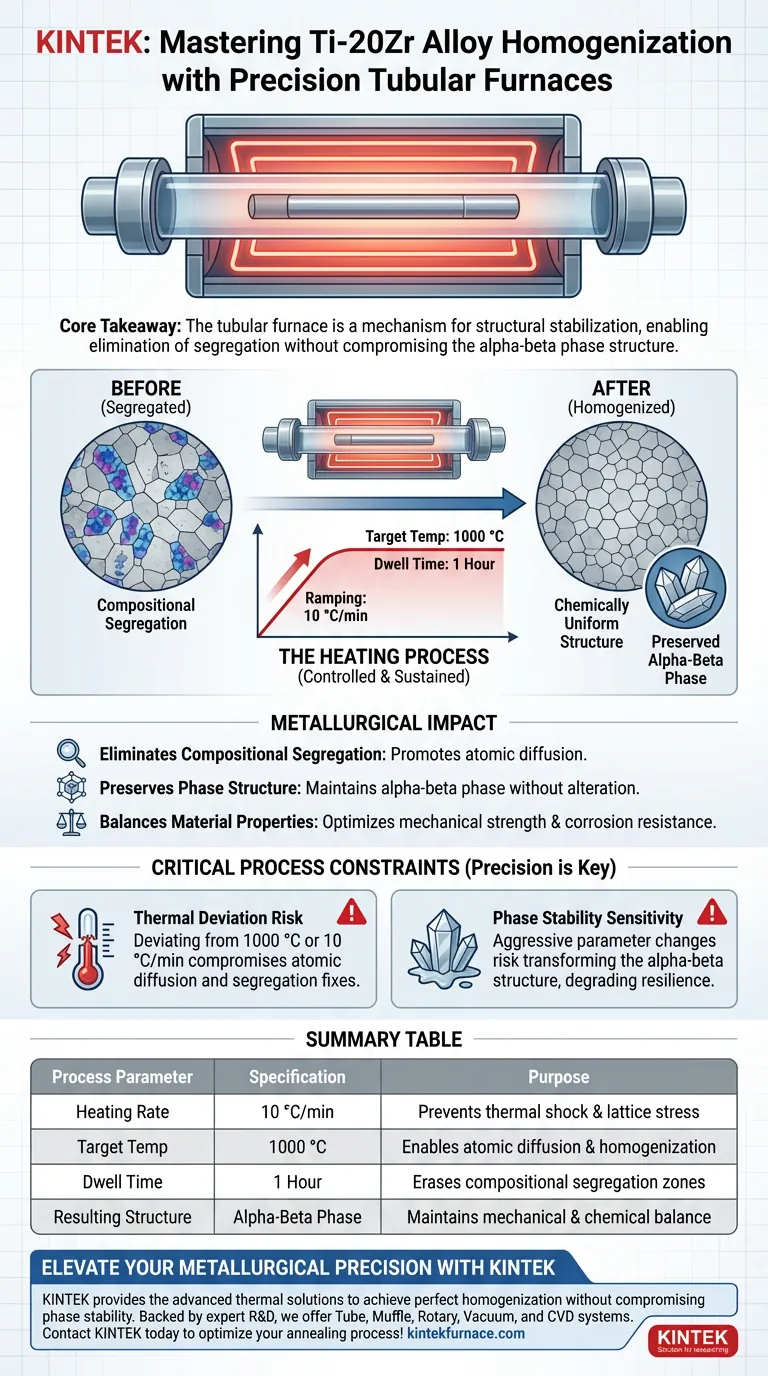

A tubular furnace functions as a precision thermal instrument used to eliminate compositional irregularities in Ti-20Zr alloys following the melting process. Specifically, it executes a rigorous heating profile—ramping at 10 °C/min to a target of 1000 °C and holding for one hour—to facilitate atomic diffusion.

Core Takeaway The tubular furnace is not merely a heating source; it is a mechanism for structural stabilization. By providing a controlled thermal environment, it enables the elimination of segregation defects inherent to melting, ensuring the alloy achieves a critical balance of mechanical strength and corrosion resistance without compromising its alpha-beta phase structure.

The Mechanics of the Heating Process

Controlled Heating Rates

The tubular furnace is utilized to apply a strictly regulated heating rate of 10 °C/min.

This controlled ramp-up is essential to gradually introduce thermal energy into the material. It prevents thermal shock and prepares the alloy lattice for the diffusion process.

Sustained High-Temperature Dwell

Once the furnace reaches the target temperature of 1000 °C, it maintains this environment for exactly one hour.

This holding period is the critical phase where the actual homogenization occurs. It provides the necessary time and energy for atoms to migrate and redistribute evenly throughout the material.

The Metallurgical Impact

Eliminating Compositional Segregation

During the initial melting of Ti-20Zr alloys, chemical segregation often occurs, leading to uneven material properties.

The tubular furnace utilizes thermal energy to promote atomic diffusion. This process effectively erases these segregation zones, resulting in a chemically uniform structure.

Preserving Phase Structure

A unique advantage of this specific thermal profile is its impact on the alloy's phase composition.

The furnace homogenizes the structure without altering the alpha-beta phase structure. This retention is vital for maintaining the alloy's intended physical characteristics.

Balancing Material Properties

The ultimate output of this furnace-controlled process is a material that performs well across conflicting metrics.

By homogenizing the structure while keeping phases intact, the process achieves an optimal balance between mechanical strength and corrosion resistance.

Critical Process Constraints

The Risk of Thermal Deviation

The effectiveness of the homogenization process relies entirely on the precision of the tubular furnace.

Deviating from the 1000 °C setpoint or the 10 °C/min rate can compromise the results. Insufficient heat may fail to induce enough atomic diffusion to fix segregation issues.

Phase Stability Sensitivity

The primary reference indicates that this specific process preserves the alpha-beta structure.

Implied in this is a trade-off: aggressive changes to the furnace parameters could inadvertently transform the phase structure, potentially degrading the material's mechanical or chemical resilience.

Making the Right Choice for Your Goal

To maximize the utility of a tubular furnace for Ti-20Zr alloys, consider your specific metallurgical objectives:

- If your primary focus is Structural Uniformity: Ensure the furnace can maintain the 1000 °C dwell time precisely to facilitate complete atomic diffusion and eliminate segregation.

- If your primary focus is Property Balance: Adhere strictly to the 10 °C/min heating rate to homogenize the material without disrupting the critical alpha-beta phase structure.

Success in processing Ti-20Zr lies in the disciplined adherence to these precise thermal parameters.

Summary Table:

| Process Parameter | Specification | Purpose |

|---|---|---|

| Heating Rate | 10 °C/min | Prevents thermal shock & lattice stress |

| Target Temp | 1000 °C | Enables atomic diffusion & homogenization |

| Dwell Time | 1 Hour | Erases compositional segregation zones |

| Resulting Structure | Alpha-Beta Phase | Maintains mechanical & chemical balance |

Elevate Your Metallurgical Precision with KINTEK

Compositional uniformity is the cornerstone of high-performance Ti-20Zr alloys. KINTEK provides the advanced thermal solutions necessary to achieve perfect homogenization without compromising phase stability.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or production requirements. Whether you are conducting critical research or scaling industrial alloys, our high-temperature furnaces deliver the precision your materials demand.

Ready to optimize your annealing process? Contact KINTEK today to consult with our experts!

Visual Guide

References

- Iosif Hulka, Julia Claudia Mirza Rosca. Electrochemical Study and Mechanical Properties of Ti-Zr Alloy for Biomedical Applications. DOI: 10.3390/cryst14060493

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is high-pressure resistance a critical requirement for SCWG tube reactors? Ensuring Success in Microplastic Energy

- What makes the multi gradient experimental tube furnace capable of creating temperature gradients? Unlock Precise Thermal Control for Your Experiments

- Why is a high-precision tube furnace required during Fe-Mn catalyst synthesis? Control Morphology and CNF Quality

- How is an electric tubular furnace defined and what are its main functions? Unlock Precision Heating for Your Lab

- Why is it necessary to maintain a vacuum inside the tube? To Enable Controlled Electron Flow

- What role do vacuum tube furnaces play in ceramic and glass manufacturing? Unlock High-Purity, Dense Materials

- What are the configuration options available for split tube furnaces? Customize for Precise Thermal and Atmospheric Control

- Why are sealed quartz tubes required for Au-Seeded TiO2 nanowires? Ensure Vapor-Phase Stability and VLS Growth