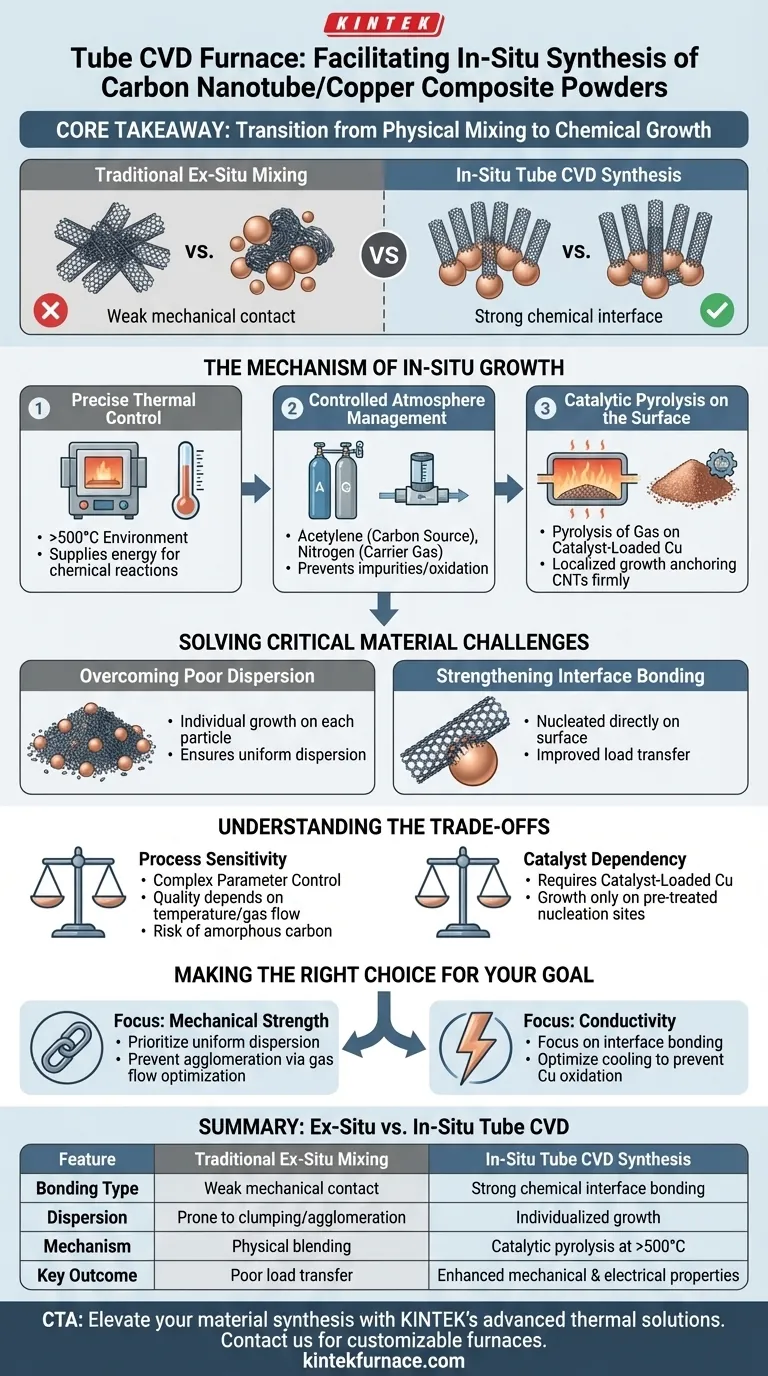

The Tube CVD furnace facilitates in-situ synthesis by creating a precisely controlled thermal and chemical environment that grows carbon nanotubes (CNTs) directly onto copper particles. Specifically, it maintains temperatures typically above 500°C while introducing a carbon-rich gas mixture, such as acetylene and nitrogen. This setup triggers the pyrolysis of the gas on catalyst-loaded copper, resulting in nanotubes that are chemically bonded to the metal substrate rather than just mechanically mixed.

Core Takeaway The primary advantage of using a Tube CVD furnace is the transition from physical mixing to chemical growth. By growing CNTs directly on the copper surface (in-situ), this process eliminates the agglomeration and weak interface bonding issues inherent in traditional ex-situ mixing methods.

The Mechanism of In-Situ Growth

Precise Thermal Control

The fundamental role of the Tube CVD furnace is to provide a high-temperature environment, typically exceeding 500°C.

This heat is critical for initiating the chemical reactions necessary for synthesis. It supplies the energy required to break down carbon precursor gases into atomic carbon.

Controlled Atmosphere Management

The tube design allows for the introduction of specific gas mixtures, such as acetylene (the carbon source) and nitrogen (the carrier or protective gas).

By strictly controlling this atmosphere, the furnace ensures that the carbon is available for growth without introducing unwanted impurities or uncontrolled oxidation.

Catalytic Pyrolysis on the Surface

Inside the heated zone, the carbon source gas undergoes pyrolysis (thermal decomposition).

Because the copper powder is loaded with a catalyst, this decomposition happens specifically on the surface of the copper particles. This localization ensures that the carbon nanotubes grow outwards from the copper, anchoring them firmly to the metal.

Solving Critical Material Challenges

Overcoming Poor Dispersion

Traditional methods often involve physically mixing loose CNTs with copper powder, which leads to clumping and uneven distribution.

The Tube CVD method solves this by growing the nanotubes individually on each copper particle. This ensures uniform dispersion throughout the composite powder before it is ever consolidated into a solid part.

Strengthening Interface Bonding

In ex-situ mixing, the CNTs and copper interact only through weak mechanical contact.

The in-situ growth facilitated by the furnace creates a strong interface bond. Since the CNTs are nucleated directly on the copper surface, the load transfer between the matrix (copper) and the reinforcement (CNT) is significantly improved.

Understanding the Trade-offs

Process Sensitivity

While the Tube CVD furnace creates superior materials, it introduces complexity regarding parameter control.

The quality of the CNTs depends heavily on maintaining exact temperatures and gas flow rates. Deviations can lead to incomplete growth or the formation of amorphous carbon rather than structured nanotubes.

Catalyst Dependency

The process described relies on catalyst-loaded copper powder.

The furnace facilitates the growth, but the copper powder must be pre-treated with a catalyst to serve as effective nucleation sites. The furnace cannot force growth on inert, untreated copper surfaces without this catalytic driver.

Making the Right Choice for Your Goal

To maximize the effectiveness of a Tube CVD furnace for this application, consider your specific end-goals:

- If your primary focus is mechanical strength: Prioritize the uniform dispersion aspect; ensure your gas flow rates prevent carbon saturation that could lead to agglomeration.

- If your primary focus is conductivity: Focus on the interface bonding; optimize the cooling phase in the controlled atmosphere to prevent post-growth oxidation of the copper.

The Tube CVD furnace is not just a heater; it is a reactor that replaces the mechanical limitations of mixing with the chemical precision of growth.

Summary Table:

| Feature | Traditional Ex-Situ Mixing | In-Situ Tube CVD Synthesis |

|---|---|---|

| Bonding Type | Weak mechanical contact | Strong chemical interface bonding |

| Dispersion | Prone to clumping/agglomeration | Individualized growth on each particle |

| Mechanism | Physical blending of powders | Catalytic pyrolysis at >500°C |

| Key Outcome | Poor load transfer | Enhanced mechanical & electrical properties |

Elevate your material synthesis with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of in-situ synthesis and material research. Whether you are optimizing interface bonding or ensuring uniform dispersion for next-generation composites, our lab high-temp furnaces provide the precision you need. Contact KINTEK today to discuss your unique project requirements!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the technical advantages of using a PID programmable controller in tube furnace control modules?

- Why is a high-temperature tube furnace necessary for carbonization of biochar? Unlock High-Performance Electrodes

- What is the primary role of a dual-temperature zone tube furnace in CVT? Precision Gradient Control for SnS2 Synthesis

- Why is a horizontal tube furnace utilized for BPEA growth? Mastering Physical Vapor Transport for Single Crystals

- What is the function of a laboratory high-temperature tube furnace? Driving Topotactic Reduction of Nickelate Films

- What problems existed with early tube furnace designs? Discover the Flaws That Hindered Performance

- What atmospheric control features do horizontal tube furnaces offer? Enhance Precision in Material Processing

- How do high-temperature tube furnaces facilitate growth control in MoS2 LPCVD? Precision Synthesis Techniques