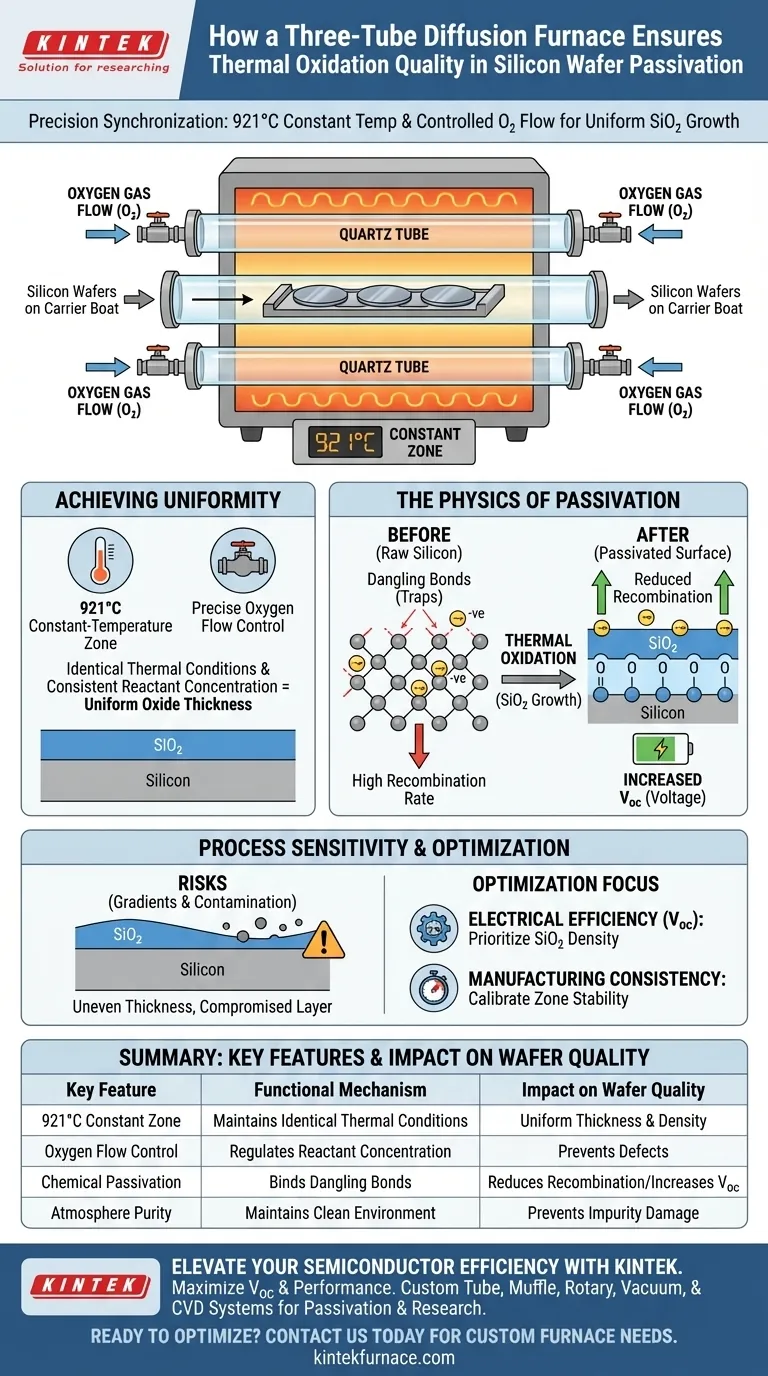

The quality of thermal oxidation layers in a three-tube diffusion furnace is ensured by the precise synchronization of oxygen gas flow and high-precision temperature regulation. By maintaining a strict constant-temperature zone, typically around 921°C, the system grows a dense, uniformly thick silicon dioxide (SiO2) layer that is critical for wafer performance.

Core Insight: The primary value of this furnace is not just heating, but chemical "passivation." By creating a uniform oxide barrier, the furnace effectively neutralizes surface defects, preventing electron loss and directly increasing the battery's open-circuit voltage (Voc).

Achieving Layer Uniformity

The Constant-Temperature Zone

The furnace relies on an extended constant-temperature zone to ensure every part of the silicon wafer is exposed to identical thermal conditions.

Operating at high temperatures, such as the 921°C benchmark, creates the ideal environment for stable oxide growth.

Controlling Gas Flow

Uniformity is further guaranteed by the strict regulation of oxygen gas flow into the tube.

This control ensures that the reactant concentration is consistent across the wafer surface, preventing variations in the thickness of the silicon dioxide layer.

The Physics of Passivation

Fixing "Dangling Bonds"

Raw silicon surfaces contain atomic defects known as "dangling bonds," which are essentially broken chemical connections.

The thermal oxidation process uses the grown SiO2 layer to chemically bind with these defects. This process is known as passivation.

Reducing Surface Recombination

When dangling bonds are left unchecked, they act as traps for charge carriers, leading to a high "surface recombination rate."

By passivating the surface, the furnace drastically lowers this recombination rate, ensuring that generated electrons are collected rather than lost.

Impact on Voltage (Voc)

The direct result of lower recombination is an increase in the open-circuit voltage (Voc).

This metric is essential for the overall efficiency of the device, making the quality of the thermal oxidation layer a determining factor in final battery performance.

Understanding Process Sensitivity

The Risk of Thermal Gradients

The effectiveness of the passivation layer is entirely dependent on the stability of the temperature zone.

Any fluctuation or gradient within the "constant" zone will lead to uneven oxide thickness, compromising the layer's density and protective qualities.

Purity and Contamination

While the diffusion process introduces oxygen intentionally, the environment must remain free of unwanted contaminants.

Just as vacuum furnaces are used in other contexts to prevent corrosion and impurity, the diffusion furnace must maintain a clean environment to ensure the SiO2 layer remains pure and structurally sound.

Optimizing for Device Performance

To maximize the benefits of a three-tube diffusion furnace, your operational focus should align with your specific efficiency goals.

- If your primary focus is Electrical Efficiency (Voc): Prioritize the density of the SiO2 layer to ensure maximum neutralization of dangling bonds.

- If your primary focus is Manufacturing Consistency: Focus on calibrating the length and stability of the constant-temperature zone to guarantee uniform thickness across all wafers.

Ultimately, the three-tube diffusion furnace transforms raw silicon into a high-efficiency component by turning a delicate surface chemical reaction into a controlled, repeatable industrial process.

Summary Table:

| Key Feature | Functional Mechanism | Impact on Wafer Quality |

|---|---|---|

| 921°C Constant Zone | Maintains identical thermal conditions across the tube | Ensures uniform oxide thickness and density |

| Oxygen Flow Control | Regulates reactant concentration during growth | Prevents thickness variations and layer defects |

| Chemical Passivation | Binds dangling bonds on silicon surfaces | Reduces surface recombination and increases Voc |

| Atmosphere Purity | Maintains a clean, controlled environment | Prevents impurities from compromising the SiO2 structure |

Elevate Your Semiconductor Efficiency with KINTEK

Maximize your device performance and open-circuit voltage (Voc) with KINTEK’s advanced thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems, all customizable to your specific laboratory or industrial high-temperature needs. Whether you require absolute temperature stability for passivation or high-purity environments for material research, our furnaces provide the consistency your process demands.

Ready to optimize your thermal oxidation process? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Nurul Aqidah Mohd Sinin, Mohd Adib Ibrahim. Electrical performance for in-situ doping of phosphorous in silver paste screen-printed contact on p-type silicon solar cell. DOI: 10.61435/ijred.2025.60822

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What design features contribute to the durability and safety of modern lab tube furnaces? Ensuring Long-Term Reliability and Operator Protection

- What are the space and footprint considerations for vertical and horizontal tube furnaces? Optimize Your Lab Layout

- How does the industrial tube furnace contribute to Fe-N-C catalyst synthesis? Master High-Temperature Carbonization

- How does a lab tube furnace differ from a box furnace? A Guide to Choosing the Right Thermal Processing Tool

- What role do multi zone tube furnaces play in new energy research? Unlock Precise Thermal Control for Innovation

- How do you rejuvenate vacuum tubes? A Last-Resort Guide to Salvaging Rare Components

- How does the horizontal design of these furnaces benefit large volume processing? Boost Efficiency and Uniformity

- What is the purpose of using a high-temperature tube furnace during FePt annealing? Achieve the L1₀ Magnetic Phase