In the context of furnace construction, tube furnaces are primarily classified into two types based on their physical configuration: solid tube furnaces and split tube furnaces. While both serve the same fundamental purpose of high-temperature thermal processing, their mechanical design dictates their suitability for different laboratory and industrial workflows.

The choice between a solid and split tube furnace is a trade-off between operational simplicity and experimental flexibility. Solid tube furnaces offer a robust, enclosed setup, while split tube furnaces provide superior access for complex or in-situ experiments.

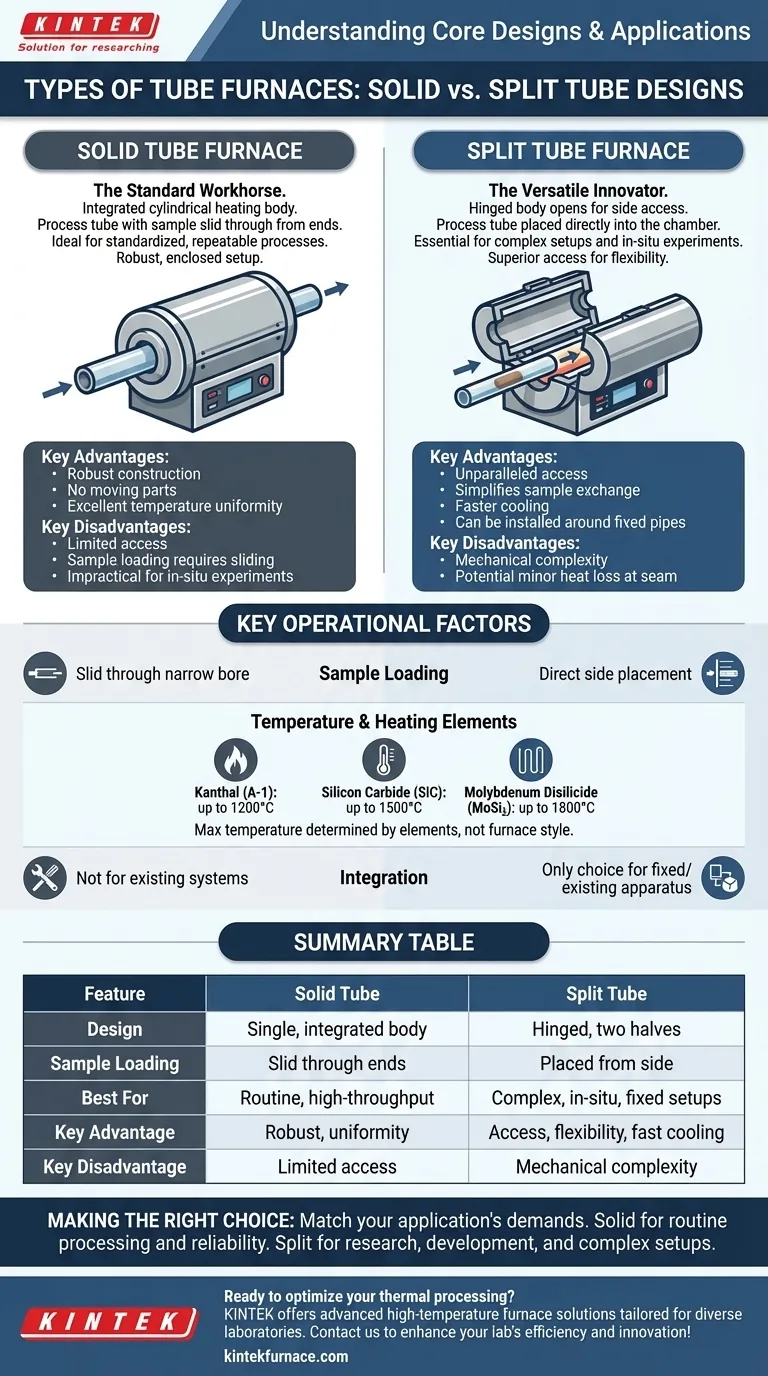

Understanding the Core Designs

The "shape" refers to the construction of the furnace body that surrounds the process tube, not the tube itself. This distinction is the most critical factor in day-to-day usability.

Solid Tube Furnaces: The Standard Workhorse

A solid tube furnace, sometimes called a non-splitting furnace, consists of a single, integrated cylindrical heating body.

The process tube, containing the sample, must be inserted or removed by sliding it through the furnace from one of the ends.

This design is prized for its structural simplicity and robustness, making it ideal for standardized, repeatable processes where the sample is easily loaded.

Split Tube Furnaces: The Versatile Innovator

A split tube furnace features a hinged body that allows it to be opened into two halves along its length.

This design allows the process tube and sample to be placed directly into the heating chamber from the side, rather than being slid in from an end.

This provides unparalleled access, which is essential for experiments that involve complex sample holders, multiple sensors, or in-situ observation. It also enables faster cooling, as the furnace can be opened to dissipate heat.

Key Operational Factors to Consider

While both furnace types can achieve the same temperature profiles, your choice directly impacts your workflow.

Sample Loading and Setup Complexity

With a solid tube furnace, the entire experimental setup inside the tube must be narrow enough to slide through the bore.

Split tube furnaces eliminate this constraint. They are essential when working with delicate samples or pre-assembled reactor configurations that cannot be disturbed by sliding them into a narrow opening.

Temperature and Heating Elements

The maximum operating temperature is determined by the heating elements, not the furnace style. Both solid and split tube models use the same technologies.

- Kanthal (A-1) elements are used for temperatures up to 1200°C.

- Silicon Carbide (SiC) elements are used for temperatures up to 1500°C.

- Molybdenum Disilicide (MoSi2) elements are required for the highest temperatures, up to 1800°C.

The choice of element is dictated by your process requirements, independent of choosing a solid or split design.

Integration with Existing Apparatus

The split tube design has a unique advantage: it can be installed around a fixed or existing pipe or reactor column.

This makes it the only choice for applications where you need to apply heat to a part of a larger, immovable system.

Understanding the Trade-offs

Neither design is universally superior. The right choice is the one that best matches your application's demands.

The Simplicity of Solid Tube Furnaces

The main advantage of a solid tube furnace is its robust construction with no moving parts in the heating chamber. This can contribute to excellent temperature uniformity.

Its primary disadvantage is the lack of access. Any adjustment or inspection of the sample during a thermal cycle requires pulling the process tube out, which is often impractical.

The Flexibility of Split Tube Furnaces

The key advantage is accessibility. This simplifies sample exchange and enables complex experimental setups that would be impossible with a solid tube design.

The main trade-off is mechanical complexity. The seam between the two halves can be a potential source of minor heat loss, though this is minimized in quality designs. The hinged mechanism is an additional component that requires proper handling.

Making the Right Choice for Your Application

Your choice depends entirely on the nature of your thermal processing tasks and experimental goals.

- If your primary focus is routine processing and reliability: A solid tube furnace is often the most straightforward and cost-effective solution for simple, high-throughput applications.

- If your primary focus is research, development, or complex setups: The superior access and flexibility of a split tube furnace are indispensable for innovation.

- If you need to place a furnace around an existing, fixed tube or column: A split tube furnace is your only viable option.

Understanding this fundamental design difference empowers you to select a tool that accelerates your work rather than complicates it.

Summary Table:

| Feature | Solid Tube Furnace | Split Tube Furnace |

|---|---|---|

| Design | Single, integrated cylindrical body | Hinged body that opens into two halves |

| Sample Loading | Slid through ends | Placed directly from the side |

| Best For | Routine, high-throughput processes | Complex setups, in-situ experiments, fixed apparatus |

| Key Advantage | Robust, simple, excellent uniformity | Superior access, flexibility, faster cooling |

| Key Disadvantage | Limited access, requires sliding setup | Potential heat loss, mechanical complexity |

Ready to optimize your thermal processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need a solid tube furnace for reliability or a split tube for flexibility, we have the expertise to help. Contact us today to discuss how our solutions can enhance your lab's efficiency and innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide