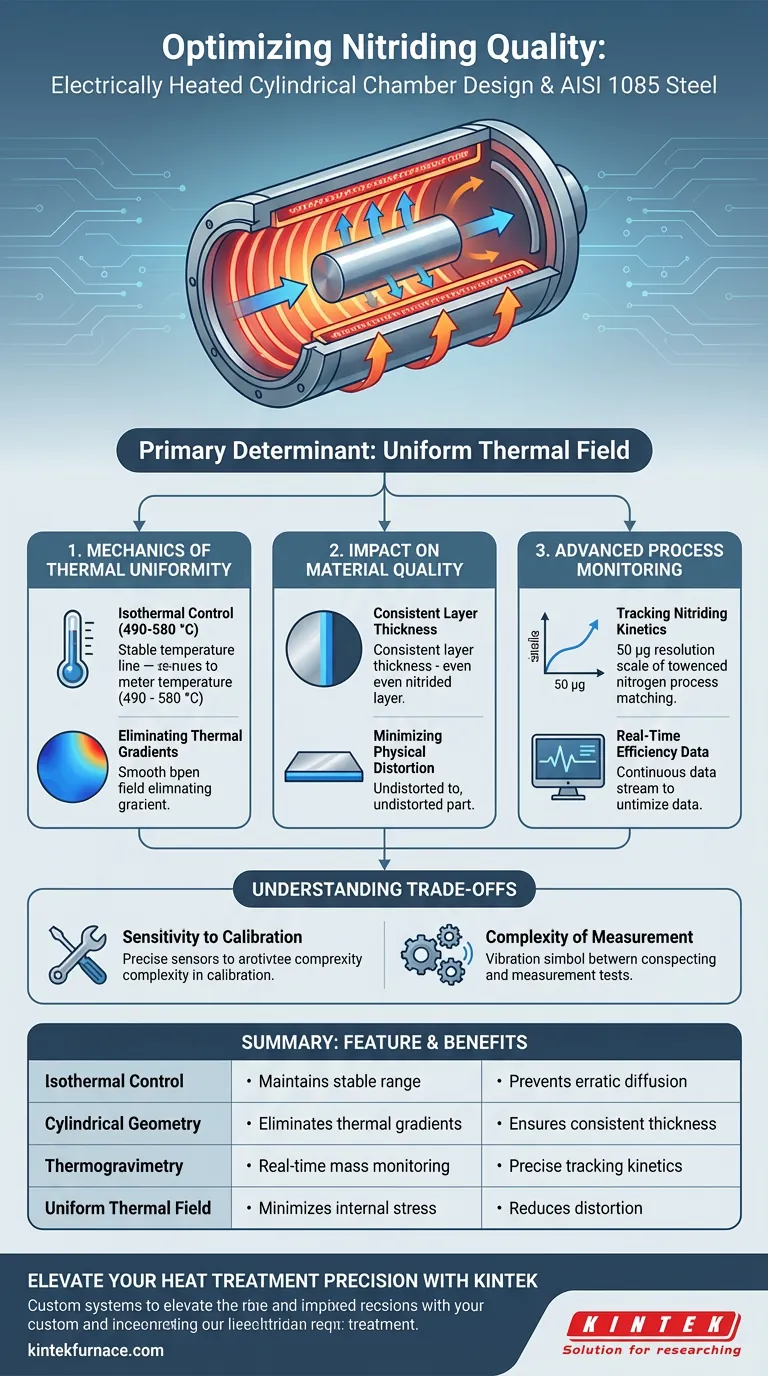

The design of an electrically heated cylindrical reaction chamber is the primary determinant of surface hardening consistency. By utilizing a precise temperature control system, the chamber creates a highly uniform thermal field that is essential for treating AISI 1085 steel. This thermal stability ensures that nitrogen diffusion occurs at a constant rate across the entire surface, preventing physical distortion and guaranteeing a uniform hardened layer.

Core Takeaway The quality of nitriding relies heavily on the chamber’s ability to maintain strict isothermal conditions between 490 and 580 °C. Without this geometric and thermal precision, nitrogen diffusion becomes erratic, leading to uneven layer thickness and structural warping.

The Mechanics of Thermal Uniformity

Establishing Isothermal Control

The fundamental role of the cylindrical chamber design is to maintain a specific temperature range, typically between 490 and 580 °C for AISI 1085 steel.

Reliable nitriding requires this environment to be isothermal. The electrical heating elements are arranged to ensure the entire reaction zone remains at the target temperature without fluctuation.

Eliminating Thermal Gradients

In a well-designed cylindrical chamber, the thermal field envelops the steel sample evenly.

This eliminates "cold spots" or "hot spots" on the steel surface. Such gradients are the primary cause of inconsistent treatment results in less sophisticated equipment.

Impact on Material Quality

Consistent Layer Thickness

The rate at which nitrogen atoms diffuse into steel is governed by temperature.

Because the chamber ensures the temperature is identical at every point on the sample, the diffusion rate becomes uniform. This results in a hardened nitriding layer that has consistent thickness across the complex geometry of the part.

Minimizing Physical Distortion

Uneven heating creates internal stresses within the steel lattice.

By prioritizing a uniform thermal field, the chamber design minimizes these stresses. This results in a finished component that retains its original dimensions with minimal distortion or warping.

Advanced Process Monitoring

Tracking Nitriding Kinetics

sophisticated reaction chambers are often integrated with high-precision thermogravimetric measurement systems.

These systems are capable of detecting mass changes with a resolution of 50 µg. This allows for the precise observation of reaction kinetics during the actual heat treatment.

Real-Time Efficiency Data

The design enables the continuous recording of mass increase as nitrogen atoms diffuse into the steel.

This provides operators with real-time data on the growth pattern of the nitriding layer and the overall reaction efficiency, all without interrupting the experimental process.

Understanding the Trade-offs

Sensitivity to Calibration

Achieving an "extremely uniform thermal field" requires rigorous sensor calibration.

If the temperature control system drifts even slightly, the isothermal conditions can be compromised. This makes regular maintenance and calibration critical for maintaining quality.

Complexity of Measurement

Integrating high-resolution mass measurement (50 µg) increases equipment complexity.

While valuable for research and precise quality control, this feature adds a layer of operational sensitivity. It requires a stable environment free from external vibrations that could skew the sensitive weight measurements.

Making the Right Choice for Your Goal

To maximize the quality of your nitriding treatment, align your equipment choice with your specific objectives:

- If your primary focus is Dimensional Stability: Prioritize a chamber with a proven isothermal thermal field to minimize distortion and ensure uniform layer thickness.

- If your primary focus is Process Research: Prioritize a reactor with high-resolution thermogravimetric capabilities to monitor diffusion kinetics and reaction efficiency in real-time.

The synergy between cylindrical geometry and precise electrical heating is the foundation of reproducible, high-quality nitriding.

Summary Table:

| Feature | Impact on Nitriding Quality | Benefit for AISI 1085 Steel |

|---|---|---|

| Isothermal Control | Maintains stable 490–580 °C range | Prevents erratic nitrogen diffusion |

| Cylindrical Geometry | Eliminates thermal gradients/hot spots | Ensures consistent hardened layer thickness |

| Thermogravimetry | Real-time mass change monitoring (50 µg) | Precise tracking of nitriding kinetics |

| Uniform Thermal Field | Minimizes internal lattice stress | Reduces physical distortion and warping |

Elevate Your Heat Treatment Precision with KINTEK

Consistency in nitriding is only as reliable as your thermal environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to meet your unique metallurgical requirements. Whether you are processing AISI 1085 steel or developing new material coatings, our lab high-temp furnaces provide the isothermal stability and real-time monitoring needed for superior results.

Ready to optimize your thermal field? Contact our experts today to discuss your custom furnace solution.

Visual Guide

References

- T. Frączek, M. Ogórek. The Influence of Selected Process Parameters on the Efficiency of the Process of Gas Nitriding of AISI 1085 Steel. DOI: 10.3390/ma17112600

This article is also based on technical information from Kintek Furnace Knowledge Base .

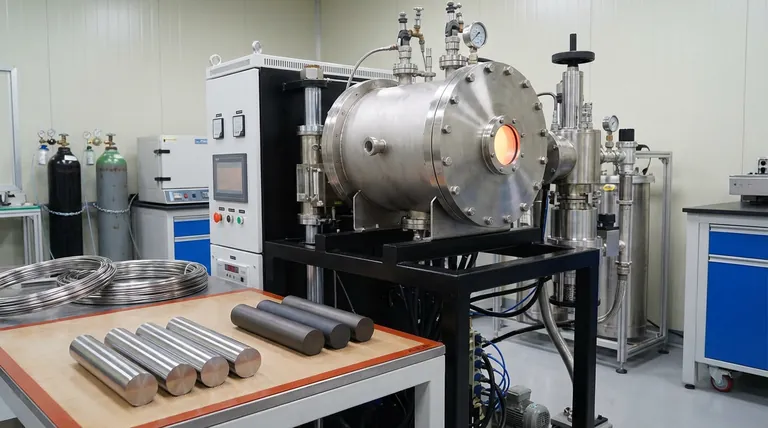

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does oxygen atmosphere treatment in a tube furnace affect titania nanotubes? Optimize Your Nanostructure Performance

- How to operate a tubular furnace? A 5-Phase Guide for Safe and Repeatable Results

- Why is it necessary to precisely control the oxygen flow rate in a tube furnace? Optimize Li-Deficient Composites

- Why is a controlled nitrogen atmosphere essential during the high-temperature processing of biomass in a tube furnace?

- What role does a tube furnace play in Se/NC composite synthesis? Mastering the Melt-Diffusion Method

- What is the recommended procedure for using a tube furnace after long periods of inactivity? Prevent Damage with Proper Bake-Out

- What are the types of Tube Furnaces based on tube shape? Choose Between Solid and Split for Your Lab

- Why are correct operating procedures important for laboratory tube furnaces? Ensure Safety and Accuracy in Your Experiments