The first tube furnaces emerged in the early 20th century, developed to solve a pressing problem that was holding back scientific and industrial progress. Their creation was driven directly by the growing demand for precise, uniform, and atmospherically controlled high-temperature environments, which older heating methods could not provide.

The development of the tube furnace was not merely an incremental improvement; it was a foundational shift. It moved thermal processing from a brute-force art to a controllable science, enabling the creation and analysis of materials that were previously impossible to study.

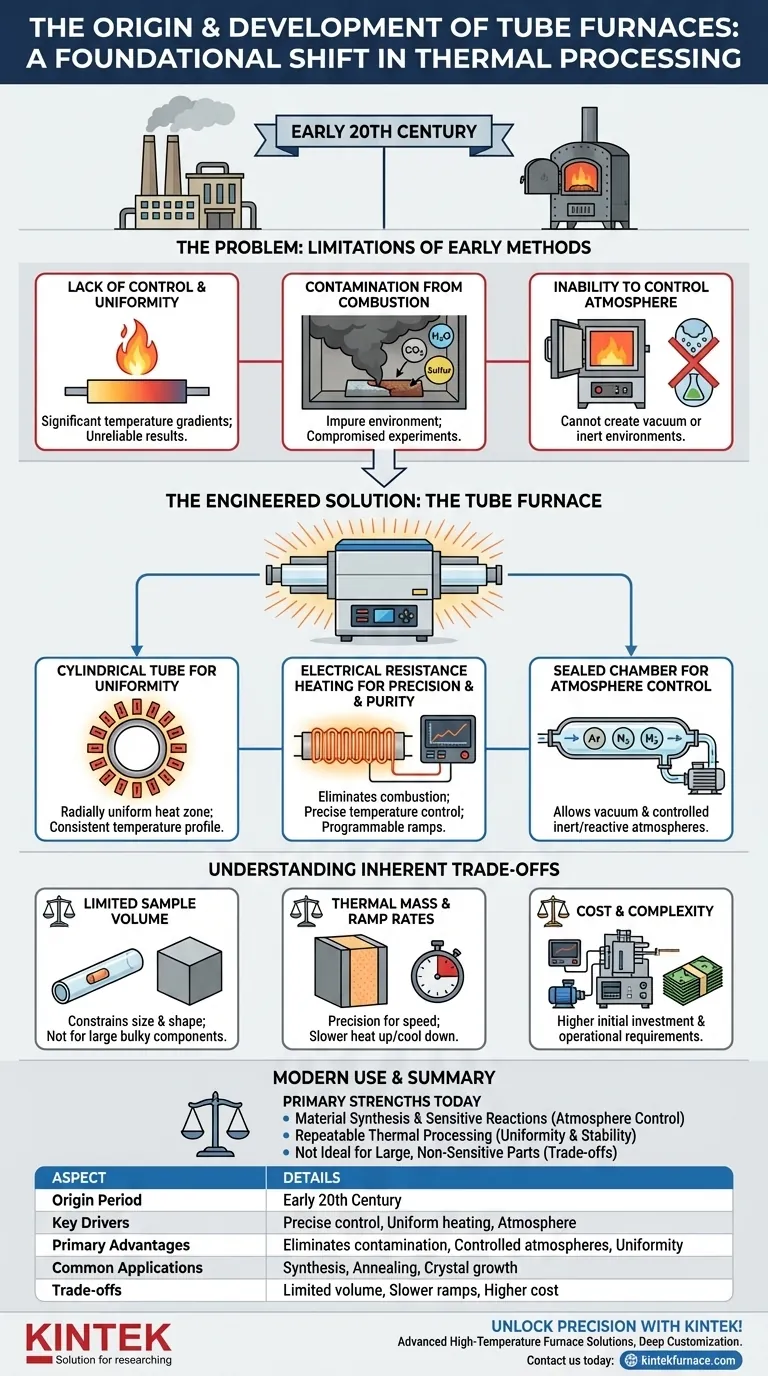

The Problem: Limitations of Early Heating Methods

Before the advent of the modern tube furnace, heating materials for research or industrial processes was an imprecise and often "dirty" affair. The methods available, typically based on direct combustion, presented significant obstacles to scientific advancement.

Lack of Temperature Control and Uniformity

Early heating relied on open flames or simple combustion-fired ovens. These methods created significant temperature gradients, meaning one part of a sample could be much hotter than another. This lack of uniformity made repeatable experiments and reliable manufacturing nearly impossible.

Contamination from Combustion

Heating with gas, oil, or coal introduces byproducts of combustion directly into the heating chamber. These reactive gases (like carbon dioxide, water vapor, and sulfur compounds) could contaminate or unintentionally react with the material being processed, compromising the integrity of experiments and the purity of products.

Inability to Control the Atmosphere

Many modern material processes, such as annealing or crystal growth, require a specific atmosphere—either a vacuum or an inert gas like argon. Combustion-based systems could not provide this controlled environment, severely limiting the scope of material science research.

The Tube Furnace as the Engineered Solution

The tube furnace was designed specifically to overcome these three fundamental limitations. Its design is a direct answer to the needs for precision, purity, and atmospheric control.

The Cylindrical Tube for Uniformity

The core of the design is a ceramic or metallic tube that contains the sample. Heating elements are placed symmetrically around this tube, creating a radially uniform heat zone. This geometry is far superior to a simple box oven for achieving a consistent temperature profile along the sample's length.

Electrical Resistance Heating for Precision and Purity

The rise of reliable electricity in the early 20th century was the key enabler. By using electrical resistance heating elements (like nichrome or, later, silicon carbide), furnace designers eliminated combustion entirely. This immediately solved the contamination problem.

Furthermore, electrical current can be controlled with incredible precision. This allowed for stable setpoint temperatures and programmable heating and cooling ramps—the very definition of precise thermal control.

The Sealed Chamber for Atmosphere Control

A tube can be easily sealed at both ends. This simple but profound design feature allows for the two most critical functions in modern materials processing: pulling a vacuum to remove atmospheric contaminants and introducing a specific process gas (e.g., nitrogen, hydrogen, argon) to create a controlled, reactive, or inert environment.

Understanding the Inherent Trade-offs

While revolutionary, the design of the tube furnace is optimized for a specific purpose, which introduces practical trade-offs. Understanding these is key to using the equipment correctly.

Limited Sample Volume

The defining feature of a tube furnace—the tube—also constrains the size and shape of the sample. For processing large or bulky components, a box furnace is often a more practical choice, though it may sacrifice some temperature uniformity.

Thermal Mass and Ramp Rates

The heavy insulation required to achieve high temperatures and excellent stability gives the furnace significant thermal mass. This means tube furnaces generally cannot heat up or cool down as quickly as other systems. The trade-off is precision for speed.

Cost and Complexity

A system designed for high precision and atmospheric control is inherently more complex and expensive than a simple oven. The need for temperature controllers, vacuum pumps, and gas flow systems adds to the overall cost and operational requirements.

How This History Informs Modern Use

The historical drivers behind the tube furnace's development directly correlate to the reasons you would choose one today. The original problems it was designed to solve—precision, purity, and atmosphere control—remain its primary strengths.

- If your primary focus is material synthesis or sensitive chemical reactions: The tube furnace's unparalleled atmosphere control is the reason to choose it.

- If your primary focus is repeatable thermal processing like annealing or tempering: The excellent temperature uniformity and stability ensure that every run is identical.

- If your primary focus is simply heating large, non-sensitive parts: The trade-offs in sample volume and cost suggest a simpler box or convection oven may be a better tool for the job.

Understanding its origin reveals the tube furnace not as just another heater, but as a purpose-built instrument that unlocked the door to modern materials science.

Summary Table:

| Aspect | Details |

|---|---|

| Origin Period | Early 20th century |

| Key Drivers | Demand for precise temperature control, uniform heating, and atmospheric control |

| Primary Advantages | Eliminates contamination, enables controlled atmospheres, ensures temperature uniformity |

| Common Applications | Material synthesis, annealing, crystal growth, thermal processing |

| Trade-offs | Limited sample volume, slower ramp rates, higher cost and complexity |

Unlock Precision in Your Lab with KINTEK's Advanced Tube Furnaces!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need precise temperature control, uniform heating, or specialized atmosphere environments for material synthesis and thermal processing, KINTEK delivers reliable, tailored solutions that enhance efficiency and accuracy in your research.

Contact us today to discuss how our tube furnaces can drive your scientific advancements and meet your specific needs!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety