The primary advantage of using a three-zone tube furnace for Fe3GeTe2 thermal treatment is the ability to independently control temperatures across distinct heating sections. Unlike a single-zone furnace, which is designed for uniform heating, a three-zone system allows you to establish a precise and stable temperature gradient between the source and growth zones.

Core Insight: The structural quality of Fe3GeTe2 crystals relies heavily on the Chemical Vapor Transport (CVT) process. A three-zone furnace is essential because it generates the specific thermal gradient required to control gaseous precursor supersaturation, which directly dictates the nucleation rate and final crystal purity.

The Role of Gradient Control in Crystal Growth

Establishing Distinct Thermal Environments

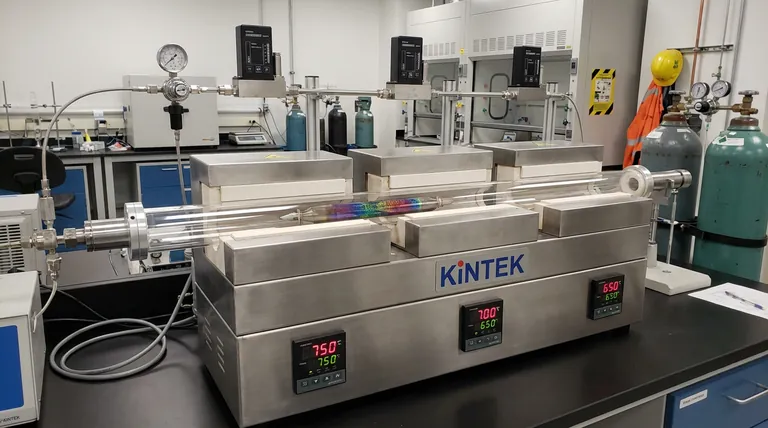

A single-zone furnace typically maintains one uniform temperature throughout the tube. In contrast, a three-zone furnace allows you to set different temperatures for the left, center, and right zones.

The Source vs. Growth Configuration

For Fe3GeTe2, this capability allows you to create a specific thermal profile essential for transport. You can maintain a high-temperature "source zone" (e.g., 750 °C) while simultaneously maintaining a lower-temperature "growth zone" (e.g., 650 °C).

Stability Across the Tube

The three-zone configuration ensures that these temperature differences are stable over time. This stability prevents fluctuations that could disrupt the delicate transport of materials from the hot end to the cool end.

Impact on the Chemical Vapor Transport (CVT) Process

Driving the Transport Mechanism

The temperature gradient is the "engine" of the CVT process. By precisely controlling the difference between the 750 °C source and the 650 °C growth zone, you create the thermodynamic drive necessary to move the material through the tube.

Controlling Supersaturation

The specific gradient determines the supersaturation of the gaseous precursor in the growth zone. If the gradient is too shallow or too steep, the saturation levels will not support optimal growth.

Regulating Nucleation and Quality

Supersaturation directly influences the nucleation rate. By fine-tuning the zones to manage this rate, you ensure the Fe3GeTe2 crystals grow with high structural quality rather than forming amorphous or defect-heavy solids.

Broader Operational Benefits

Mitigation of Edge Effects

Even if you aim for a relatively flat profile, single-zone furnaces often suffer from heat loss at the ends of the tube. A three-zone furnace can compensate for this by applying slightly higher power to the outer zones, ensuring true uniformity across the central length.

Process Flexibility

The ability to customize profiles provides significant versatility. You can run complex, multi-stage temperature programs that a single-zone controller cannot replicate, adapting to different material requirements beyond Fe3GeTe2.

Understanding the Trade-offs

Complexity of Calibration

With three independent controllers, the system is inherently more complex. Achieving a linear or specific non-linear gradient requires careful calibration to ensure one zone's heat does not inadvertently destabilize the adjacent zone.

Application Mismatch

If your goal is purely isothermal treatment—such as long-term annealing where the entire sample must stay at exactly 700 °C to eliminate segregation—a three-zone furnace may be unnecessary. In such cases, the simplicity of a single-zone furnace is often sufficient and more cost-effective.

Making the Right Choice for Your Goal

To maximize the quality of your Fe3GeTe2 crystals, align your equipment choice with your specific process step:

- If your primary focus is Chemical Vapor Transport (CVT): You must use a three-zone furnace to establish the precise 750 °C to 650 °C gradient required for controlled nucleation.

- If your primary focus is simple solid-phase annealing: A single-zone furnace may suffice, provided it offers a stable isothermal field for long-duration treatments.

- If your primary focus is process reproducibility: The three-zone system offers superior control over thermal profiles, reducing material waste and ensuring consistent output batches.

By leveraging the independent control of a three-zone system, you move from simple heating to precise thermodynamic engineering of your crystal growth environment.

Summary Table:

| Feature | Single-Zone Tube Furnace | Three-Zone Tube Furnace |

|---|---|---|

| Temperature Profile | Uniform / Isothermal | Customizable Gradient |

| Control Mechanism | Single Controller | Three Independent Controllers |

| CVT Suitability | Low (Difficult to maintain gradient) | High (Ideal for source/growth zones) |

| Edge Effect Mitigation | Poor (Heat loss at ends) | Excellent (Compensated by outer zones) |

| Best Use Case | Basic Annealing & Sintering | Complex Crystal Growth & CVD/CVT |

Elevate Your Crystal Growth Precision with KINTEK

Unlock the full potential of your Fe3GeTe2 synthesis and Chemical Vapor Transport (CVT) processes. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you need advanced Three-Zone Tube Furnaces, CVD systems, or custom high-temperature lab furnaces, our equipment is designed to deliver the exact thermal gradients required for high-purity results.

Ready to optimize your lab’s efficiency and reproducibility?

Contact KINTEK today to discuss your customizable furnace needs

References

- Microthermoreflectance Characterization of the Band‐Structure Transformations Observed During the Magnetic‐Ordering Transitions of Multilayered 2D Fe <sub>3</sub> GeTe <sub>2</sub> Ferromagnetic Metals. DOI: 10.1002/smsc.202500293

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is it necessary to perform annealing in a tube furnace with a nitrogen atmosphere for VO2@AlF3 core-shell powder?

- What are the two primary types of tube furnaces and their main features? Compare Split vs. Solid Designs

- What additional features might a split tube furnace have? Boost Your Lab's Precision and Control

- How does a Tube CVD furnace facilitate the in-situ synthesis of CNT/Cu composite powders? Achieve Superior Material Bonds

- What are the advantages of resistance heating tube furnaces? Achieve Precise, Cost-Effective Thermal Processing

- How does a high-temperature tube furnace contribute to the performance of carbon nanowire networks? Enhance Electrode Performance

- What are the structural design features of an atmosphere tube furnace? Optimize Your Thermal Processing with Precision

- What functions does a high-temperature quartz tube furnace perform? Precise Synthesis of Doped Carbon Supports