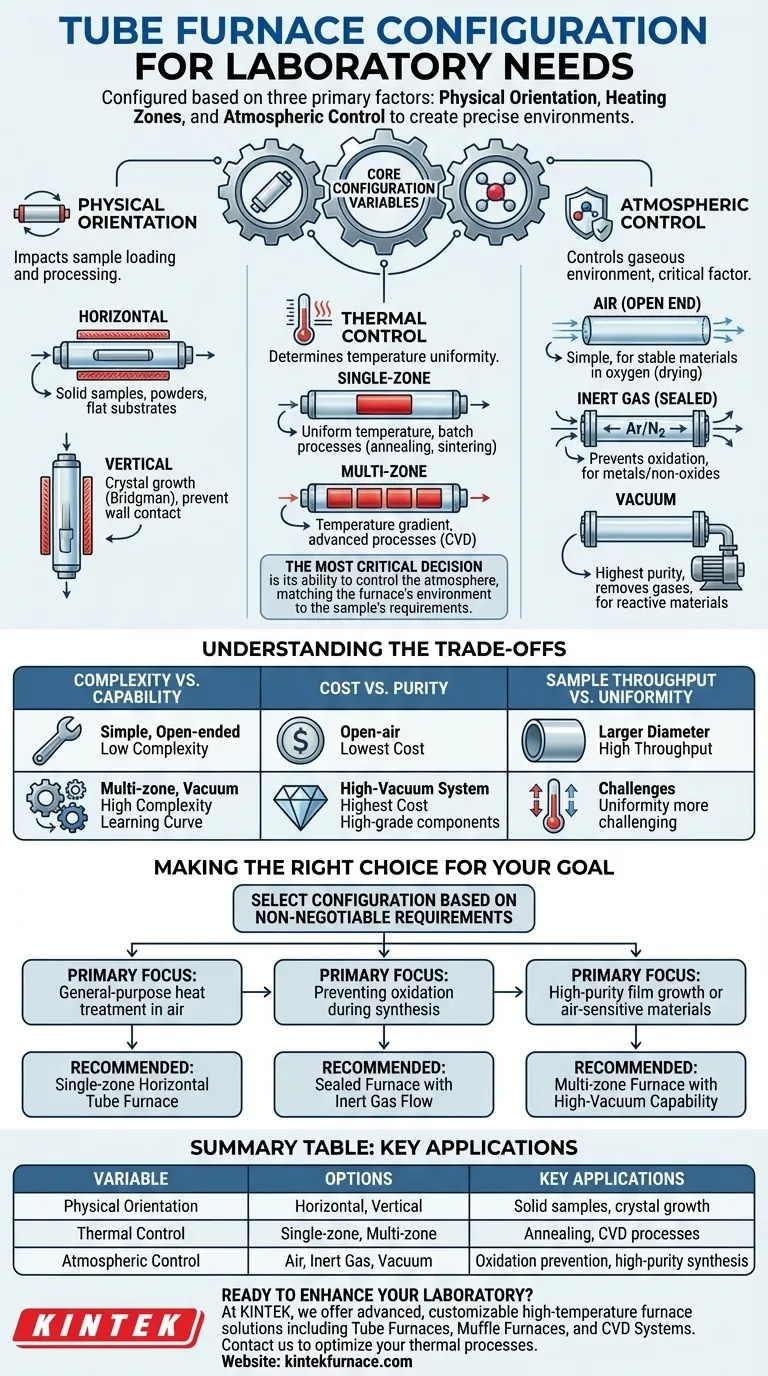

In essence, tube furnaces are configured based on three primary factors: their physical orientation, the number of heating zones, and their capacity for atmospheric control. These elements are not chosen arbitrarily; they are selected to create the precise thermal and chemical environment required for a specific material process, from simple heat treatment to complex crystal growth.

The most critical decision in configuring a tube furnace is not about its maximum temperature, but about its ability to control the atmosphere. The right configuration directly matches the furnace's environmental controls—be it air, inert gas, or vacuum—to the chemical stability and processing requirements of your sample.

Core Configuration Variables

Understanding the fundamental options is the first step in selecting the right tool for your research. Each variable serves a distinct purpose and directly impacts the outcome of your experiment.

Physical Orientation: Horizontal vs. Vertical

The orientation of the furnace tube dictates how a sample is loaded and processed.

Horizontal furnaces are the most common configuration. They are simple to load and operate, making them ideal for processing solid samples, powders in boats, or substrates that can lie flat.

Vertical furnaces are used for specialized applications. They are advantageous for processes where gravity is beneficial, such as crystal growth from a melt (Bridgman technique) or when it is critical to prevent the sample from touching the tube walls. This orientation can also minimize thermal convection currents.

Thermal Control: Single-Zone vs. Multi-Zone

The level of temperature control is determined by the number of independent heating zones.

Single-zone furnaces are designed to create a uniform temperature across a central "hot zone." They are perfect for batch processes like annealing, calcination, or sintering, where the entire sample needs to be held at one specific temperature.

Multi-zone furnaces feature two or more independent heating elements along the length of the tube. This allows for the creation of a precise temperature gradient. This capability is essential for advanced processes like chemical vapor deposition (CVD), where different temperature zones are needed to vaporize precursors and deposit films.

Atmospheric Control: The Critical Factor

The ability to control the gaseous environment inside the tube is often the most important configuration choice.

Air Atmosphere (Open End) is the simplest setup, suitable for materials that are stable when heated in the presence of oxygen. This is common for drying, binder burnout, or specific types of oxide material synthesis.

Controlled Atmosphere (Inert Gas) involves sealing the tube ends with flanges and flowing a gas like nitrogen or argon through it. This displaces oxygen and prevents unwanted oxidation or reactions, which is critical for processing many metals, alloys, and non-oxide ceramics.

Vacuum Atmosphere provides the highest level of purity. By connecting a vacuum pump, nearly all gas molecules are removed from the tube. This is necessary for processing highly reactive materials or for applications in physics and chemistry where gas-phase interactions must be eliminated.

Understanding the Trade-offs

A more capable furnace is not always the better choice. Each configuration comes with compromises in complexity, cost, and operational requirements.

Complexity vs. Capability

A simple, open-ended horizontal furnace is easy to operate and maintain. In contrast, a multi-zone vacuum furnace is a complex system requiring specialized flanges, seals, vacuum pumps, and controllers. This increases the operational learning curve and the number of potential failure points.

Cost vs. Purity

The cost of a furnace system increases dramatically with its level of atmospheric control. An open-air furnace is the most affordable. Adding gas flow capabilities increases the price, and a high-vacuum system is the most significant investment due to the need for high-grade pumps, gauges, and leak-tight components.

Sample Throughput vs. Uniformity

Larger diameter tubes can process more material at once, increasing throughput. However, achieving perfect temperature uniformity across a larger cross-section can be more challenging than in a smaller tube. This is a critical consideration for processes sensitive to slight temperature variations.

Making the Right Choice for Your Goal

Select your furnace configuration based on the non-negotiable requirements of your material and process.

- If your primary focus is general-purpose heat treatment in air: A single-zone horizontal tube furnace is the most practical and cost-effective choice.

- If your primary focus is preventing oxidation during material synthesis: You need a furnace with sealed flanges configured for inert gas flow.

- If your primary focus is high-purity film growth or processing air-sensitive materials: A multi-zone furnace with high-vacuum capability is essential for precise thermal and atmospheric control.

Ultimately, configuring a tube furnace is about creating a controlled and repeatable environment to achieve your desired scientific outcome.

Summary Table:

| Configuration Variable | Options | Key Applications |

|---|---|---|

| Physical Orientation | Horizontal, Vertical | Solid samples, crystal growth |

| Thermal Control | Single-zone, Multi-zone | Annealing, CVD processes |

| Atmospheric Control | Air, Inert Gas, Vacuum | Oxidation prevention, high-purity synthesis |

Ready to enhance your laboratory's capabilities with a tailored tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your thermal processes and boost efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision