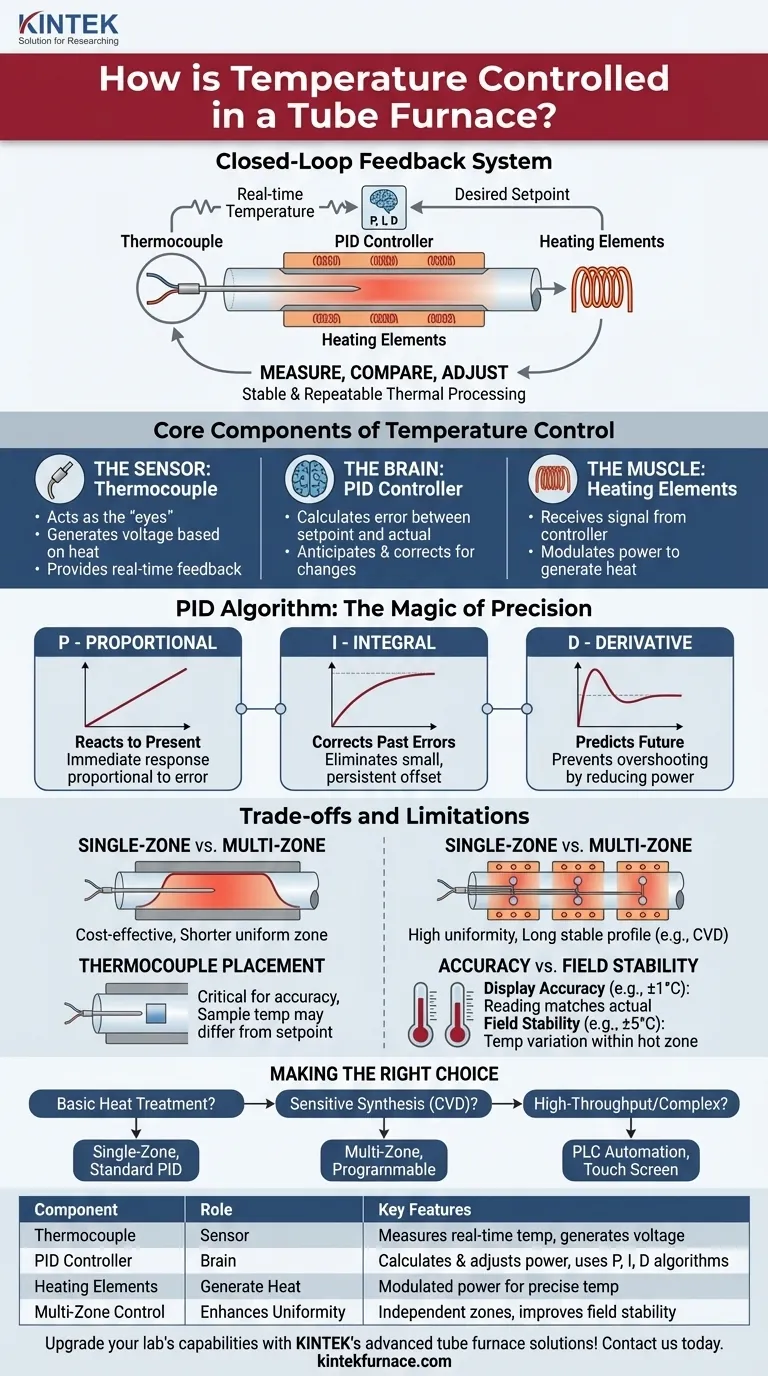

At its core, a tube furnace controls temperature through a closed-loop feedback system. A sensor, most often a thermocouple, constantly measures the temperature inside the furnace. This measurement is sent to a dedicated controller, which compares the actual temperature to your desired setpoint and precisely adjusts the power sent to the heating elements to maintain that target.

The entire control process relies on a simple yet powerful loop: measure, compare, and adjust. A thermocouple measures the real-time temperature, a controller compares it to your target, and it adjusts the heating power to eliminate any difference, ensuring stable and repeatable thermal processing.

The Core Components of Temperature Control

A tube furnace's temperature control system is built on three fundamental components working in unison. Understanding the role of each is key to appreciating how precision is achieved.

The Sensor: The Thermocouple

A thermocouple acts as the "eyes" of the furnace. It is a robust sensor made of two different metals joined at one end. When this junction is heated, it generates a tiny voltage that corresponds directly to the temperature. This signal provides the crucial, real-time feedback for the entire system.

The Brain: The PID Controller

The signal from the thermocouple is fed into a temperature controller. The vast majority of modern furnaces use a PID (Proportional-Integral-Derivative) controller, which serves as the "brain" of the operation. It continuously calculates the difference—or "error"—between the measured temperature and your setpoint.

The Muscle: The Heating Elements

Based on the calculations from the PID controller, a signal is sent to a power switching device (like an SCR or relay). This device precisely modulates the amount of electrical power delivered to the heating elements surrounding the furnace tube, which in turn generates the heat.

How the System Achieves Precision: The PID Algorithm

The "magic" of a modern furnace's stability and accuracy lies in the PID algorithm. It doesn't just turn the heat on or off; it intelligently anticipates and corrects for changes to prevent overshooting or undershooting the target temperature.

The "P" (Proportional): Reacting to the Present

The proportional component provides an immediate response that is directly proportional to the current temperature error. The larger the difference between the setpoint and the actual temperature, the more power the controller applies.

The "I" (Integral): Correcting for Past Errors

The integral component looks at the accumulated error over time. If the furnace is consistently just slightly below the setpoint, this component will gradually increase the power output to eliminate that small, persistent error and bring the system exactly to the target.

The "D" (Derivative): Predicting the Future

The derivative component looks at the rate of temperature change. As the furnace temperature rapidly approaches the setpoint, this component reduces the power output to prevent overshooting. It effectively "hits the brakes" to ensure a smooth arrival at the target temperature without wide fluctuations.

Understanding the Trade-offs and Limitations

While modern control systems are highly effective, their performance is subject to physical and design constraints. Acknowledging these is crucial for obtaining valid results.

Single-Zone vs. Multi-Zone Control

A standard single-zone furnace uses one thermocouple and one set of heating elements. While cost-effective, this design inherently creates a shorter uniform hot zone in the center of the tube, with temperatures dropping off towards the ends.

For applications demanding high uniformity over a longer length, such as Chemical Vapor Deposition (CVD), multi-zone furnaces are used. These have multiple, independently controlled heating zones and thermocouples, allowing the system to create a much longer and more stable flat temperature profile.

Thermocouple Placement is Critical

The controller only knows the temperature at the precise location of the thermocouple tip. If the thermocouple is placed far from your sample, the temperature your sample experiences may be different from the controller's setpoint. Proper placement is essential for process accuracy.

Accuracy vs. Field Stability

Furnace specifications often list display accuracy (e.g., ±1°C) and temperature field stability (e.g., ±5°C). The display accuracy refers to how closely the controller's reading matches the thermocouple's actual temperature. Field stability, the more critical metric, describes the actual temperature variation within the uniform hot zone of the furnace during operation.

Making the Right Choice for Your Process

The sophistication of the control system you need is dictated entirely by your application's requirements for precision and repeatability.

- If your primary focus is basic heat treatment or annealing: A single-zone furnace with a standard, self-tuning PID controller provides reliable and cost-effective performance.

- If your primary focus is sensitive material synthesis like CVD or crystal growth: A multi-zone furnace with a programmable controller is essential for achieving the required temperature uniformity and repeatable process ramps.

- If your primary focus is high-throughput production or complex recipes: A system with PLC automation and a touch screen interface will offer the best control, data logging, and ease of use for complex, multi-step processes.

Understanding these control principles empowers you to not only select the right equipment but also to troubleshoot and optimize your thermal processes effectively.

Summary Table:

| Component | Role in Temperature Control | Key Features |

|---|---|---|

| Thermocouple | Sensor that measures real-time temperature | Generates voltage based on heat, provides feedback |

| PID Controller | Brain that calculates and adjusts power | Uses proportional, integral, derivative algorithms for stability |

| Heating Elements | Generate heat based on controller signals | Modulated power for precise temperature maintenance |

| Multi-Zone Control | Enhances uniformity in long tubes | Independent zones for applications like CVD, improves field stability |

Upgrade your lab's capabilities with KINTEK's advanced tube furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored to your needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization to meet unique experimental requirements. Whether you're in material synthesis, annealing, or high-throughput production, our precise temperature control systems ensure reliable, repeatable results. Contact us today to discuss how we can optimize your thermal processes and boost efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety