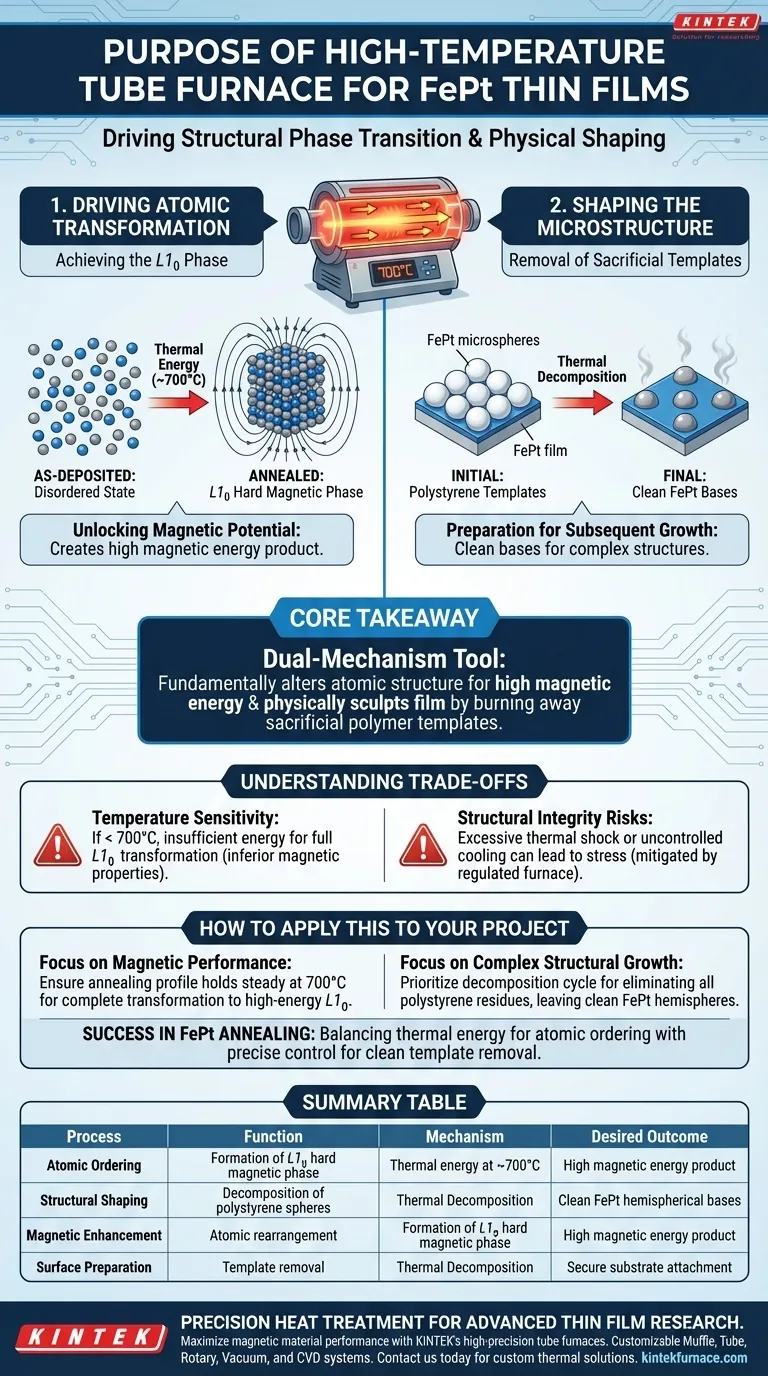

The primary function of using a high-temperature tube furnace for FePt thin films is to drive a specific structural phase transition and physically shape the material.

By maintaining a controlled thermal environment of approximately 700°C, the furnace provides the energy required to transform the film from a disordered state into the desired $L1_0$ hard magnetic phase. Simultaneously, this heat treatment serves a lithographic purpose by thermally decomposing polystyrene microsphere templates, leaving behind clean, firmly attached FePt bases ready for further structural growth.

Core Takeaway The annealing process acts as a dual-mechanism tool: it fundamentally alters the atomic structure to create a high magnetic energy product and physically sculpts the film by burning away sacrificial polymer templates.

Driving Atomic Transformation

Achieving the $L1_0$ Phase

The most critical objective of this annealing step is atomic ordering. As-deposited FePt films often exist in a chemically disordered state, which lacks the desired magnetic properties.

The Role of Thermal Energy

The tube furnace supplies the necessary thermal energy (around 700°C) to mobilize iron and platinum atoms. This allows them to migrate and rearrange into a specific tetragonal superlattice known as the $L1_0$ phase.

Unlocking Magnetic Potential

This structural rearrangement is directly responsible for the material's performance. The transition to the $L1_0$ phase creates a material with a high magnetic energy product, turning the thin film into a robust hard magnet.

Shaping the Microstructure

Removal of Sacrificial Templates

Beyond atomic ordering, the furnace performs a critical cleaning function. The FePt synthesis described relies on polystyrene microsphere templates to define the film's initial shape.

Thermal Decomposition

The high temperatures within the tube furnace cause these polystyrene spheres to decompose completely. This effectively "develops" the structure, removing the polymer without damaging the metal film.

Preparation for Subsequent Growth

Once the templates are removed, the process leaves behind FePt hemispherical bases. These bases are firmly attached to the substrate, serving as the foundational anchors for the subsequent growth of complex structures, such as magnesium-zinc spirals.

Understanding the Trade-offs

Temperature Sensitivity

The success of this process relies heavily on precise thermal regulation. If the temperature falls significantly below 700°C, the atoms may not possess enough energy to achieve the full $L1_0$ transformation, leaving the film with inferior magnetic properties.

Structural Integrity Risks

While high heat is necessary for template removal, excessive thermal shock or uncontrolled cooling can lead to stress. However, a properly regulated tube furnace mitigates this, ensuring the final hemispherical bases remain intact and adhered to the substrate.

How to Apply This to Your Project

If your primary focus is Magnetic Performance:

- Ensure your annealing profile holds steady at 700°C to guarantee the complete transformation from the disordered phase to the high-energy $L1_0$ hard magnetic phase.

If your primary focus is Complex Structural Growth:

- Prioritize the decomposition cycle to ensure all polystyrene residues are eliminated, leaving behind clean FePt hemispheres for the magnesium-zinc spiral growth step.

Success in FePt annealing requires balancing the thermal energy needed for atomic ordering with the precise control required for clean template removal.

Summary Table:

| Process Function | Mechanism | Desired Outcome |

|---|---|---|

| Atomic Ordering | Thermal energy at ~700°C | Formation of $L1_0$ hard magnetic phase |

| Structural Shaping | Decomposition of polystyrene spheres | Clean FePt hemispherical bases |

| Magnetic Enhancement | Atomic rearrangement | High magnetic energy product |

| Surface Preparation | Template removal | Secure substrate attachment for future growth |

Precision Heat Treatment for Advanced Thin Film Research

Maximize your magnetic material performance with KINTEK’s high-precision tube furnaces. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous thermal demands of $L1_0$ phase transitions and sacrificial template removal.

Whether you are a researcher or an industrial manufacturer, KINTEK provides the reliability and temperature uniformity needed for complex material synthesis. Contact us today to find your custom thermal solution and see how our lab high-temp furnaces can empower your next breakthrough.

Visual Guide

References

- Florian Peter, Peer Fischer. Degradable and Biocompatible Magnesium Zinc Structures for Nanomedicine: Magnetically Actuated Liposome Microcarriers with Tunable Release. DOI: 10.1002/adfm.202314265

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are tube furnaces made of? Choose the Right Material for Your Thermal Process

- What role does a single-zone tube furnace play in synthesizing ZnPS3? Master the Thermal Profile for Layered Materials

- What are the key advantages of using fluidized bed technology in vertical tube furnaces? Boost Efficiency and Uniformity

- Why is thermal uniformity a significant advantage of tube furnaces? Achieve Consistent Heating for Precision Processes

- What are the benefits of Tube Furnaces? Achieve Precision, Control, and Versatility in Thermal Processing

- What is the function of a double-temperature zone tube furnace in CVD synthesis of 2D epsilon-Fe2O3 nanosheets?

- How does a tube furnace ensure a controlled reaction environment? Achieve Precise Isothermal Oxidation Results

- How does a high-temperature tube furnace ensure effective conversion during MOF selenization? Optimize Your Synthesis