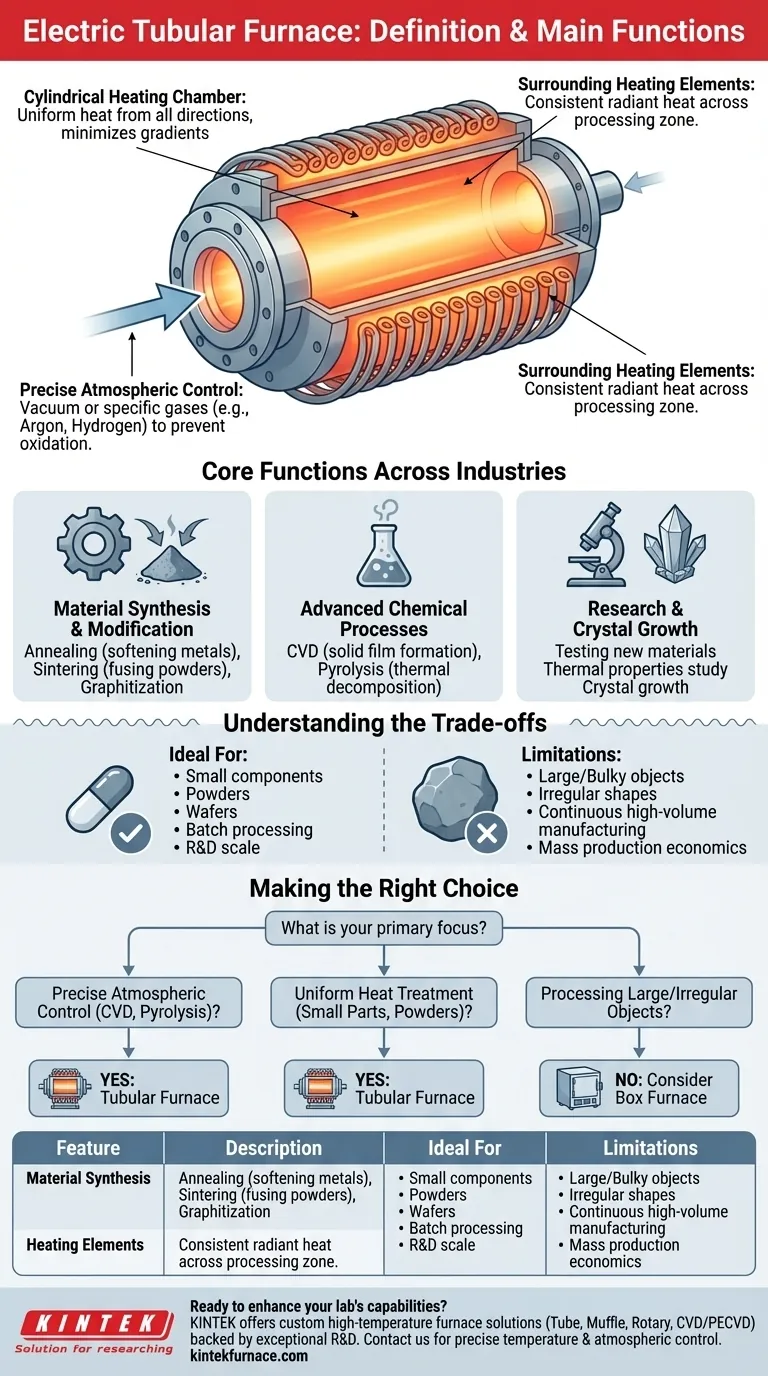

At its core, an electric tubular furnace is a high-temperature heating device defined by its cylindrical, tube-shaped chamber. This chamber, surrounded by heating elements, is specifically engineered to provide exceptionally uniform heat and precise temperature control for materials placed inside it.

The true value of a tubular furnace isn't just its ability to get hot, but its unique design that enables unparalleled control over a material's thermal and atmospheric environment, making it an essential tool for advanced research and specialized manufacturing.

The Defining Principle: Uniformity and Control

The effectiveness of a tubular furnace stems directly from its fundamental design. Every component is optimized for creating a highly stable and repeatable processing environment.

The Cylindrical Heating Chamber

The tube is the heart of the system. Its cylindrical geometry ensures that a sample placed in the center receives thermal energy evenly from all directions, minimizing temperature gradients and hot spots that can ruin sensitive processes.

Surrounding Heating Elements

Heating elements, typically made of high-resistance wire or ceramics, are wrapped around the exterior of the tube. This configuration delivers consistent, radiant heat across the entire length of the processing zone for maximum temperature uniformity.

Enabling Precise Atmospheric Control

The tube design is uniquely suited for controlling the atmosphere around the sample. The ends of the tube can be sealed with flanges, allowing operators to create a vacuum or introduce a continuous flow of specific gases, such as inert argon or reactive hydrogen. This is critical for preventing oxidation or facilitating specific chemical reactions.

Core Functions Across Industries

While versatile, a tubular furnace excels at specific high-temperature tasks that demand precision. Its applications are foundational in materials science, chemistry, and engineering.

Material Synthesis and Modification

Many processes use heat to alter a material's internal structure and properties. A tubular furnace is ideal for annealing (softening metals), sintering (fusing powders into a solid mass), and graphitization (converting carbon-containing materials into graphite).

Advanced Chemical Processes

The furnace provides the controlled energy and atmosphere needed for complex chemical reactions. These include Chemical Vapor Deposition (CVD), where gases react to form a solid thin film on a substrate, and pyrolysis, the thermal decomposition of materials in an inert atmosphere.

Research and Crystal Growth

In laboratory settings, these furnaces are used for a wide range of experiments on small samples. Their efficiency and rapid heating capabilities make them perfect for testing new materials, studying thermal properties, and performing specialized tasks like crystal growth.

Understanding the Trade-offs

No single tool is perfect for every job. The specialization of a tubular furnace comes with inherent limitations that are important to recognize.

Sample Size and Geometry

The primary constraint is the tube's diameter and length. This design is perfect for small components, powders, wafers, or cylindrical samples but is completely unsuitable for large, bulky, or irregularly shaped objects.

Batch Processing Focus

Most standard tubular furnaces are designed for batch processing, where one sample or a small group of samples is loaded, processed, and then removed. They are not inherently built for continuous, high-volume manufacturing lines.

Cost-Effectiveness is Scale-Dependent

While highly cost-effective for heating small samples in a research or prototype setting, the economics change at a larger scale. For mass production of heat-treated parts, other designs like conveyor or box furnaces may offer a lower cost per unit.

Making the Right Choice for Your Process

Selecting the correct furnace depends entirely on the requirements of your material and the desired outcome.

- If your primary focus is precise atmospheric control for sensitive reactions (like CVD or pyrolysis): The sealed-tube design makes a tubular furnace the superior choice.

- If your primary focus is uniform heat treatment of small parts or powders (like annealing or sintering): The cylindrical chamber provides the temperature consistency required for high-quality results.

- If your primary focus is processing large or irregularly shaped objects: You should investigate an alternative like a box or muffle furnace, which offers a larger, more accessible chamber.

Ultimately, a tubular furnace is a specialized instrument chosen when precision, uniformity, and atmospheric control are more critical than sample size or throughput.

Summary Table:

| Feature | Description |

|---|---|

| Definition | High-temperature device with a cylindrical tube chamber for uniform heating and precise control. |

| Key Functions | Material synthesis (annealing, sintering), chemical processes (CVD, pyrolysis), and research (crystal growth). |

| Ideal For | Small samples, powders, and processes requiring atmospheric control (e.g., inert or reactive gases). |

| Limitations | Not suitable for large or irregular objects; typically batch processing only. |

Ready to enhance your laboratory's capabilities with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Whether you're in materials science, chemistry, or engineering, we can help you achieve precise temperature control and atmospheric management. Contact us today to discuss how we can support your research and innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety