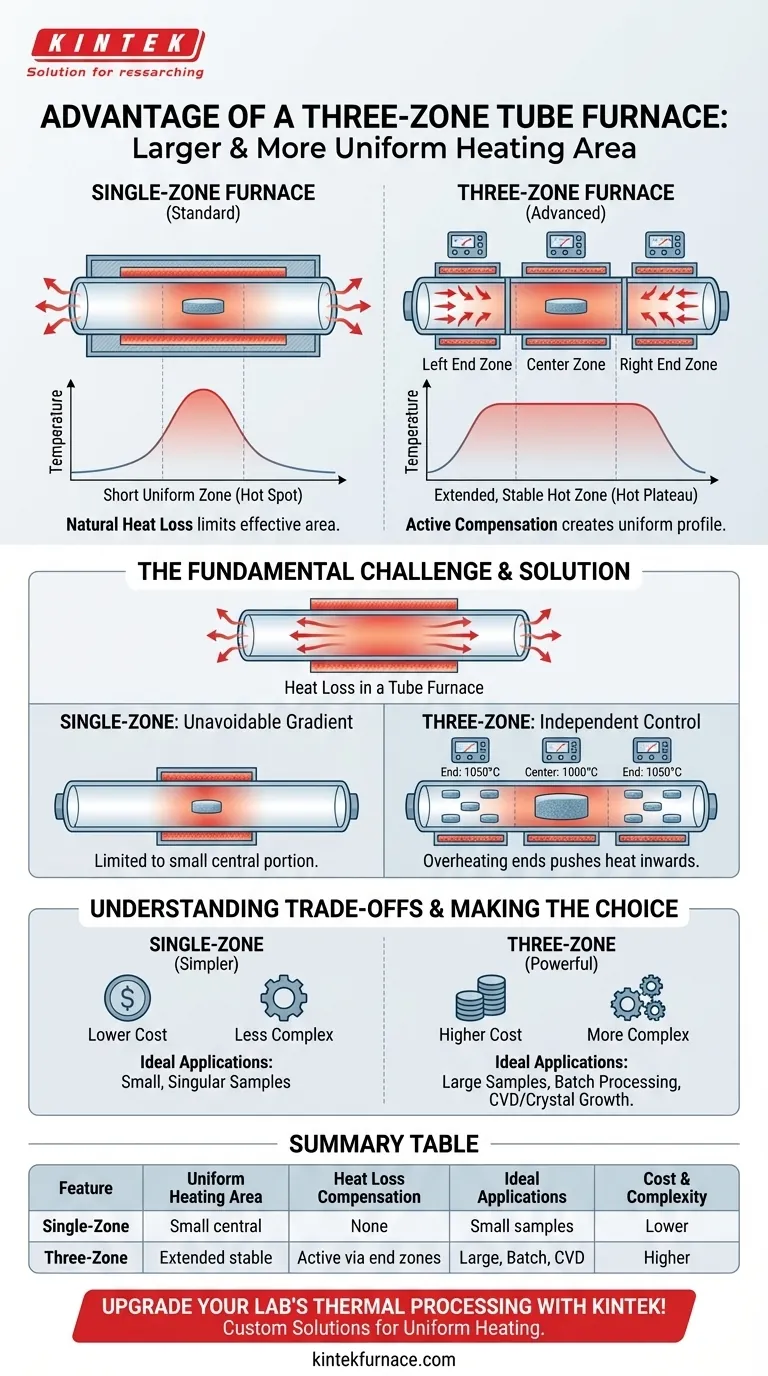

The primary advantage of a three-zone tube furnace is its ability to create a significantly larger and more uniform heating area. Unlike a standard single-zone furnace, which is only truly uniform in its very center, a three-zone model uses two additional heating zones at the ends to actively compensate for natural heat loss. This results in a stable, consistent temperature profile along a much greater length of the processing tube.

A standard furnace has one hot spot. A three-zone furnace creates a long, flat "hot plateau." It achieves this by using independent end-zone heaters to counteract the inevitable heat loss that occurs at the tube's openings, a problem that limits the effective working area of single-zone designs.

The Fundamental Challenge: Heat Loss in a Tube Furnace

All tube furnaces, by their nature, face a challenge with thermal uniformity. Understanding this is key to appreciating the value of a multi-zone design.

The Natural Temperature Profile

A single-zone furnace has one set of heating elements wrapped around its center. Heat naturally escapes from the open or capped ends of the tube into the cooler, ambient environment.

This creates an unavoidable temperature gradient. The furnace is hottest at its geometric center and progressively cooler toward the ends, limiting the truly uniform hot zone to a small central portion.

The Impact on Processing

This short uniform zone means that any sample or process must be confined to the very middle of the furnace to ensure consistent thermal treatment. This severely limits the size of a sample, the number of samples in a batch, or the length over which a continuous process (like chemical vapor deposition) can occur.

How a Three-Zone Furnace Solves the Problem

A three-zone furnace directly confronts the issue of end losses by dividing the furnace into three independently controlled sections.

Independent Heating Zones

The furnace is composed of a main center zone and two smaller end zones (left and right). Each zone has its own heating elements and a dedicated thermocouple and controller.

Compensating for Heat Loss

To create a long, uniform hot zone, operators can set the end zones to a slightly higher temperature than the center. This "overheating" at the ends pushes extra heat inwards, precisely counteracting the thermal energy that would otherwise escape.

This active compensation effectively flattens the temperature curve, preventing the typical drop-off seen at the ends of a single-zone furnace.

The Result: An Extended, Stable Hot Zone

The outcome is a uniform temperature profile that extends across a much greater portion of the tube's length. This allows for the reliable processing of larger samples, more consistent batch production, and processes that require a long, stable thermal environment.

Understanding the Trade-offs

While powerful, a three-zone furnace is not always the necessary choice. Objectivity requires acknowledging its trade-offs.

Increased Cost and Complexity

The addition of two extra heating zones, controllers, and thermocouples inherently increases the furnace's cost and operational complexity. Programming three zones requires more setup than programming one, though modern controllers have made this process very straightforward.

When a Single Zone Is Sufficient

For applications involving small, well-defined samples that can easily fit within the short uniform zone of a standard furnace, a single-zone model is often more than adequate. It is a simpler, more cost-effective solution when a large uniform area is not a critical requirement.

Making the Right Choice for Your Application

Your choice depends entirely on the scale and uniformity requirements of your thermal process.

- If your primary focus is processing small, singular samples: A single-zone furnace is the most cost-effective and practical choice, as the sample can be placed directly in the center.

- If your primary focus is processing large samples or multiple samples at once: A three-zone furnace is essential to ensure the entire batch experiences the same target temperature.

- If your primary focus is a process requiring a long, stable thermal profile (e.g., crystal growth or CVD): A three-zone furnace provides the superior control needed to establish and maintain this environment with high precision.

By understanding the principle of zone-based heat loss compensation, you can confidently select the right tool for your specific thermal processing goals.

Summary Table:

| Feature | Single-Zone Furnace | Three-Zone Furnace |

|---|---|---|

| Uniform Heating Area | Small central zone only | Extended length with stable temperature |

| Heat Loss Compensation | None | Active compensation via end zones |

| Ideal Applications | Small, singular samples | Large samples, batch processing, CVD |

| Cost and Complexity | Lower | Higher due to extra zones and controls |

Upgrade your lab's thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Tube Furnaces, Muffle Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for larger, uniform heating areas. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients