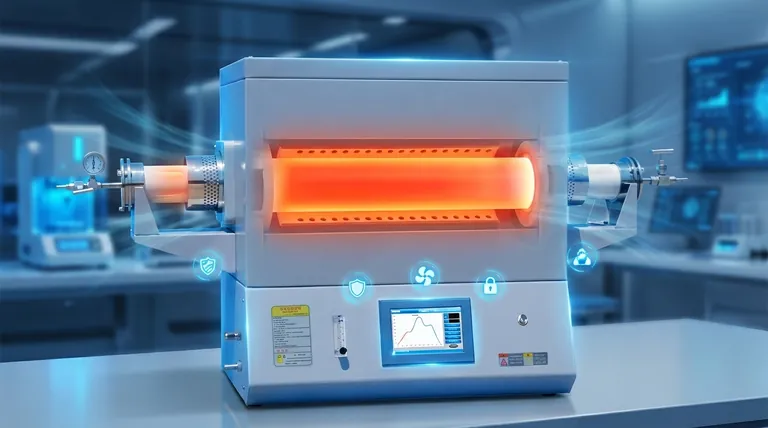

At their core, modern lab tube furnaces achieve durability and safety through a synthesis of three critical design elements: advanced heat-resistant materials, intelligent cooling systems, and automated safety interlocks. These features work in concert to ensure long-term operational stability while actively protecting both the user and the equipment from abnormal conditions.

The key takeaway is that furnace design has evolved beyond simple heat containment. True safety and durability come from an integrated system where passive design (like a cooled outer shell) and active monitoring (like automatic shut-offs) create multiple, redundant layers of protection.

The Foundation: Material Science and Structural Integrity

The long-term reliability of any furnace begins with its fundamental construction. Without a robust physical foundation, no amount of electronic control can guarantee performance.

High-Quality, Heat-Resistant Materials

The furnace body and process tubes are constructed from materials specifically chosen for high-temperature stability. This ensures they can withstand repeated thermal cycling without degrading, which is the primary factor in long-term reliability and performance consistency.

The Double-Layer Shell Design

A critical feature is the use of a double-layer steel shell. This creates an air gap between the inner high-temperature chamber and the outer casing.

This structural design serves a dual purpose: it provides physical rigidity and, more importantly, acts as the first layer of thermal insulation.

Inherent Safety: Design That Protects by Default

The safest systems are those that are safe by design, minimizing reliance on user intervention. Modern furnaces incorporate features that make safe operation the default condition.

Fan-Assisted Air Cooling

The double-shell design is almost always paired with fan cooling. A fan actively circulates air within the gap between the shells, efficiently dissipating heat.

This system is remarkably effective. It ensures the external surface temperature of the furnace remains low—often below 50°C—even when the internal temperature is well over 800°C, drastically reducing the risk of accidental burns.

Human-Centered Control Systems

Modern furnaces feature intelligent control systems, often with large touch screens and programmable segments. These systems reduce the chance of human error, a common cause of lab accidents.

By allowing users to preset and save entire heating profiles or "sintering curves," these controls ensure process repeatability and prevent accidental misconfiguration during repetitive tasks.

Active Protection: The Role of Intelligent Safety Systems

While passive design is the foundation, active electronic monitoring provides the immediate, automated response needed to prevent equipment damage and ensure operator safety during an incident.

Over-Temperature Protection

This is the most critical safety interlock. An independent sensor monitors the furnace temperature, and if it exceeds a preset safety limit, the system will automatically shut off the heating elements. This prevents catastrophic overheating and sample destruction.

Over-Pressure and Leakage Detection

For atmosphere furnaces that use controlled gases, additional protections are vital. These include sensors for over-pressure conditions and gas leakage detection, which can automatically shut down gas flow and power to prevent hazardous situations.

System Malfunction Alarms

Integrated alarms provide immediate audible and visual alerts if the system detects a malfunction, such as a broken thermocouple. This allows the operator to intervene quickly before a minor issue becomes a major failure.

Understanding the Trade-offs

Choosing a furnace requires balancing features against application-specific needs and budget.

Cost vs. Advanced Safety

Furnaces with comprehensive safety interlocks, such as gas leakage detection and multi-zone over-temperature protection, carry a higher initial cost. For low-temperature, inert atmosphere work, a simpler system may suffice.

Complexity vs. Usability

Highly programmable, multi-zone furnaces offer incredible process control but come with a steeper learning curve. A simpler, single-zone controller might be more reliable and safer in a multi-user environment where extensive training isn't feasible.

Specialized vs. General-Purpose

A furnace designed for a specific process like Chemical Vapor Deposition (CVD) will have integrated safety and control features tailored to that task. Using a general-purpose furnace for such a task might lack the necessary specialized interlocks, introducing risk.

Making the Right Choice for Your Application

Your final selection should be guided by your primary experimental or production goals.

- If your primary focus is routine, high-throughput testing: Prioritize furnaces with intuitive, programmable controls and preset recipes to minimize the risk of human error.

- If your primary focus is operator safety in a multi-user lab: The double-wall shell with fan cooling and automatic over-temperature shut-off are the most critical, non-negotiable features.

- If your primary focus is high-temperature material synthesis (>1500°C): Scrutinize the quality of the heating elements and tube materials, as these are the first points of failure at extreme temperatures.

- If you are working with reactive or flammable atmospheres: A furnace with integrated gas leakage detection, pressure relief valves, and automatic shut-offs is an absolute requirement.

By understanding these core design principles, you can confidently select a furnace that is not just a tool, but a safe and reliable partner in your work.

Summary Table:

| Key Design Feature | Primary Benefit | Impact on Safety/Durability |

|---|---|---|

| Double-Layer Steel Shell | Excellent Heat Insulation | Keeps external surfaces cool (<50°C), prevents burns |

| Fan-Assisted Air Cooling | Efficient Heat Dissipation | Reduces thermal stress, extends component life |

| Over-Temperature Protection | Automatic Shut-off | Prevents catastrophic overheating and damage |

| Gas Leakage Detection | Immediate Hazard Alert | Critical for safe operation with reactive atmospheres |

| High-Quality Heating Elements | High-Temperature Stability | Ensures consistent performance and long-term reliability |

Ready to enhance your lab's safety and efficiency? The right furnace is a reliable partner in your work. At KINTEK, our expertise ensures you get a system tailored to your specific needs.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique application requirements. Whether you need robust safety interlocks for a multi-user environment or specialized high-temperature capabilities, we can help.

Contact us today to discuss your project and discover how our durable, safe, and high-performance lab furnaces can benefit your research.

Get in touch with our experts now!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents