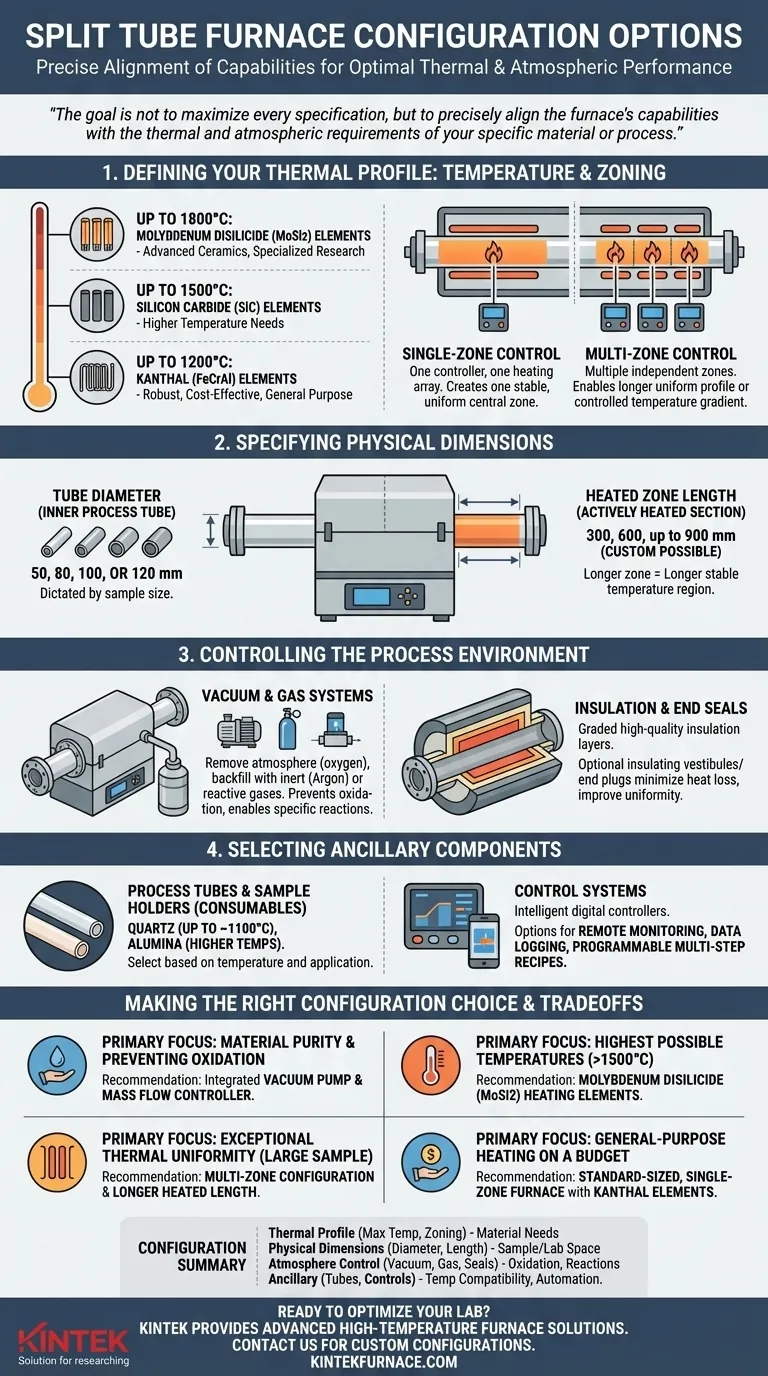

Essentially, split tube furnace configuration revolves around five key areas: thermal performance, physical dimensions, atmosphere control, process accessories, and control systems. The primary options allow you to specify the maximum temperature, the size of the heated zone, the number of independent heating zones, and whether the furnace can operate under vacuum or a controlled gas environment.

The goal of furnace configuration is not to maximize every specification, but to precisely align the furnace's capabilities with the thermal and atmospheric requirements of your specific material or process. A mismatched configuration leads to inefficient operation, poor results, and unnecessary cost.

1. Defining Your Thermal Profile: Temperature and Zoning

The core function of the furnace is to deliver a precise thermal profile. Your first decisions will be about how hot it needs to get and how uniform that heat must be.

Maximum Operating Temperature

The furnace's peak temperature dictates the type of heating element used. This is a fundamental choice that impacts cost and application range.

- Up to 1200°C: These furnaces typically use Kanthal (FeCrAl) alloy elements, which are robust and cost-effective for general-purpose applications.

- Up to 1500°C: Furnaces in this range require Silicon Carbide (SiC) elements.

- Up to 1800°C: Reaching the highest temperatures requires Molybdenum Disilicide (MoSi2) elements, which are necessary for advanced ceramics and specialized material research.

Single-Zone vs. Multi-Zone Control

This choice determines the level of control you have over the temperature profile along the length of the tube.

- A single-zone configuration has one controller and heating element array. It is designed to create one stable, uniform temperature zone in the center of the furnace.

- A multi-zone configuration has multiple independent heating zones and controllers. This allows you to create a longer, more precise uniform temperature profile or to intentionally create a temperature gradient across your sample.

2. Specifying Physical Dimensions

The physical size of the furnace must accommodate your sample and fit within your facility.

Tube Diameter

The inner diameter of the process tube that the furnace accommodates is a critical dimension. Standard options typically include 50, 80, 100, or 120 mm. The correct choice is dictated by the size of the sample you need to process.

Heated Zone Length

This dimension defines the length of the section that is actively heated. Standard lengths are often 300 mm or 600 mm, though custom lengths up to 900 mm or more can be specified. A longer heated zone is required to achieve a longer region of stable, uniform temperature.

3. Controlling the Process Environment

Many modern processes cannot be performed in ambient air. Atmosphere control is a critical configuration option for preventing oxidation and enabling specific chemical reactions.

Vacuum and Gas Systems

Furnaces can be equipped with flanges, seals, and ports to connect a vacuum system and a gas flow controller. This allows you to remove the atmosphere (oxygen) and backfill the process tube with an inert gas like argon or a reactive gas as required by your experiment.

Insulation and End Seals

For maximum thermal efficiency and stable atmosphere control, furnaces are built with graded layers of high-quality insulation. Optional insulating vestibules or end plugs can be added to the ends of the tube to minimize heat loss and improve temperature uniformity.

Understanding the Trade-offs

Choosing a configuration involves balancing performance with cost and complexity. There is no single "best" furnace.

Temperature vs. Element Cost

Higher maximum temperatures require more expensive heating elements (MoSi2) and more advanced insulation. Over-specifying the temperature capability significantly increases the initial cost of the furnace.

Multi-Zone Complexity vs. Single-Zone Simplicity

While a multi-zone furnace offers superior control, it is more complex to program and more expensive than a single-zone model. For applications where a simple, stable heat treatment is all that's needed, a single-zone furnace is a more reliable and cost-effective choice.

Customization vs. Standardization

Standard dimensions for tube diameter and heated length offer the best value and shortest lead times. Requesting custom dimensions or power ratings is always possible but will increase both the cost and the time to delivery.

4. Selecting Ancillary Components

Beyond the furnace body itself, key accessories and systems complete the setup.

Process Tubes and Sample Holders

The furnace heats the process tube, which contains your sample. These are consumable items and must be selected based on your temperature and application. Common materials are quartz (for use up to ~1100°C) and high-purity alumina (for higher temperatures).

Control Systems

Modern furnaces come with intelligent digital controllers. Standard configurations allow for precise temperature regulation, but you can opt for advanced systems that feature remote monitoring, data logging, and programmable multi-step recipes to automate complex thermal cycles.

Making the Right Configuration Choice

Your final specification should be a direct reflection of your primary objective.

- If your primary focus is material purity and preventing oxidation: Prioritize a furnace package with an integrated vacuum pump and mass flow controller for gas delivery.

- If your primary focus is achieving the highest possible temperatures (above 1500°C): You must select a furnace with Molybdenum Disilicide (MoSi2) heating elements.

- If your primary focus is exceptional thermal uniformity over a large sample: A multi-zone configuration with a longer heated length is the correct architecture.

- If your primary focus is general-purpose heating on a budget: A standard-sized, single-zone furnace with Kanthal elements provides the most reliable and economical solution.

A properly configured furnace is an empowering tool that delivers reliable and repeatable results for years to come.

Summary Table:

| Configuration Area | Key Options | Key Considerations |

|---|---|---|

| Thermal Profile | Max Temperature (up to 1800°C), Single/Multi-Zone | Choose based on material needs; higher temps and multi-zone increase cost and complexity |

| Physical Dimensions | Tube Diameter (50-120mm), Heated Zone Length (300-900mm) | Match to sample size and lab space; custom sizes add cost and lead time |

| Atmosphere Control | Vacuum/Gas Systems, Insulation/Seals | Essential for oxidation prevention and specific reactions; improves uniformity and efficiency |

| Ancillary Components | Process Tubes (e.g., Quartz, Alumina), Control Systems | Select for temperature compatibility; advanced controls enable automation and data logging |

Ready to optimize your lab with a tailored split tube furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your material processing with reliable, efficient, and custom-configured furnaces!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide