, features like gas leakage detection and flow monitoring are essential to prevent hazardous situations.

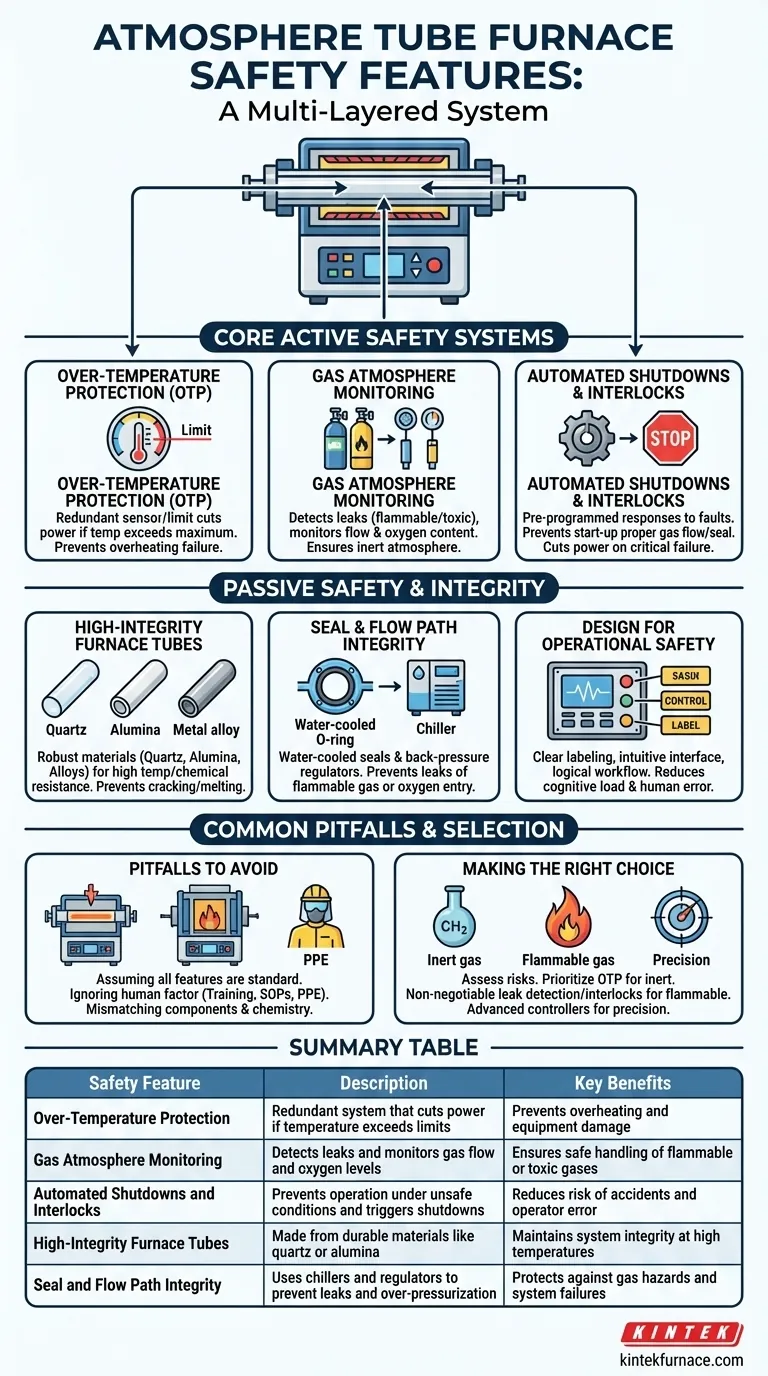

Safety in an atmosphere tube furnace is not a single feature but a multi-layered system. It combines active electronic monitoring, robust physical design, and procedural safeguards to protect the operator, the sample, and the equipment itself from the inherent risks of high temperatures and specialized gas environments.

Core Active Safety Systems

Active systems are the furnace's first line of defense, constantly monitoring operations and intervening automatically when parameters go outside of safe limits.

Over-Temperature Protection (OTP)

This is the most critical safety feature. It functions as a redundant check on the main temperature controller.

If the primary controller fails or a thermocouple breaks, the furnace could heat uncontrollably. The OTP system uses a separate sensor or a hard-coded software limit to cut power to the heating elements if the temperature exceeds a predefined maximum, preventing catastrophic failure.

Gas Atmosphere Monitoring

For a furnace designed to control its atmosphere, managing the gas is paramount for safety.

Systems may include gas leakage detectors for flammable or toxic gases. More advanced furnaces monitor oxygen content to ensure a pure inert atmosphere and may have interlocks that prevent the introduction of reactive gases until a safe temperature is reached.

Automated Shutdowns and Interlocks

These are the pre-programmed actions the furnace takes in response to a fault.

An interlock is a preventive measure; for example, the furnace may not start heating if it doesn't detect proper gas flow or if the end flanges are not sealed. An automated shutdown is a reactive measure that cuts power and may trigger an alarm if a critical failure like over-temperature is detected.

Passive Safety and System Integrity

Passive safety is built into the physical construction and material choice of the furnace. These features are designed to be inherently robust and fail-safe.

High-Integrity Furnace Tubes

The furnace tube is the barrier between the high-temperature process and the outside world. Its integrity is a non-negotiable safety requirement.

Tubes are made from materials like quartz, high-purity alumina, or heat-resistant metal alloys. Choosing the correct material for your maximum temperature and chemical environment is a critical safety decision to prevent tube cracking, melting, or chemical degradation.

Seal and Flow Path Integrity

Maintaining the controlled atmosphere requires a perfectly sealed system.

Water-cooled recirculating chillers are often used to protect the silicone or Viton O-ring seals at the tube ends. A failed seal can cause a dangerous leak of flammable gas or allow oxygen to enter the hot zone, potentially ruining a sample or causing an explosive reaction. Components like a back-pressure regulator also prevent the system from becoming over-pressurized.

Design for Operational Safety

A well-designed furnace minimizes the chance of human error.

Clear labeling, an intuitive control interface, and logical workflow are subtle but powerful safety features. They reduce the cognitive load on the operator, making it easier to follow procedures correctly and less likely to make a mistake that could compromise safety.

Common Pitfalls to Avoid

Even the best furnace can be operated unsafely. Understanding these common risks is as important as understanding the features themselves.

Assuming All Features Are Standard

Safety systems vary significantly between models and manufacturers. A basic, low-cost furnace may only have rudimentary over-temperature protection. Advanced systems for reactive gases require more sophisticated and expensive interlocks and gas sensing capabilities. Always verify the specific safety package of any furnace you consider.

The Critical Human Factor

No safety system can fully compensate for a lack of training. The furnace is just one part of a safe operating ecosystem. This ecosystem must include Standard Operating Procedures (SOPs), proper operator training, and appropriate Personal Protective Equipment (PPE).

Mismatching Components and Chemistry

A frequent cause of failure is using components improperly. This includes using a quartz tube at a temperature it can't handle, introducing a gas that reacts with the heating elements (e.g., hydrogen with Kanthal elements above ~1050°C), or failing to properly purge the system with inert gas before introducing flammable gases.

Making the Right Choice for Your Application

Select a furnace based on a clear-eyed assessment of the risks associated with your specific process.

- If your primary focus is high-temperature processing with inert gas: Prioritize robust over-temperature protection and a furnace tube material rated well above your maximum operating temperature.

- If your primary focus is working with flammable gases (e.g., Hydrogen): A system with integrated gas leakage detection, certified safety interlocks, and a thorough purging protocol is non-negotiable.

- If your primary focus is precision and sample protection: Look for advanced controllers with redundant sensors and tight monitoring of atmosphere purity to prevent costly failures.

Ultimately, viewing safety as an integrated system—not just a checklist of features—is the key to secure and successful operation.

Summary Table:

| Safety Feature | Description | Key Benefits |

|---|---|---|

| Over-Temperature Protection | Redundant system that cuts power if temperature exceeds limits | Prevents overheating and equipment damage |

| Gas Atmosphere Monitoring | Detects leaks and monitors gas flow and oxygen levels | Ensures safe handling of flammable or toxic gases |

| Automated Shutdowns and Interlocks | Prevents operation under unsafe conditions and triggers shutdowns | Reduces risk of accidents and operator error |

| High-Integrity Furnace Tubes | Made from durable materials like quartz or alumina | Maintains system integrity at high temperatures |

| Seal and Flow Path Integrity | Uses chillers and regulators to prevent leaks and over-pressurization | Protects against gas hazards and system failures |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today for expert guidance and tailored solutions that protect your operations and enhance performance!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents