At their core, tube furnaces are constructed from a distinct set of high-performance materials chosen for thermal resilience and chemical stability. The main body or casing is typically made of stainless steel for durability and insulation. However, the critical component is the inner work tube, which contains the sample and is most commonly made from a ceramic like alumina, a glass like quartz, or a specialty metal alloy like Inconel.

The choice of material is not arbitrary; it is a critical decision dictated by your experiment's maximum temperature, required chemical inertness, and atmospheric conditions. The furnace's outer body provides structure and insulation, while the inner tube directly contains the reaction and must be robust enough to withstand the entire process environment.

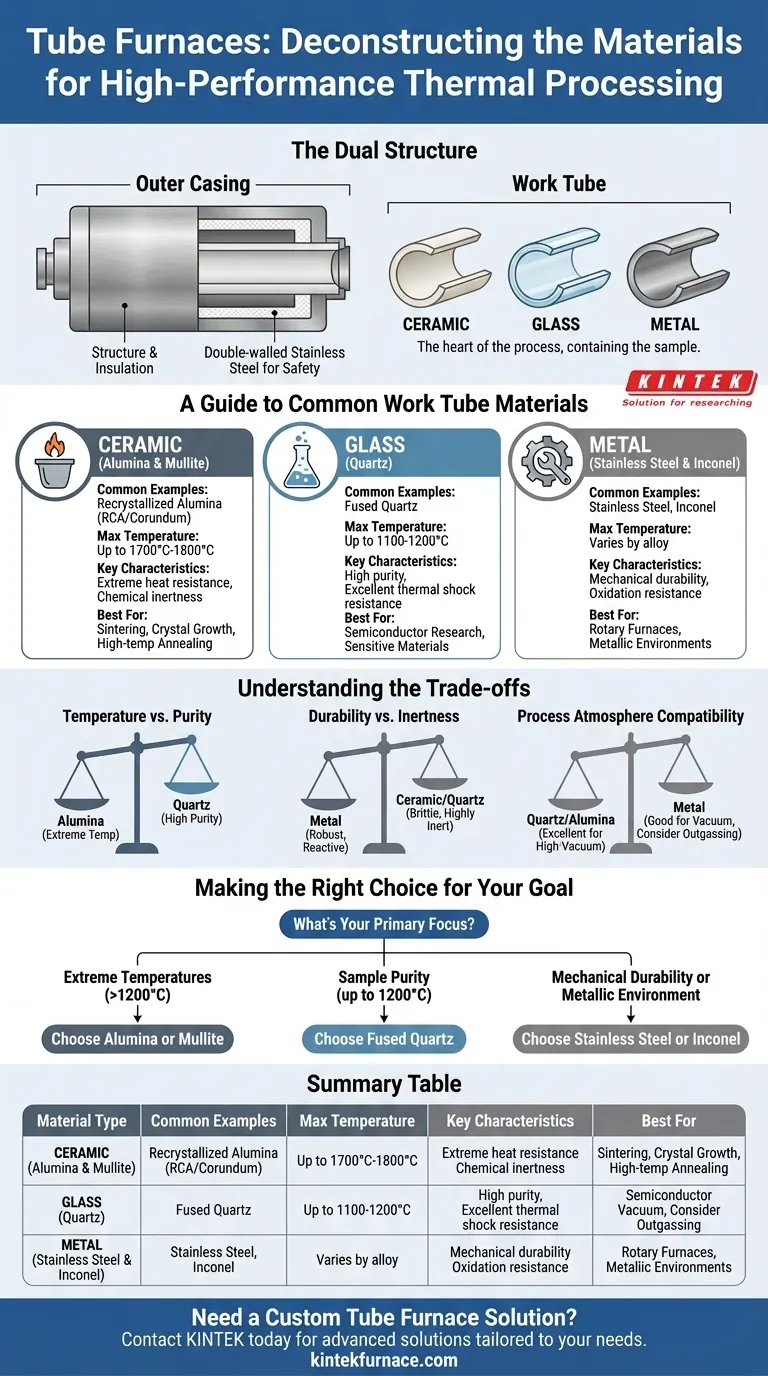

Deconstructing the Tube Furnace: Casing vs. Work Tube

To understand the furnace's construction, it's essential to distinguish between its two primary structural components. Each serves a different purpose and is made from different materials.

The Outer Casing: Structure and Insulation

The external body of a modern tube furnace is almost always constructed from stainless steel.

This material provides excellent structural durability and corrosion resistance. In many designs, a double-walled stainless steel construction is used to create an air gap, which significantly improves thermal insulation and keeps the exterior safe to touch.

The Work Tube: The Heart of the Process

The work tube is the hollow cylinder that passes through the heated center of the furnace. This is where the sample is placed and the thermal processing occurs.

The material of this tube is the single most important factor determining the furnace's capabilities, as it must withstand extreme heat, chemical reactions, and potentially high vacuum without contaminating the sample.

A Guide to Common Work Tube Materials

The selection of a work tube material is a direct function of the intended application. The three main categories are ceramics, glasses, and metals.

Ceramic Tubes (Alumina & Mullite)

Ceramic tubes are the champions of high-temperature applications. Recrystallized alumina (also called RCA or Corundum) is the most common choice.

These tubes offer the highest operational temperatures, with some capable of stable use up to 1700°C or even 1800°C. They possess excellent chemical inertness and structural integrity under extreme thermal stress, making them ideal for sintering, annealing, and crystal growth.

Glass Tubes (Quartz)

Fused quartz is an extremely common material for work tubes due to its high purity and excellent thermal shock resistance.

While its maximum temperature is lower than alumina (typically around 1100-1200°C), its superior chemical purity prevents sample contamination in sensitive processes. It is the standard for many semiconductor and advanced materials research applications. Pyrex is a less common, lower-temperature alternative.

Metal Tubes (Stainless Steel & Inconel)

Metal tubes are chosen for their mechanical durability and resistance to physical shock. They are often found in rotary tube furnaces where the tube itself is in motion.

Stainless steel is a durable, cost-effective option for applications where a metallic environment is acceptable. For higher temperatures or more corrosive atmospheres, a nickel-based superalloy like Inconel is used for its superior strength and oxidation resistance.

Understanding the Trade-offs

Selecting the right material involves balancing performance, durability, and cost. No single material is perfect for every scenario.

Temperature vs. Purity

Alumina tubes provide unmatched temperature resistance, but standard-purity grades can sometimes be a source of contamination for ultra-sensitive materials. Quartz offers exceptional purity but cannot be used at the same extreme temperatures as alumina.

Durability vs. Inertness

Metal tubes are robust and can withstand mechanical stress far better than ceramics or glass. However, they are reactive and can contaminate samples. Ceramic and quartz tubes are highly inert but are brittle and can crack from severe thermal shock or physical impact.

Process Atmosphere Compatibility

The ability to hold a vacuum or contain specific process gases is critical. Quartz and alumina tubes are excellent for high-vacuum applications (down to 10⁻⁵ torr). Metal tubes are also suitable, but their outgassing properties must be considered for high-vacuum work.

Making the Right Choice for Your Goal

Selecting the correct tube material is a foundational step for ensuring the safety, accuracy, and success of your thermal process.

- If your primary focus is extreme temperatures (above 1200°C): Choose an alumina or mullite ceramic tube for its superior thermal stability.

- If your primary focus is sample purity at moderate heat (up to 1200°C): A fused quartz tube is the standard choice for its excellent chemical inertness.

- If your primary focus is mechanical durability or a metallic environment: A stainless steel or Inconel tube provides the necessary robustness, especially for rotary systems.

Understanding these core material properties empowers you to select a furnace configuration that guarantees the integrity and success of your work.

Summary Table:

| Material Type | Common Examples | Max Temperature | Key Characteristics | Best For |

|---|---|---|---|---|

| Ceramic | Alumina, Mullite | Up to 1800°C | Extreme heat resistance, chemical inertness | Sintering, crystal growth, high-temp annealing |

| Glass | Fused Quartz | Up to 1200°C | High purity, excellent thermal shock resistance | Semiconductor research, sensitive materials |

| Metal | Stainless Steel, Inconel | Varies by alloy | Mechanical durability, oxidation resistance | Rotary furnaces, metallic environments |

Need a Custom Tube Furnace Solution?

Choosing the right work tube material is critical for your experiment's success. At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced high-temperature furnace solutions tailored to your unique requirements.

Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, and Vacuum & Atmosphere Furnaces, complemented by strong deep customization capabilities. Whether you need extreme temperature stability with alumina, ultra-high purity with quartz, or mechanical durability with metal alloys, we can engineer the perfect system for your lab.

Contact us today to discuss your specific thermal processing needs and let our experts help you achieve precise, reliable results.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency