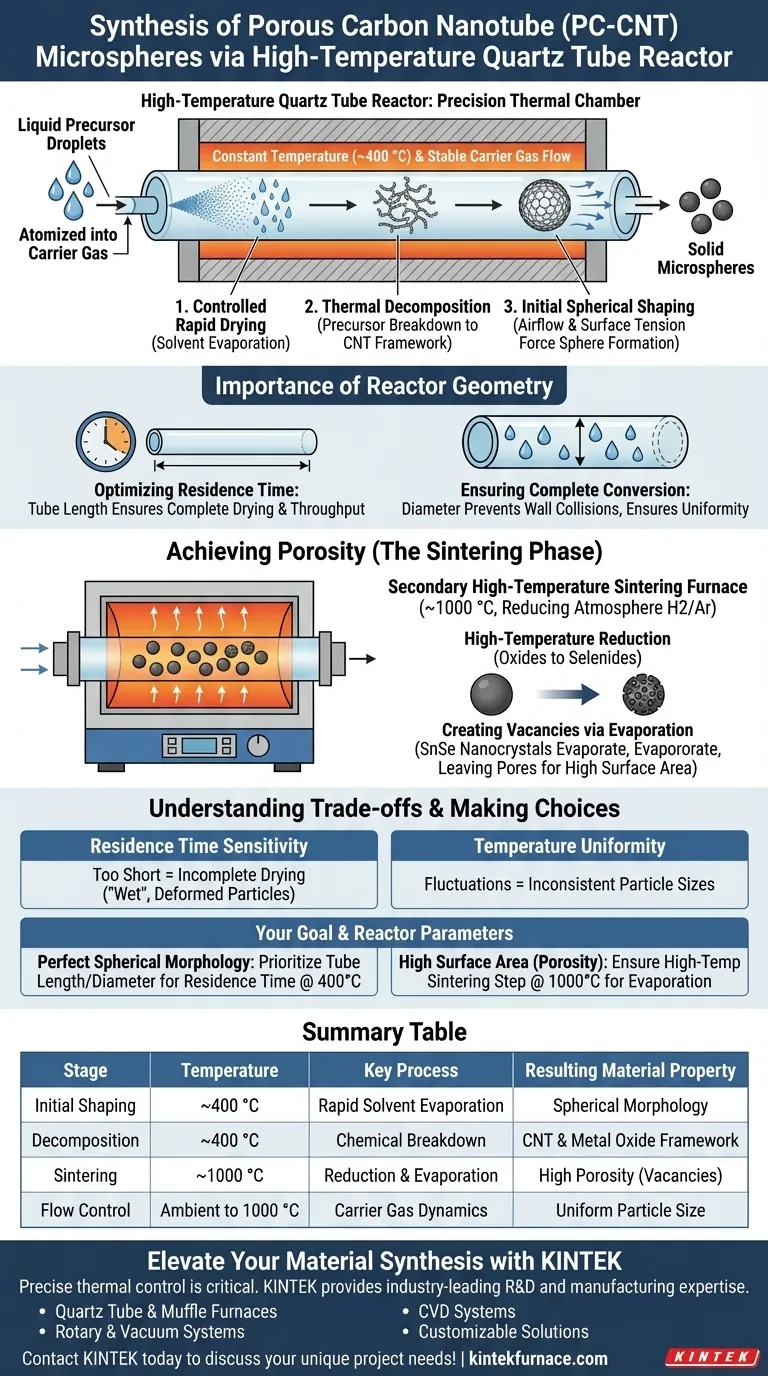

A high-temperature quartz tube reactor acts as a precision thermal chamber to transform liquid precursor droplets into solid, structured microspheres. By maintaining a constant temperature (typically around 400 °C) and a stable carrier gas flow, the reactor drives rapid drying, thermal decomposition, and the initial spherical shaping of the material.

The reactor’s optimized geometry ensures precursor droplets maintain sufficient residence time within the heating zone to fully dry and convert into spheres, setting the foundation for the subsequent creation of a high-surface-area porous structure.

The Role of Thermal Environment and Flow

The fundamental function of the quartz tube reactor is to provide a stable environment where physical and chemical transformations occur simultaneously.

Controlled Rapid Drying

The reactor maintains a constant temperature, such as 400 °C. This heat forces the solvent within the atomized spray droplets to evaporate rapidly.

Thermal Decomposition

As the solvent evaporates, the precursor materials undergo thermal decomposition. This breaks down the initial chemical compounds to leave behind the carbon nanotube framework and metal oxide precursors.

Initial Spherical Shaping

The combination of airflow and surface tension during the drying phase forces the droplets to contract. This facilitates the formation of a distinct spherical morphology, which is essential for the material's final application.

Importance of Reactor Geometry

The physical dimensions of the quartz tube are not arbitrary; they are critical engineering variables that dictate the quality of the synthesis.

Optimizing Residence Time

The length of the quartz tube determines how long the droplets remain in the heating zone. An optimized length ensures the "residence time" is long enough for complete drying but short enough to maintain throughput.

Ensuring Complete Conversion

The reactor's diameter influences the flow dynamics of the carrier gas. Correct sizing prevents wall collisions and ensures that every droplet undergoes complete component conversion before exiting the reactor.

Achieving Porosity (The Sintering Phase)

While the initial reactor stage forms the spheres, the "porous" characteristic of PC-CNT microspheres often requires a secondary high-temperature phase, typically performed in a tube sintering furnace.

High-Temperature Reduction

This stage operates at significantly higher temperatures (approx. 1000 °C) under a reducing atmosphere (e.g., H2/Ar). This environment converts oxides within the precursors into selenides.

Creating Vacancies via Evaporation

High heat triggers the complete evaporation of specific nanocrystals, such as SnSe. When these crystals evaporate, they leave behind significant vacancies, effectively creating the pores that define the high specific surface area of the final product.

Understanding the Trade-offs

Achieving uniform microspheres requires balancing several competing factors within the reactor.

Residence Time Sensitivity

If the reactor tube is too short or the gas flow too fast, the residence time decreases. This leads to incomplete drying and "wet" particles that deform rather than remaining spherical.

Temperature Uniformity

Fluctuations in the heating zone can lead to inconsistent particle sizes. Precise thermal control is required to ensure that decomposition happens uniformly across the entire batch of droplets.

Making the Right Choice for Your Goal

To maximize the efficiency of your PC-CNT synthesis, align your reactor parameters with your specific structural requirements.

- If your primary focus is Perfect Spherical Morphology: Prioritize the optimization of the tube length and diameter to ensure adequate residence time at 400 °C for shaping.

- If your primary focus is High Surface Area (Porosity): Ensure your process includes a high-temperature sintering step (1000 °C) capable of fully evaporating sacrificial nanocrystals.

The quartz tube reactor is not just a heating vessel; it is a shaping tool that uses time and temperature to sculpt liquid droplets into functional microspheres.

Summary Table:

| Stage | Temperature | Key Process | Resulting Material Property |

|---|---|---|---|

| Initial Shaping | ~400 °C | Rapid Solvent Evaporation | Spherical Morphology |

| Decomposition | ~400 °C | Chemical Breakdown | CNT & Metal Oxide Framework |

| Sintering | ~1000 °C | Reduction & Evaporation | High Porosity (Vacancies) |

| Flow Control | Ambient to 1000 °C | Carrier Gas Dynamics | Uniform Particle Size |

Elevate Your Material Synthesis with KINTEK

Precise control over thermal environments and residence time is critical for producing high-quality PC-CNT microspheres. KINTEK provides industry-leading R&D and manufacturing expertise to deliver the exact heating solutions your lab requires.

Our extensive range of high-performance lab equipment includes:

- Quartz Tube & Muffle Furnaces for precise thermal decomposition.

- Rotary & Vacuum Systems to ensure uniform heat distribution.

- CVD Systems for advanced carbon nanotube growth.

- Customizable Solutions tailored to your specific temperature and atmosphere requirements.

Whether you are focusing on spherical morphology or maximizing surface area, our expert-engineered systems provide the stability and precision you need. Contact KINTEK today to discuss your unique project needs!

Visual Guide

References

- Hyo Yeong Seo, Gi Dae Park. Engineering Porous Carbon Nanotube Microspheres with Nickel Sulfoselenide Nanocrystals for High‐Performance Potassium‐Ion Batteries: Electrochemical Mechanisms and Cycling Stability. DOI: 10.1002/sstr.202500222

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What challenges does the 70mm tube furnace market face? Overcome Technical, Quality, and Safety Hurdles

- What is the function of a high-temperature tube furnace in the preparation of Black-TiO2? Enhance Photocatalytic Power

- What thermal processes can tube furnaces be used for? Unlock Precision in Material Processing

- How is a tubular furnace utilized in the homogenization annealing of Ti-20Zr alloys? Precision Thermal Profiles

- How does a three-tube diffusion furnace ensure the quality of thermal oxidation layers? Achieve High-Efficiency Passivation

- What are the benefits of using multiple diameter tube options in a vertical tube furnace? Boost Lab Versatility and Efficiency

- How is the temperature controlled in a tube furnace? Achieve Precise Thermal Processing for Your Lab

- How does tube furnace cracking compare to fuel furnaces in terms of efficiency? Discover Higher Efficiency and Precision