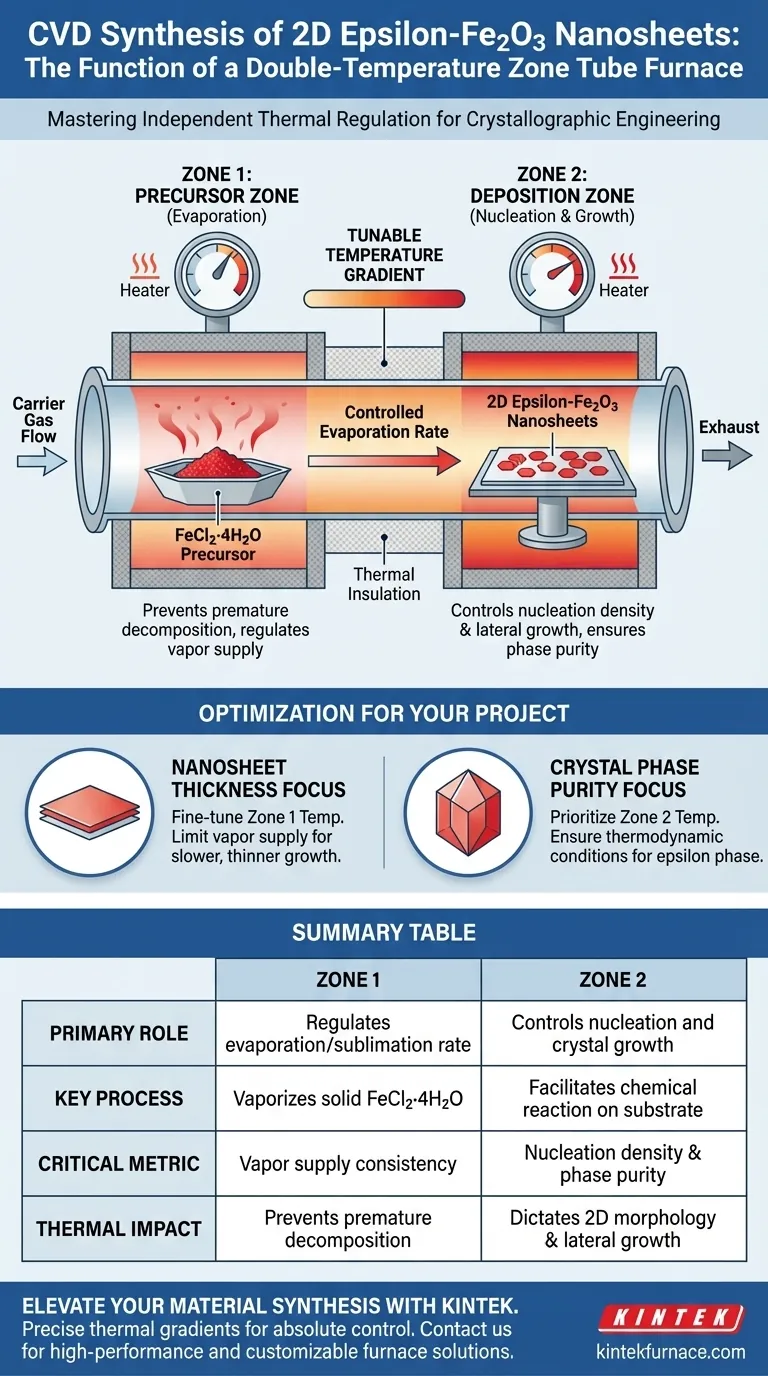

Independent thermal regulation is the defining function of a double-temperature zone tube furnace in the synthesis of 2D epsilon-Fe2O3 nanosheets. By separating the heating chamber into two distinct regions, this equipment allows you to simultaneously control the evaporation rate of the precursor (such as FeCl2·4H2O) in the first zone and the nucleation kinetics of the nanosheets in the second.

The dual-zone configuration effectively decouples the source material's evaporation from the product's formation. This separation creates a tunable temperature gradient essential for balancing the vapor supply with the specific energy requirements needed to grow high-quality, morphologically consistent 2D nanosheets.

The Mechanism of Dual-Zone Control

In a standard Chemical Vapor Deposition (CVD) process, the conditions required to vaporize a solid precursor rarely match the conditions required to grow a crystal on a substrate. A double-temperature zone furnace solves this by isolating these two critical phases.

Zone 1: Regulating Precursor Evaporation

The first zone is dedicated to the precursor material, typically FeCl2·4H2O in this specific synthesis.

The function of this zone is to heat the source material to a precise point where it sublimates or evaporates at a controlled rate.

By maintaining this zone independently, you prevent the precursor from decomposing too early or vaporizing too rapidly, which would flood the system with excess reactant.

Zone 2: Controlling Deposition Kinetics

The second zone is the deposition zone, where the substrate is located and the actual synthesis of 2D epsilon-Fe2O3 occurs.

This zone is maintained at a different, often higher, temperature designed specifically to facilitate the chemical reaction and subsequent crystallization on the substrate.

Precise thermal control here dictates the nucleation density and the lateral growth of the nanosheets, ensuring the formation of the specific epsilon phase rather than other iron oxide polymorphs.

The Role of the Temperature Gradient

Between these two zones lies a critical temperature gradient.

This gradient, combined with the flow of a carrier gas, guides the vaporized precursor from the source zone to the deposition zone.

Proper management of this gradient ensures that the vapor travels downstream without condensing prematurely on the tube walls before reaching the target substrate.

Understanding the Trade-offs

While a double-temperature zone furnace offers superior control compared to a single-zone setup, it introduces complexity that must be managed carefully.

Complexity of Parameter Optimization

With two independent heating zones, you double the number of thermal variables you must stabilize.

You must find the perfect ratio between the evaporation temperature (Zone 1) and the reaction temperature (Zone 2).

A mismatch can lead to poor morphology; for example, if Zone 1 is too hot relative to Zone 2, the substrate may become oversaturated, leading to bulk growth rather than thin 2D nanosheets.

Optimization for Your Project

To maximize the utility of a double-temperature zone furnace for epsilon-Fe2O3 synthesis, align your thermal settings with your specific structural goals.

- If your primary focus is Nanosheet Thickness: Focus on fine-tuning the precursor zone temperature to limit the vapor supply rate, ensuring slower, thinner growth.

- If your primary focus is Crystal Phase Purity: Prioritize the precision of the deposition zone temperature to ensure the thermodynamic conditions strictly favor the epsilon-Fe2O3 phase over others.

By mastering the gradient between these two zones, you transition from simple heating to true crystallographic engineering.

Summary Table:

| Feature | Zone 1 (Precursor Zone) | Zone 2 (Deposition Zone) |

|---|---|---|

| Primary Role | Regulates evaporation/sublimation rate | Controls nucleation and crystal growth |

| Key Process | Vaporizes solid FeCl2·4H2O | Faciliates chemical reaction on substrate |

| Critical Metric | Vapor supply consistency | Nucleation density & phase purity |

| Thermal Impact | Prevents premature decomposition | Dictates 2D morphology & lateral growth |

Elevate Your Material Synthesis with KINTEK

Precise thermal gradients are the key to mastering 2D material synthesis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to give you absolute control over your research parameters. Whether you need standard configurations or a customizable solution for your unique high-temperature lab needs, our furnaces deliver the stability and accuracy your project demands.

Ready to optimize your CVD process? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Wuhong Xue, Xiaohong Xu. Stable antivortices in multiferroic ε-Fe2O3 with the coalescence of misaligned grains. DOI: 10.1038/s41467-025-55841-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the key differences between single-zone and multi-zone vertical tube furnaces? Choose the Right Furnace for Your Lab

- What role do laboratory tube or muffle furnaces play in simulating SCM435 steel behavior? Optimize Material Research

- When did tube furnaces originate and what drove their development? Discover the Engineered Solution for Precise Heat

- What is the advantage of a three-zone tube furnace? Achieve Larger, More Uniform Heating for Your Processes

- What is the function of a Tube Furnace during molybdenum carbide synthesis? Master Catalyst Carbonization

- What role does a high-temperature tube furnace play in the final thermal treatment of Na3(VO1-x)2(PO4)2F1+2x?

- How do you rejuvenate vacuum tubes? A Last-Resort Guide to Salvaging Rare Components

- How can tube furnaces be configured for different laboratory needs? Optimize Your Lab's Thermal Processes