Tube furnaces are versatile instruments capable of executing a wide range of high-temperature thermal processes. Their core applications include the purification of organic and inorganic compounds, annealing materials to alter their properties, drying, coating, sintering powdered materials, and performing controlled chemical synthesis. The key to their utility lies in providing a highly uniform and atmospherically controlled heating environment.

A tube furnace's primary advantage is not just its ability to generate heat, but its power to create a precisely controlled and isolated thermal environment. This control over temperature and atmosphere is what enables its use across a diverse spectrum of sensitive material processing applications.

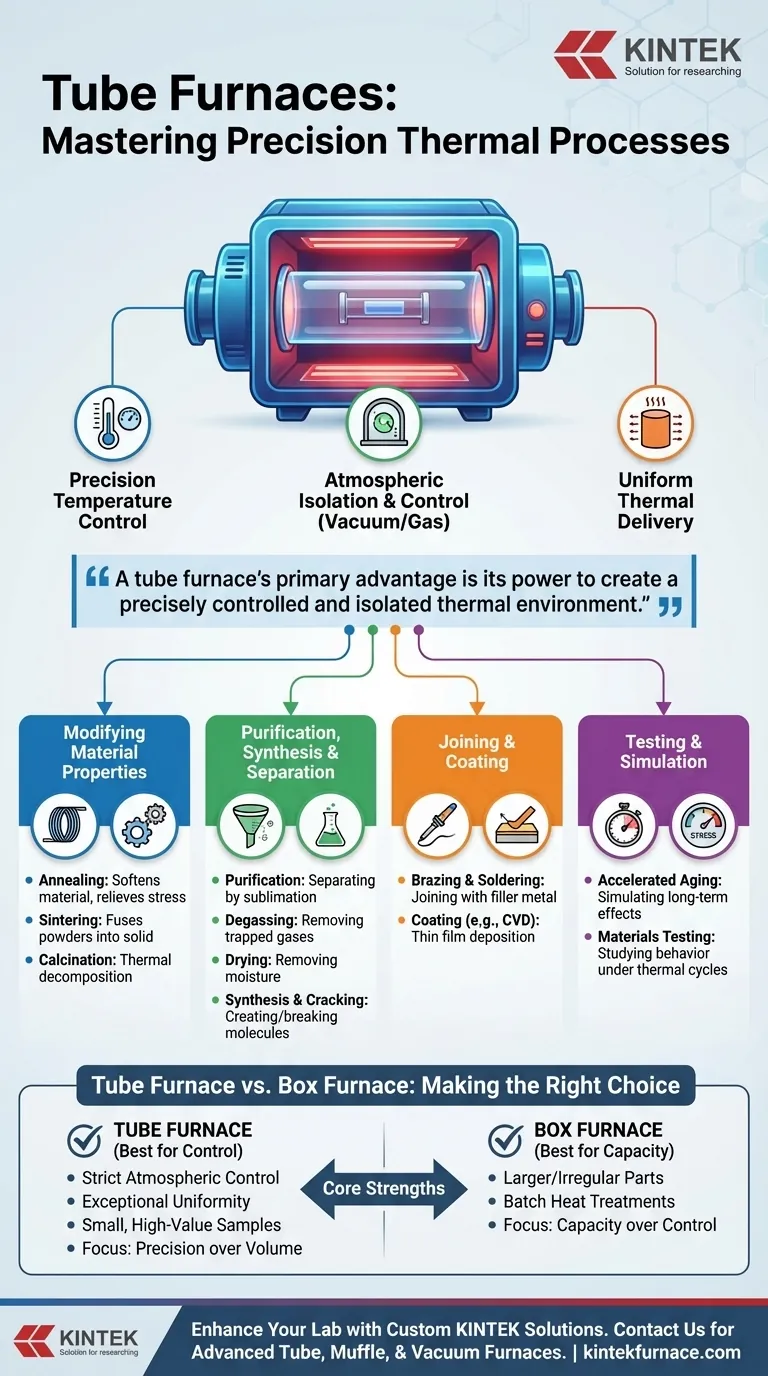

The Core Capabilities of a Tube Furnace

The function of a tube furnace is defined by three key characteristics that make it ideal for specific, high-precision tasks.

Precision Temperature Control

Tube furnaces are engineered for exceptional thermal accuracy. They can ramp up to a specific setpoint, hold that temperature with minimal deviation, and cool down in a controlled manner, which is critical for repeatable scientific and manufacturing outcomes.

Atmospheric Isolation and Control

The defining feature of a tube furnace is its process tube, which isolates the sample from the ambient environment. This allows for processing under vacuum to remove contaminants or for the introduction of specific inert or reactive gases, preventing unwanted reactions like oxidation.

Uniform Thermal Delivery

The cylindrical geometry of the heating chamber and process tube ensures that the sample is heated evenly from all sides. This outstanding temperature uniformity is essential for processes like annealing or sintering, where even slight temperature variations can compromise the final material properties.

Key Thermal Processes Explained

The unique capabilities of a tube furnace enable a variety of specialized applications across research and industry.

Modifying Material Properties

These processes use heat to fundamentally change the physical or chemical structure of a material.

- Annealing: Heating a material and allowing it to cool slowly, which softens it, increases ductility, and relieves internal stresses.

- Sintering: Heating powdered materials below their melting point to fuse the particles together into a solid, dense object.

- Calcination: Heating a solid material to high temperatures in the absence of air to induce thermal decomposition, often to remove a volatile fraction or create a more stable, phase-pure compound.

Purification, Synthesis, and Separation

These applications leverage precise temperature and atmospheric control to create, clean, or separate materials.

- Organic & Inorganic Purification: Using heat to sublimate a compound, separating it from non-volatile impurities.

- Degassing: Removing trapped or dissolved gases from a material, typically by heating it under vacuum.

- Drying: Removing moisture or other solvents from a sample in a highly controlled and clean environment.

- Synthesis & Cracking: Providing the controlled energy and environment needed to synthesize new compounds or to break down complex molecules (cracking) into simpler ones.

Joining and Coating

The controlled environment is also ideal for surface treatments and material joining.

- Brazing & Soldering: Joining two or more metal items by melting and flowing a filler metal into the joint.

- Coating: Used in processes like Chemical Vapor Deposition (CVD), where a specific atmosphere and high temperature cause volatile precursors to deposit a thin film onto a substrate.

Testing and Simulation

The repeatable and controlled nature of a tube furnace makes it an essential tool for materials science research.

- Accelerated Aging: Simulating the long-term effects of temperature on a material's stability and performance in a much shorter timeframe.

- Materials Testing: Subjecting materials to various thermal cycles to study their behavior and durability under specific conditions.

Understanding the Trade-offs: Tube Furnace vs. Box Furnace

While a tube furnace is a powerful tool, it's not always the right choice. Understanding its counterpart, the box furnace, is key to selecting the correct instrument.

When to Choose a Tube Furnace

A tube furnace is the superior choice when your process demands strict atmospheric control (vacuum or specific gas), exceptional temperature uniformity, or when working with small, high-value samples. Its design is optimized for precision over volume.

When a Box Furnace Is a Better Fit

A box furnace, with its larger, rectangular chamber, is better suited for processing larger or irregularly shaped parts. It is the go-to instrument for batch heat treatments like hardening, tempering, or stress-relieving bulk materials where the need for atmospheric control is less critical.

Making the Right Choice for Your Application

Selecting the proper furnace requires aligning the instrument's core strengths with your primary objective.

- If your primary focus is material synthesis, purification, or coating: The absolute atmospheric control of a tube furnace is non-negotiable for preventing contamination and enabling specific chemical reactions.

- If your primary focus is modifying the properties of small, sensitive parts: The superior temperature uniformity of a tube furnace ensures consistent and repeatable results across the entire sample.

- If your primary focus is heat-treating larger batches or bulky objects: The greater capacity and accessibility of a box furnace make it the more practical and efficient choice.

Ultimately, understanding that a tube furnace excels at precision control and a box furnace excels at capacity will guide you to the most effective process outcome.

Summary Table:

| Process Type | Key Applications | Key Benefits |

|---|---|---|

| Modifying Material Properties | Annealing, Sintering, Calcination | Uniform heating, stress relief, material densification |

| Purification, Synthesis, and Separation | Organic/Inorganic purification, Degassing, Drying | Atmospheric control, contamination prevention, precise temperature |

| Joining and Coating | Brazing, Soldering, CVD coating | Controlled environment for thin films and strong joints |

| Testing and Simulation | Accelerated aging, Materials testing | Repeatable results, simulation of long-term effects |

Ready to enhance your lab's capabilities with a custom tube furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored to your unique needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your specific experimental requirements. Whether you're in research, materials science, or industrial processing, our solutions ensure precise temperature control, atmospheric isolation, and uniform heating for superior results. Contact us today to discuss how we can optimize your thermal processes and drive your innovations forward!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions