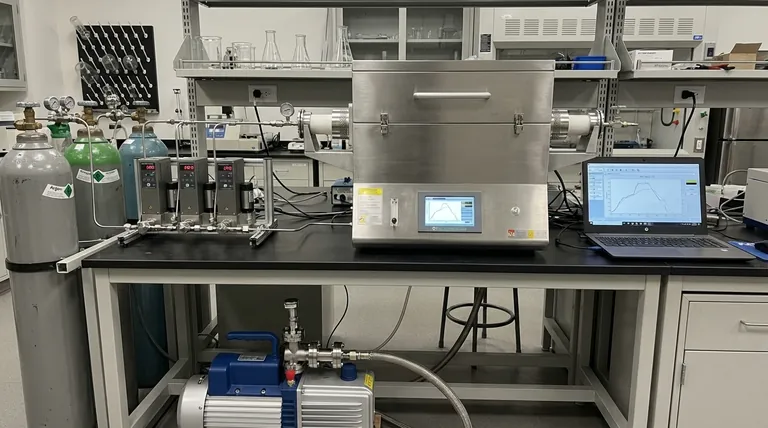

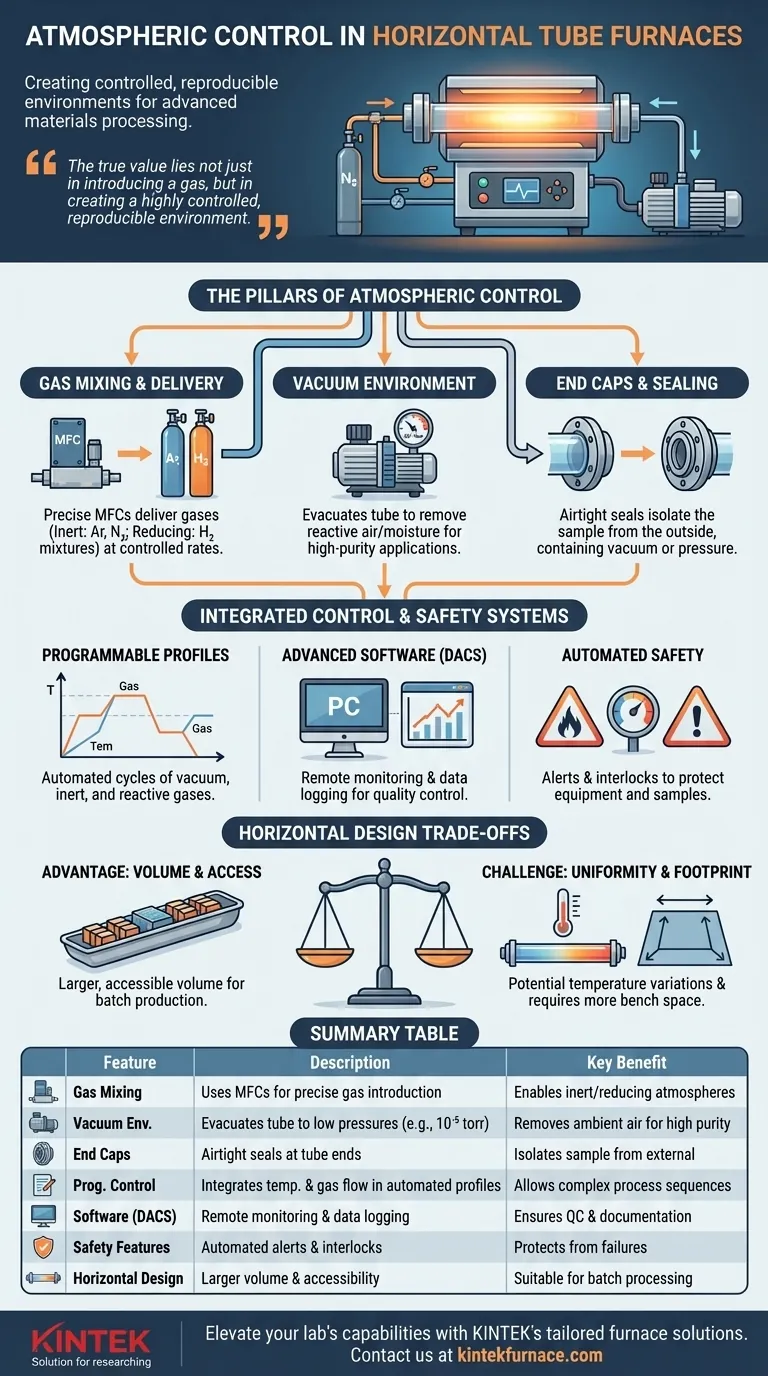

At their core, horizontal tube furnaces offer sophisticated atmospheric control by enabling you to precisely manage the gas environment or vacuum level inside the sealed heating tube. This is primarily achieved through optional gas mixing and delivery systems, vacuum pump integration, and sealed end caps. These features allow you to heat materials under specific conditions, such as an inert atmosphere like argon to prevent oxidation, or a reducing atmosphere to drive specific chemical reactions.

The true value of a horizontal tube furnace's atmospheric control lies not just in introducing a gas, but in its ability to create and maintain a highly controlled, reproducible environment. This integration of gas, vacuum, and temperature management is what prevents unwanted reactions and enables advanced materials processing.

The Pillars of Atmospheric Control

True control over your process atmosphere is built on a few key hardware and system capabilities working in concert.

Gas Mixing and Delivery Systems

The most fundamental feature is a gas management system. These systems use mass flow controllers (MFCs) to deliver one or more gases into the process tube at precisely controlled rates.

This allows you to create specific environments, such as a pure inert atmosphere (e.g., Argon, Nitrogen) to protect sensitive materials from oxygen, or a reducing atmosphere (e.g., Hydrogen mixtures) to actively remove oxides.

Creating a Vacuum Environment

Before introducing a process gas, it's often critical to remove the ambient air, which is rich in reactive oxygen and moisture. High-end tube furnaces can be equipped with vacuum-tight flanges and ports.

By connecting a vacuum pump, you can evacuate the tube to pressures as low as 10⁻⁵ torr. This initial purge is essential for high-purity applications, ensuring the process starts in an exceptionally clean environment before the desired gas is introduced.

The Role of End Caps and Sealing

None of this would be possible without the ability to physically seal the process tube. Specialized end caps or flanges are used to create an airtight seal at both ends of the tube.

These components are what contain the vacuum or the positive pressure of the process gas, isolating the sample from the outside environment. They also house the ports for gas inlet/outlet and instrumentation.

Integrated Control and Safety Systems

Modern furnaces integrate atmospheric controls directly into the central operating system, moving beyond simple manual adjustments.

Programmable Temperature and Gas Profiles

The furnace's control panel or associated software allows you to program not just the temperature ramp and dwell times, but also the gas flow. You can program the system to automatically switch between vacuum, inert gas, and reactive gas at different stages of the heating cycle.

Advanced Software Integration (DACS)

For maximum control and repeatability, systems often include Data Acquisition and Control Software (DACS). This allows you to program, monitor, and control the entire process remotely from a PC.

Crucially, this software logs all parameters—temperature, gas flow rates, pressure—creating a complete record of the process for quality control and research purposes.

Automated Safety Features

Integrated systems include programmable alerts and interlocks for safety. For example, the system can be configured to shut down the heating elements if gas flow unexpectedly stops or if a pressure limit is exceeded, protecting both the equipment and the sample.

Understanding the Trade-offs of a Horizontal Design

While powerful, the horizontal orientation comes with specific considerations that may influence your application.

Advantage: Sample Volume and Access

Horizontal furnaces generally offer a larger and more accessible working volume. This makes them well-suited for processing larger individual samples or multiple smaller samples arranged in a boat for batch production.

Challenge: Temperature Uniformity

While designed for excellent heat distribution, the horizontal orientation can sometimes introduce slight temperature variations along the length of the tube due to natural convection. Achieving perfect uniformity may require careful sample placement and optimization of the temperature profile, especially in longer furnaces.

Challenge: Physical Footprint and Handling

By their nature, horizontal furnaces have a larger physical footprint and require more bench space than their vertical counterparts. Placing and retrieving samples, especially delicate powders in a long tube, can also be more challenging compared to a vertical furnace where gravity assists with loading.

Choosing the Right Features for Your Application

The ideal configuration depends entirely on your experimental or production goals.

- If your primary focus is high-purity material annealing: Prioritize a system with high-vacuum capability (10⁻⁵ torr) to thoroughly purge oxygen before backfilling with a high-purity inert gas.

- If your primary focus is chemical vapor deposition (CVD) or reduction: A multi-gas system with precise mass flow controllers is essential for managing precursor and carrier gas mixtures.

- If your primary focus is process repeatability for quality control: Integrated control software (DACS) is non-negotiable for programming complex profiles and logging all process data.

- If your primary focus is processing larger batches of samples: The horizontal design is ideal, but be prepared to validate the temperature uniformity across your sample boat to ensure consistent results.

By understanding these integrated features, you can configure a furnace that serves not just as a heater, but as a precise and repeatable processing environment.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Gas Mixing and Delivery | Uses mass flow controllers for precise gas introduction | Enables inert or reducing atmospheres to prevent oxidation or drive reactions |

| Vacuum Environment | Evacuates tube to low pressures (e.g., 10⁻⁵ torr) | Removes ambient air for high-purity applications |

| End Caps and Sealing | Airtight seals at tube ends | Isolates sample from external environment |

| Programmable Control | Integrates temperature and gas flow in automated profiles | Allows complex process sequences and repeatability |

| Software Integration (DACS) | Remote monitoring and data logging | Ensures quality control and process documentation |

| Safety Features | Automated alerts and interlocks | Protects equipment and samples from failures |

| Horizontal Design | Larger working volume and sample accessibility | Suitable for batch processing and larger samples |

Ready to elevate your laboratory's capabilities with advanced atmospheric control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Whether you're focused on high-purity annealing, CVD processes, or batch production, our expertise ensures precise, repeatable results. Contact us today to discuss how we can optimize your material processing environment!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing