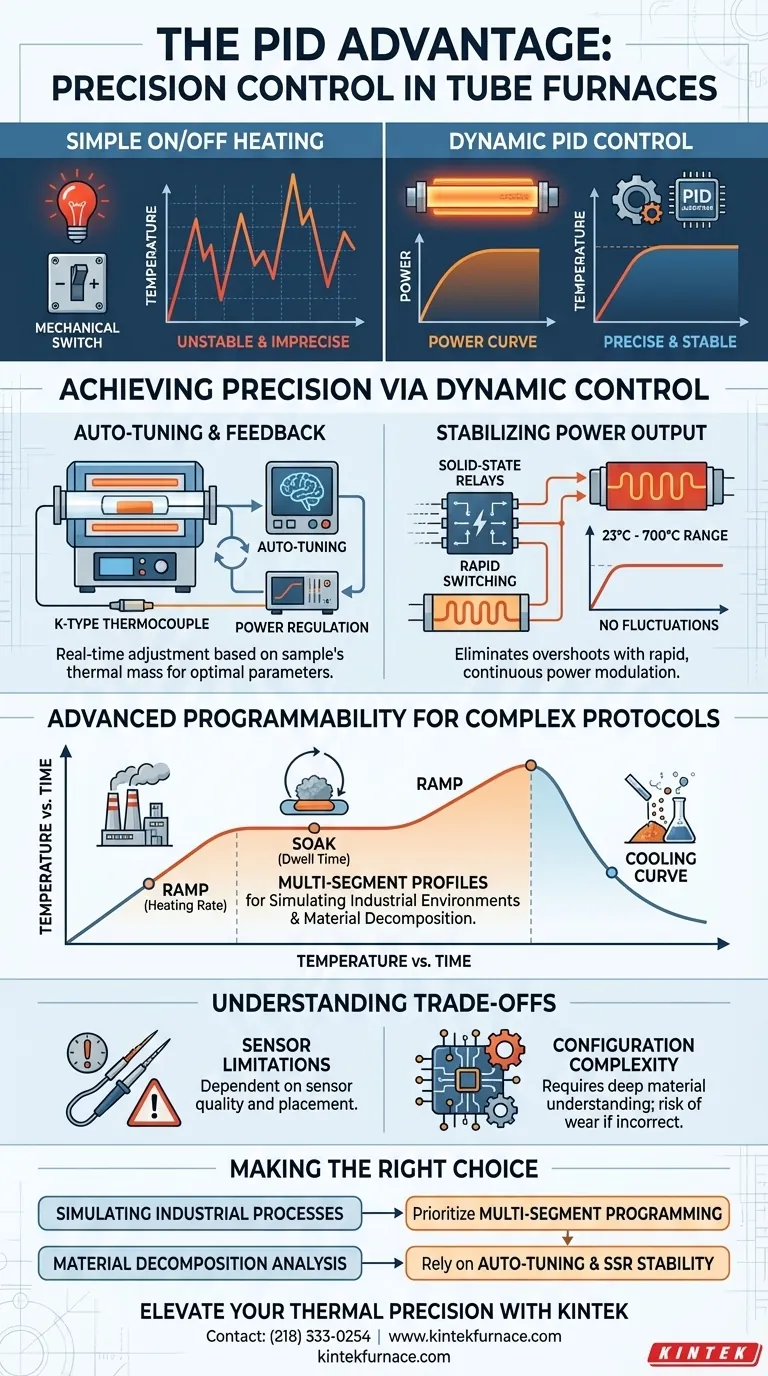

A PID programmable controller delivers precise thermal management by utilizing auto-tuning algorithms to regulate the power output of heating elements, such as iron-chromium-aluminum alloy wires. It enables complex, multi-segment temperature profiles—defining specific heating rates, dwell times, and cooling curves—which are critical for simulating industrial combustion environments and ensuring accurate thermal decomposition studies.

Core Takeaway The true value of a PID controller in a tube furnace is the transition from simple on/off heating to dynamic, feedback-driven regulation. By continuously adjusting power output to eliminate fluctuations, it guarantees the precise thermodynamic conditions necessary for reproducible pyrolysis and material analysis.

Achieving Precision via Dynamic Control

The Role of Auto-Tuning and Feedback

The foundation of this technology is the auto-tuning function. This feature automatically calculates the optimal control parameters required to regulate the power output of the heating elements.

By monitoring real-time feedback from a K-type thermocouple located inside the heater, the controller adjusts the system to match the specific thermal mass of your sample.

Stabilizing Power Output

Unlike basic thermostats that cycle power fully on or off, a PID algorithm uses solid-state relays to modulate power dynamically.

This rapid adjustment eliminates the temperature overshoots and fluctuations common in simpler systems. It ensures stable setpoints across a wide range, typically from 23°C to 700°C, maintaining the integrity of the thermal environment.

Advanced Programmability for Complex Protocols

Multi-Segment Temperature Profiles

For advanced research, maintaining a single temperature is often insufficient. PID controllers in these modules support multi-segment programs.

You can program specific heating rates (ramp), precise dwell times (soak), and controlled cooling curves. This capability allows you to replicate exact thermal histories rather than just reaching a peak temperature.

Simulating Industrial Environments

This programmability is essential for simulating industrial combustion environments.

By controlling the exact rate of temperature change, researchers can study the thermal decomposition characteristics of materials under realistic conditions. This is particularly vital for experiments involving the pyrolysis of materials in specific combustion modes.

Understanding the Trade-offs

Sensor Limitations and Thermal Lag

While PID algorithms are highly accurate, they are dependent on the quality of their input data. The system relies on a K-type thermocouple; if this sensor is poorly positioned or degraded, the controller’s precision is compromised regardless of the algorithm's quality.

Complexity of Configuration

The flexibility of multi-segment programming introduces complexity. Designing an effective thermal profile requires a deep understanding of the material's properties. Incorrectly setting ramp rates that exceed the physical capabilities of the iron-chromium-aluminum alloy wires can lead to system wear or inaccurate test data.

Making the Right Choice for Your Experiment

To maximize the utility of a PID-controlled tube furnace, align the controller's features with your specific research goals:

- If your primary focus is Simulating Industrial Processes: Prioritize the multi-segment programming features to replicate exact heating rates and cooling curves found in large-scale combustion.

- If your primary focus is Material Decomposition Analysis: Rely on the auto-tuning and solid-state relay integration to ensure the stable, fluctuation-free temperatures required for precise pyrolysis data.

By leveraging these programmable features, you transform a standard heating element into a high-precision instrument capable of rigorous thermodynamic verification.

Summary Table:

| Feature | Technical Advantage | Research Benefit |

|---|---|---|

| Auto-Tuning | Automatically calculates optimal control parameters | Eliminates temperature overshoots and manual calibration |

| Multi-Segment Programming | Defines specific ramp rates, dwell times, and cooling curves | Enables simulation of complex industrial combustion environments |

| Solid-State Relays | Rapid, dynamic modulation of power output | Ensures high stability across a 23°C to 700°C range |

| Feedback Loop | Real-time monitoring via K-type thermocouples | Guarantees reproducible pyrolysis and decomposition data |

Elevate Your Thermal Precision with KINTEK

Maximize your research accuracy with advanced PID-controlled systems tailored for complex thermal profiles. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory needs. Whether you are simulating industrial environments or conducting precise material analysis, our high-temp furnaces provide the stability and control you demand.

Ready to optimize your lab's efficiency? Contact KINTEK today to discuss your custom furnace solution!

Visual Guide

References

- Beata Brzychczyk, L. J. Sikora. Modernization of a Tube Furnace as Part of Zero-Waste Practice. DOI: 10.3390/su17198940

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does the design of an electrically heated cylindrical reaction chamber influence nitriding for AISI 1085 steel?

- What role does an industrial-grade high-temperature tube furnace play in the two-step pyrolysis of Fe–Mn–N–C? Optimize Synthesis

- Why does a tube sintering furnace require precise control for (RuIr)O2/C catalysts? Optimize Catalyst Performance

- What is the core role of a tubular furnace in the direct pyrolysis of biomass into biochar? Master Carbon Engineering

- How does a vacuum tube furnace work? Master Precise High-Temp Material Processing

- How does a high-temperature quartz tube reactor facilitate the synthesis of PC-CNT microspheres? Expert Insights

- What are the benefits of quartz tube furnaces? Achieve Purity and Visibility in High-Temp Processes

- How does a laboratory horizontal tube furnace establish a controlled environment? Precision Corrosion Testing Guide