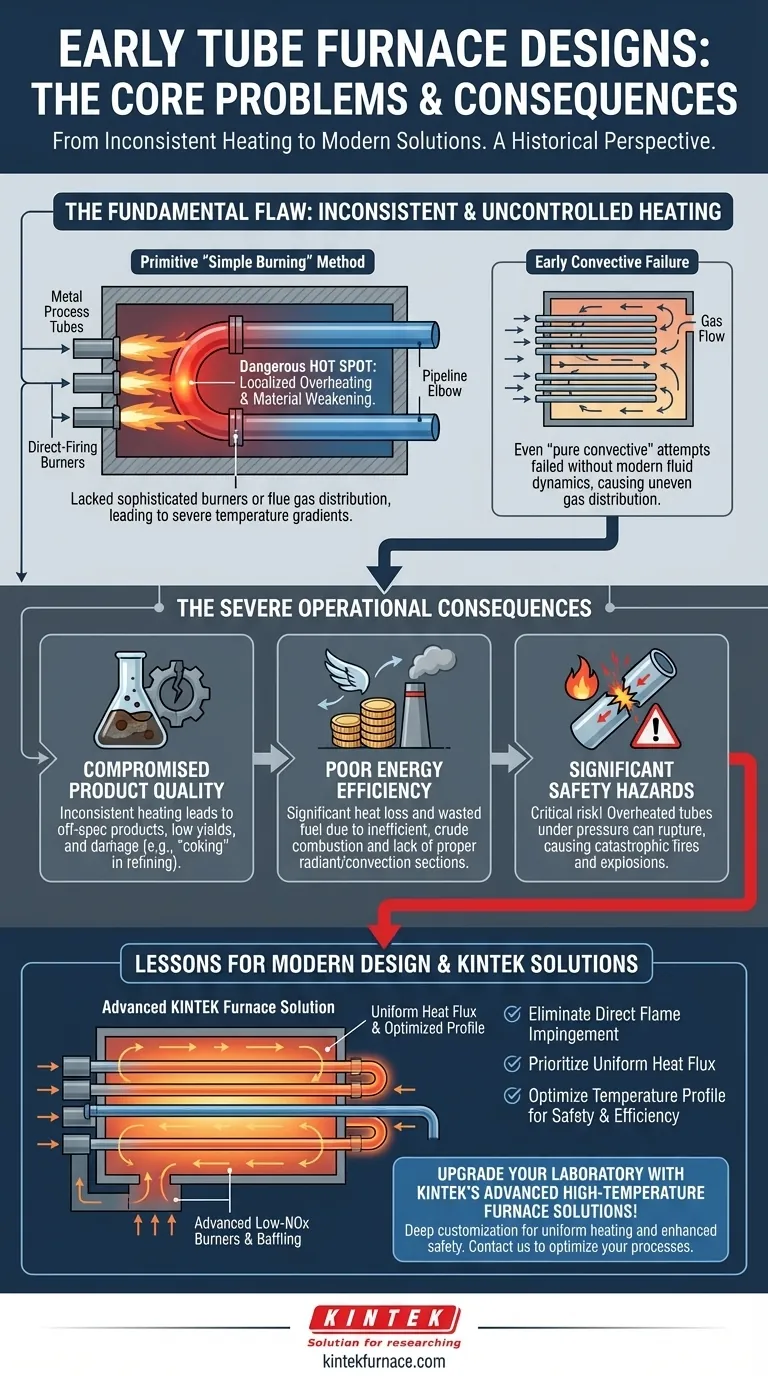

The fundamental flaw of early tube furnace designs was their inability to provide consistent, uniform heat across the process tubes. These primitive systems relied on crude, direct-firing methods where flames often impinged directly on the tubes, especially at the elbows. This created dangerous hot spots and left other areas underheated, a problem that persisted even in early attempts to create purely convective ovens.

The core issue with early furnaces was not merely inconsistent temperature, but the severe operational consequences that followed: poor energy efficiency, compromised product quality, and significant safety risks from uncontrolled, localized overheating.

The Core Problem: Inconsistent and Uncontrolled Heating

The primary goal of a process furnace is to transfer thermal energy in a predictable and uniform manner. Early designs failed at this fundamental task due to their simplistic approach to combustion and heat transfer.

The "Simple Burning" Method

Early furnaces often involved little more than directing a flame toward the tubes that needed to be heated. This method lacked any sophisticated burner technology or systems for distributing hot flue gases evenly.

The result was intense, concentrated heat in some areas and a near-complete lack of it in others. The reference to "fire at the elbow of each pipeline" highlights this crude approach, where the most vulnerable points of the tubing received the most aggressive heating.

Hot Spots and Localized Overheating

Direct flame impingement is highly destructive. It creates "hot spots" where the tube metal temperature rises far beyond the design limits.

This localized overheating dramatically weakens the material's structural integrity, especially at pipeline elbows, which are already points of high mechanical stress. This made the tubes susceptible to warping, scaling, and eventual rupture.

Failure of Early Convective Solutions

Engineers recognized the problem of direct heating and attempted to create furnaces that relied solely on convection—heating the tubes with hot gas rather than direct flames.

However, these early "pure convective ovens" also failed to deliver even heating. Without a modern understanding of fluid dynamics, they lacked the proper baffling and circulation design needed to ensure the hot gases would distribute evenly throughout the furnace box. Hot gas would still channel to certain areas, perpetuating the core problem of an inconsistent temperature profile.

Understanding the Consequences

The flaws of early furnace designs were not just theoretical. They carried severe and costly consequences that limited their effectiveness and made them hazardous to operate.

Compromised Product Quality

Uneven heating leads directly to inconsistent product. In a refining or chemical process, sections of the fluid moving through overheated tubes could be damaged or "coked" (forming hard carbon deposits), while fluid in cooler tubes would be under-processed. This resulted in low yields and off-spec products.

Poor Energy Efficiency

Directing a flame at a small target like a pipe is incredibly inefficient. A massive amount of thermal energy was simply lost as hot gas escaped the furnace without ever transferring its heat to the process fluid. The lack of a well-designed radiant or convection section meant most of the fuel was wasted.

Significant Safety Hazards

This was the most critical consequence. Overheated tubes operating under high pressure are a recipe for catastrophic failure. A tube rupture would release flammable process fluids into a fired environment, leading to fires and explosions that posed an extreme risk to personnel and the entire facility.

Lessons from Early Designs for Modern Applications

Understanding these historical failures provides a clear perspective on the principles that govern modern furnace design. The solutions to these early problems are now considered standard best practices.

- If your primary focus is process control: Recognize that uniform heat flux is the cornerstone of modern furnace design, achieved through advanced, low-NOx burners and optimized radiant/convective section layouts.

- If your primary focus is safety and reliability: Prioritize designs that eliminate any possibility of direct flame impingement on tubes, as this was the single most critical failure point of early systems.

- If your primary focus is evaluating furnace performance: Always investigate the temperature profile across all tubes. The presence of hot spots remains a classic indicator of a design or operational flaw that traces back to these foundational challenges.

By engineering sophisticated solutions for heat distribution and control, modern furnaces have overcome the fundamental problems that plagued their predecessors.

Summary Table:

| Problem | Description | Consequence |

|---|---|---|

| Inconsistent Heating | Direct flame impingement caused hot spots and uneven temperature distribution. | Compromised product quality and low yields. |

| Poor Energy Efficiency | Crude combustion methods led to significant heat loss and wasted fuel. | High operational costs and inefficiency. |

| Safety Hazards | Localized overheating weakened tubes, risking rupture, fires, and explosions. | Severe risks to personnel and facilities. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering uniform heating, enhanced safety, and superior efficiency. Contact us today to discuss how we can optimize your processes and overcome historical design flaws!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability