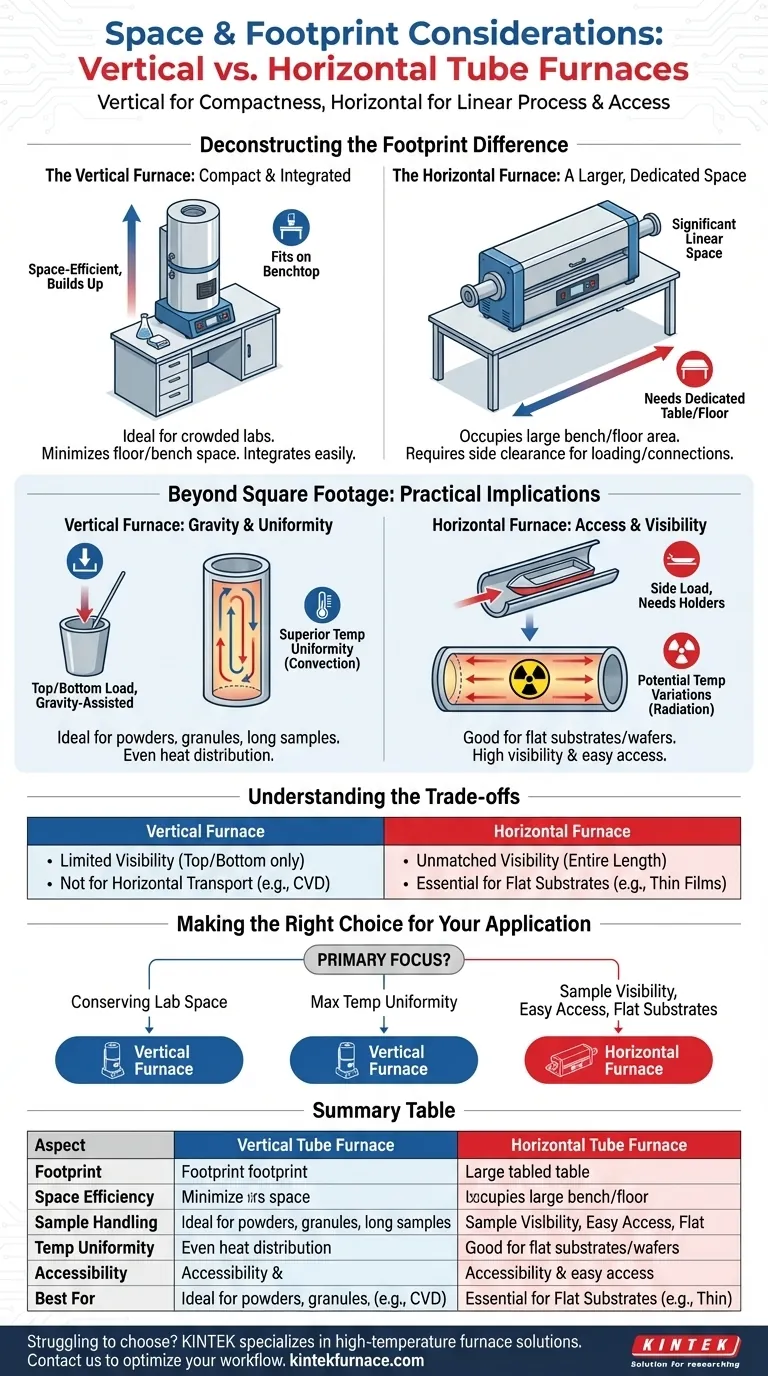

At its core, the primary difference is straightforward: vertical tube furnaces are designed for a compact, vertical footprint, while horizontal tube furnaces require a larger, linear area. Vertical models are built to maximize lab space by building upwards, often fitting on a standard benchtop. In contrast, horizontal furnaces demand more table or floor space to accommodate their length.

The choice between a vertical and horizontal tube furnace goes far beyond a simple measurement of floor space. It is a fundamental decision about workflow, sample handling, and the thermal uniformity required for your specific process.

Deconstructing the Footprint Difference

The physical orientation of the furnace dictates not only how much space it occupies but also how it integrates into your laboratory environment.

The Vertical Furnace: Compact and Integrated

A vertical tube furnace is designed with its heating chamber and tube oriented upright. This design is inherently space-efficient.

By building up instead of out, it consumes minimal bench or floor space, making it an ideal choice for crowded labs or facilities where every square foot is valuable. They can often be placed on a benchtop or integrated into larger experimental rigs without significant rearrangement.

The Horizontal Furnace: A Larger, Dedicated Space

A horizontal tube furnace, by its nature, requires a significant amount of linear space. Its length means it will occupy a large portion of a benchtop or may even require its own dedicated table or floor space.

This larger footprint is a critical logistical factor. You must ensure there is not only enough space for the furnace itself but also adequate clearance at both ends for loading, unloading, and system connections.

Beyond Square Footage: The Practical Implications

The orientation of the furnace has direct consequences on day-to-day use. The most efficient choice depends entirely on your application's specific demands for sample handling and thermal precision.

Sample Handling and Accessibility

In a vertical furnace, samples are loaded from the top or bottom, often held in a crucible or suspended. Gravity assists in keeping the sample centered, which can simplify loading, especially for powders, granules, or long, thin samples.

In a horizontal furnace, samples must be carefully pushed into the center of the tube. This can be more challenging, particularly for multiple samples or materials that cannot be easily contained, sometimes requiring a "boat" or specialized holder to position them correctly.

Temperature Uniformity

This is a critical point of differentiation. Vertical furnaces often achieve superior temperature uniformity along the sample's length. The combination of surrounding heating elements and natural convection within the vertical tube promotes an even temperature distribution.

Horizontal furnaces, while highly effective, can be more susceptible to slight temperature variations along the length of the tube. Heat primarily transfers via radiation, and without careful design and optimization, slight gradients can occur, which may be a critical factor for sensitive processes.

Understanding the Trade-offs

Neither design is universally superior. The optimal choice is a matter of balancing priorities and accepting the inherent compromises of each orientation.

The Vertical Furnace Compromise

While space-efficient, a vertical furnace can make it difficult to observe the sample during processing. Access is limited to the top and bottom ends of the tube. This design is also less suitable for applications that rely on horizontal material transport, such as zone refining or certain types of chemical vapor deposition (CVD).

The Horizontal Furnace Advantage

Despite its large footprint, the horizontal design offers unmatched accessibility and visibility. The entire length of the process tube can be more easily observed. This orientation is often essential for processes like depositing uniform thin films onto flat substrates (wafers), where a horizontal layout is non-negotiable.

Making the Right Choice for Your Application

To make a decision, move past the footprint and evaluate your primary operational goal.

- If your primary focus is conserving lab space: A vertical furnace is the unambiguous choice, allowing you to fit high-temperature capabilities into a small area.

- If your primary focus is maximum temperature uniformity for sensitive materials: A vertical furnace often provides a slight advantage due to more even heat distribution from natural convection.

- If your primary focus is sample visibility, easy access, or processing flat substrates: A horizontal furnace is almost always the necessary choice, even with its larger space requirement.

Ultimately, your decision should be driven by the needs of your process and workflow, not just the dimensions in a catalog.

Summary Table:

| Aspect | Vertical Tube Furnace | Horizontal Tube Furnace |

|---|---|---|

| Footprint | Compact, vertical, fits on benchtop | Larger, linear, requires dedicated space |

| Space Efficiency | High, ideal for crowded labs | Low, needs more floor or bench area |

| Sample Handling | Load from top/bottom, gravity-assisted | Push samples in, may need holders |

| Temperature Uniformity | Superior due to natural convection | Can have slight variations, radiation-dependent |

| Accessibility | Limited, difficult to observe during process | High, easy visibility and access |

| Best For | Space conservation, sensitive materials | Flat substrates, easy access, visibility |

Struggling to choose the right tube furnace for your lab's space and performance needs? At KINTEK, we specialize in high-temperature furnace solutions tailored to your unique requirements. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your experimental goals, whether you prioritize compact footprints, superior temperature control, or easy sample access. Don't let space constraints or process inefficiencies hold you back—contact us today to explore how our advanced furnaces can optimize your laboratory workflow and deliver reliable results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety